A fixture for thin-walled easily deformable squirrel cage parts

A technology that is easy to deform and parts, applied in the direction of metal processing machinery parts, clamping, manufacturing tools, etc., can solve problems such as clamping deformation of squirrel cage parts, and achieve the effect of enhancing rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

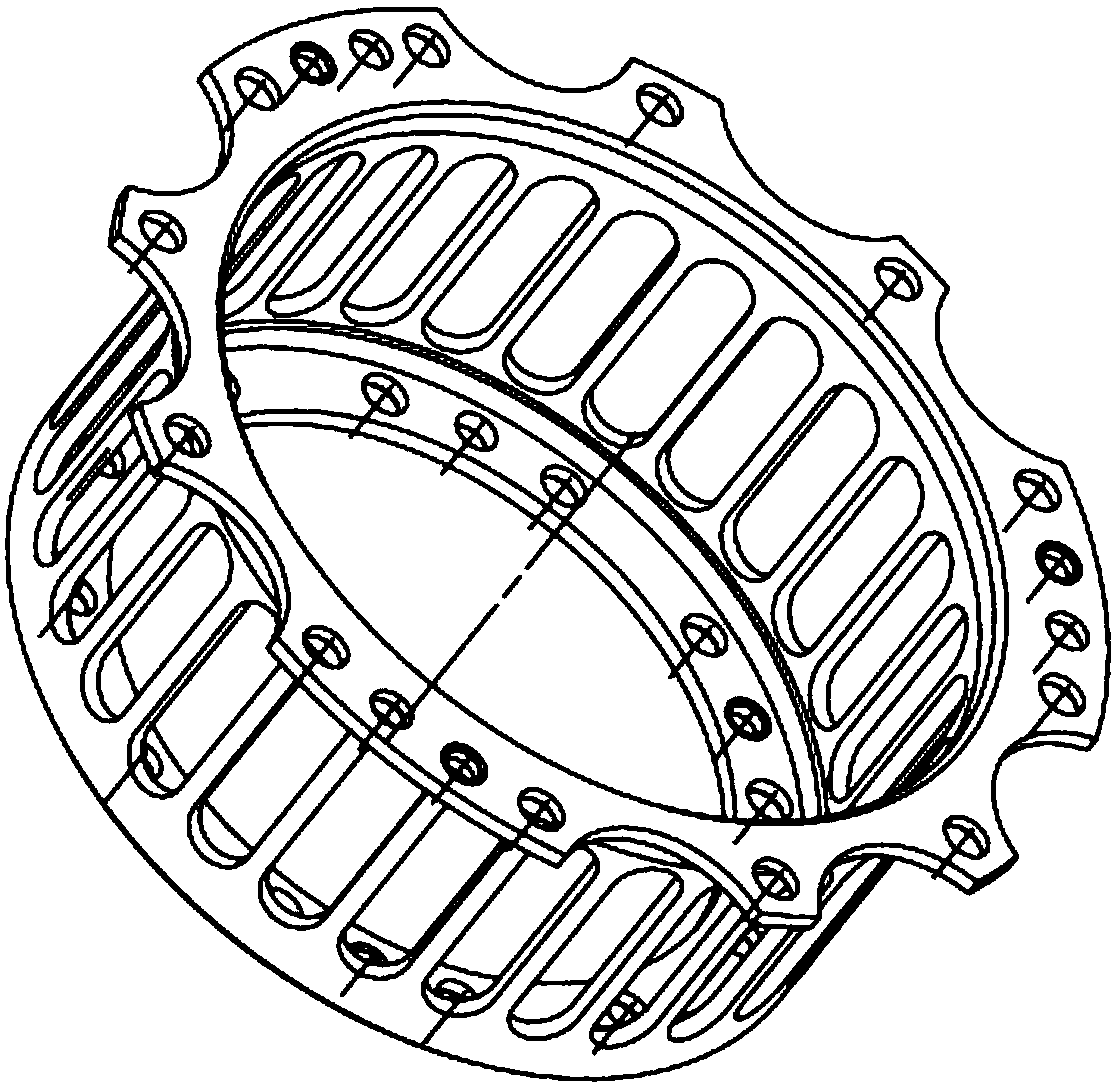

Image

Examples

Embodiment Construction

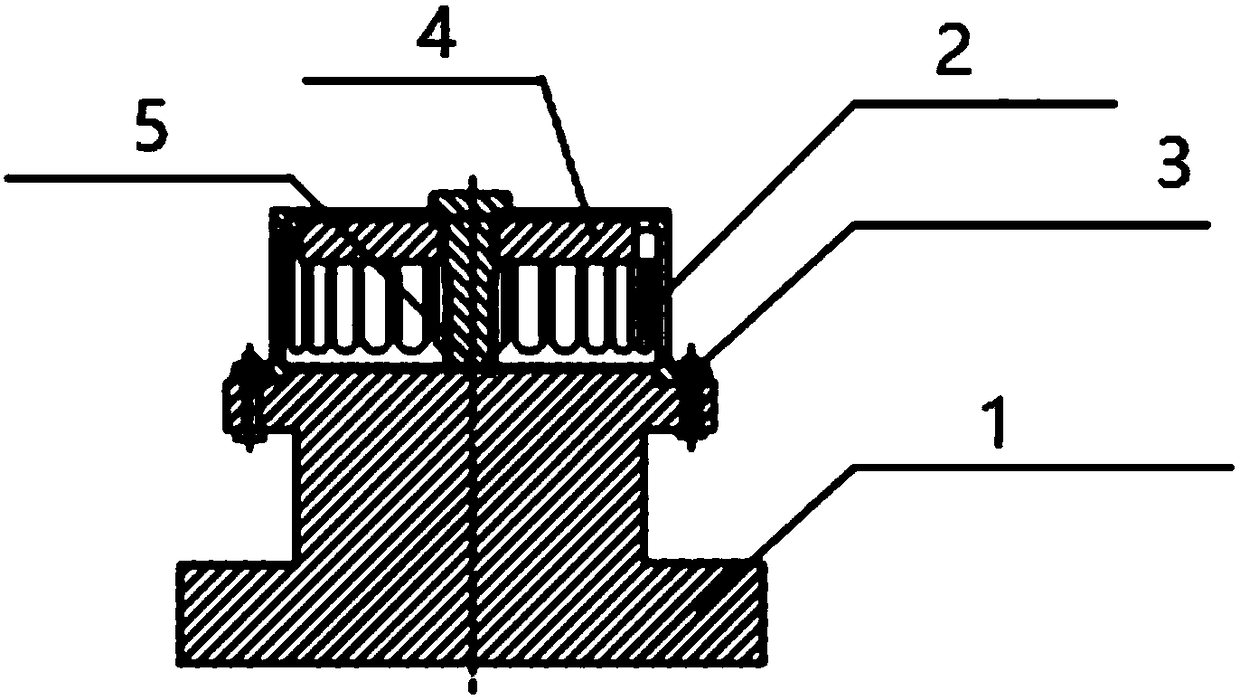

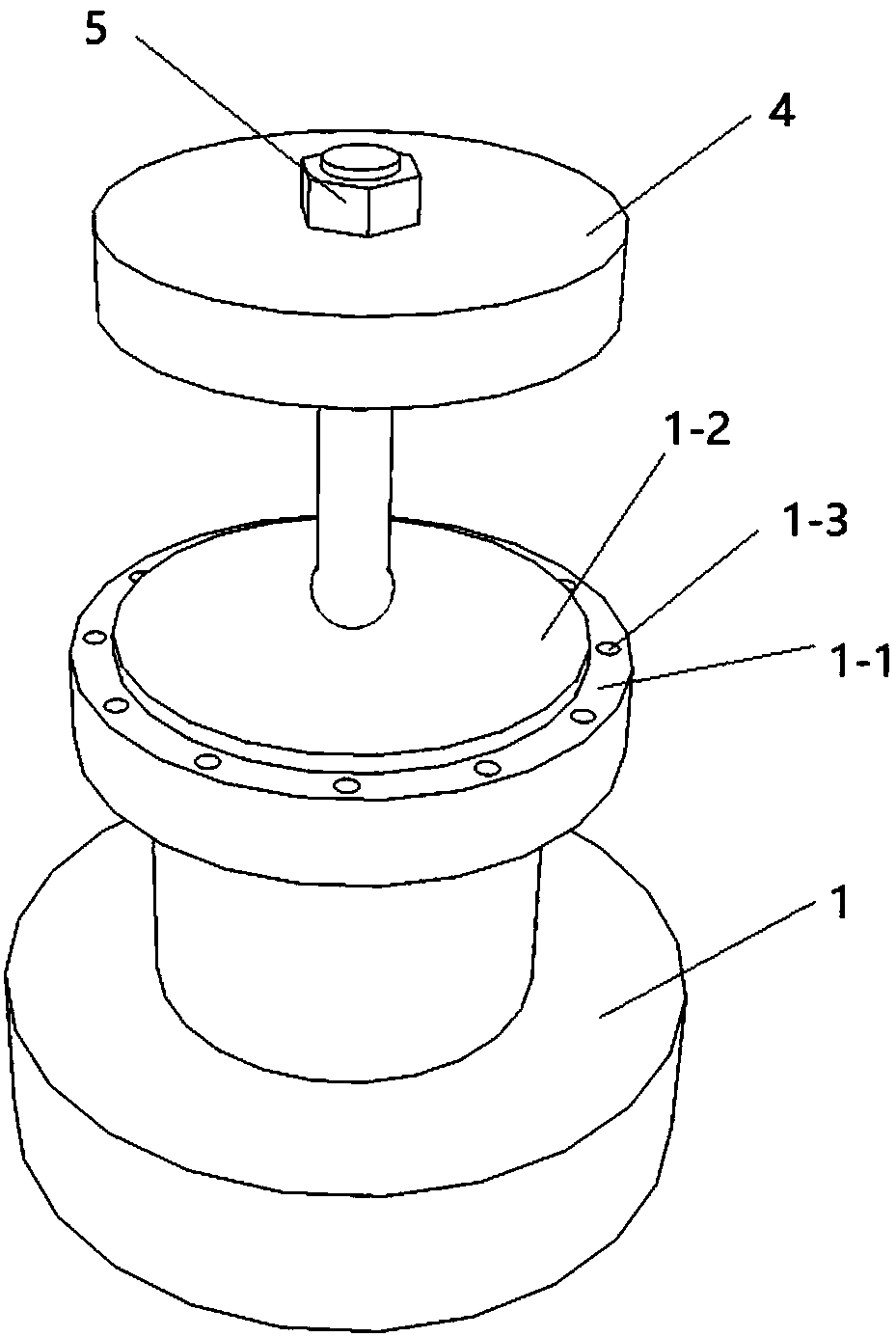

[0025] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0026] Such as figure 2 and 3 As shown, a fixture for thin-walled easily deformable squirrel cage parts includes a part positioning clamp body 1 and a clamp top plate 4, the longitudinal section of the part positioning clamp body 1 is I-shaped, and the upper end surface 1 of the part positioning clamp body 1- 1 is a circular plane, with screw holes 1-3 distributed in the circumferential direction of its edge, a cylindrical boss 1-2 on the upper end surface 1-1, the diameter of the boss 1-2 is equal to the inner cavity diameter of the squirrel cage part 2, two The fit of the latter is a clearance fit, which ensures that the squirrel cage parts are in a free state during positioning. The clamp clamping plate 4 is a cylindrical plate, with a threaded through hole on the central axis, and the clamping screw 5 is inside the threaded through hole, and the head of the cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com