Bearing support frame clamping device and clamping method thereof

A technology of bearing support frame and clamping device, applied in the direction of workpiece clamping device, manufacturing tools, etc., can solve problems such as clamping deformation, achieve the effect of solving clamping deformation and ensuring machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The invention provides a bearing support frame clamping device and a clamping method thereof. In order to make the object, technical solution and effect of the present invention more clear and definite, the present invention will be further described in detail below with reference to the accompanying drawings and examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

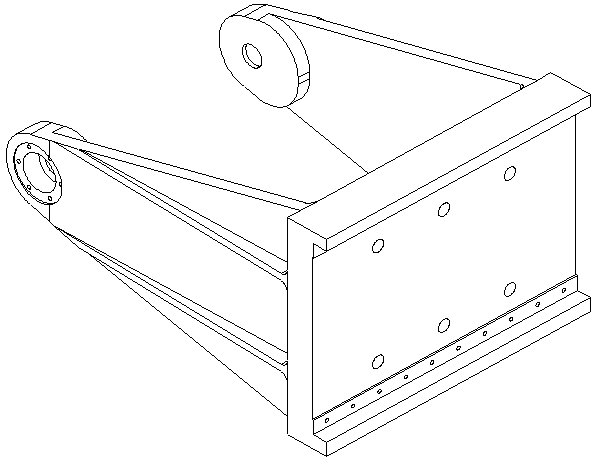

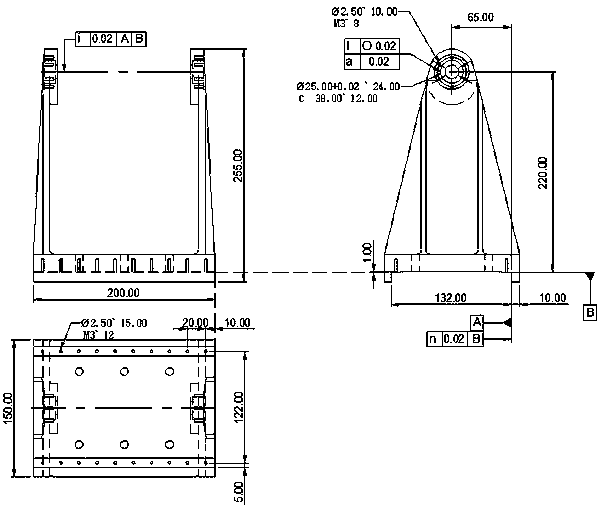

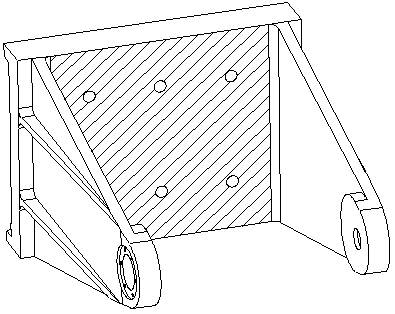

[0031] Such as figure 1 The bearing supports of the type shown are generally divided into casting, aging, rough machining, artificial aging, finishing and other stages according to the usual process route. In this embodiment, it is assumed that the bearing supports have undergone rough machining and artificial aging. image 3 as shown ( image 3 With figure 1 Corresponding reverse side, to show the reference of the shadow surface used later), the shadow surface has been processed into a reference...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com