A refrigerator door panel bending mold

A technology for bending molds and door panels, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as strained hemming, refrigerator door hemming cannot be made inwardly, and refrigerator door hemming structure is complex, etc. Achieve the effect of simple hemming structure and easy unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

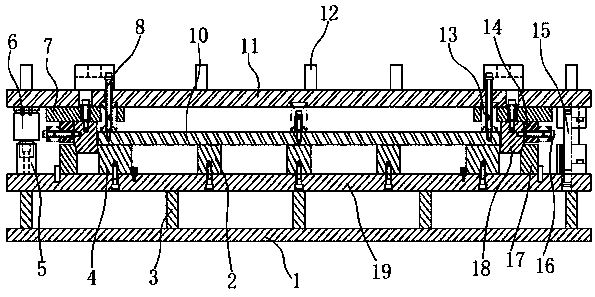

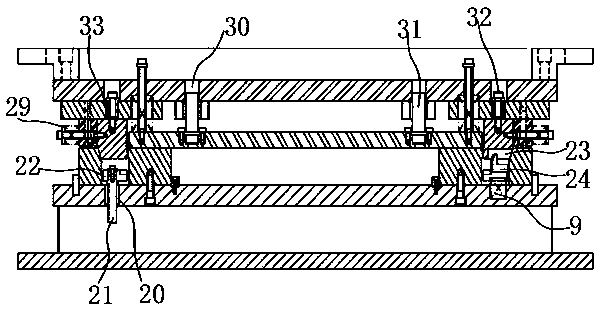

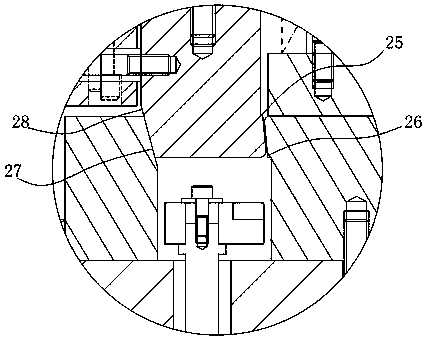

[0017] Embodiment: a refrigerator door panel bending mold, including upper die ribs 12, lower template 1, upper template 11, the lower template 1 is provided with a lower mold installation pad 3, and the lower mold installation pad 3 is topped A lower mold table panel 19 is provided on the surface, and a lower mold bending strip 4 is provided on the top surface of the lower mold table panel 19. The lower mold bending strips 4 are at least four and connected end to end, and the lower mold bending strips 4 The outer side is provided with a bending surface 26 extending from the outer side of the top of the lower mold bending bar 4 to the inner side of the bottom of the lower mold bending bar 4, and the lower mold table panel 19 on the outer side of the lower mold bending bar 4 is provided with a Drive block 17, the bottom of the upper template 11 is provided with an upper mold mounting base 7, the bottom of the upper mold mounting base 7 is provided with a reset back bar 14, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com