Method for finish machining of inner hole of ultra-long copper bush on deep hole drilling and boring machine

A technology of deep hole drilling and boring machine and copper bushing, which is applied in the direction of boring/drilling, drilling/drilling equipment, metal processing equipment, etc., which can solve the difficulty of achieving high precision in one clamping and the difficulty of deep hole finishing Large and demanding problems, to achieve the effects of reducing adverse effects, shortening contact, and high processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] This embodiment provides a method for finishing the inner hole of the ultra-long copper sleeve 1 on a deep hole drilling and boring machine. The specific steps are as follows:

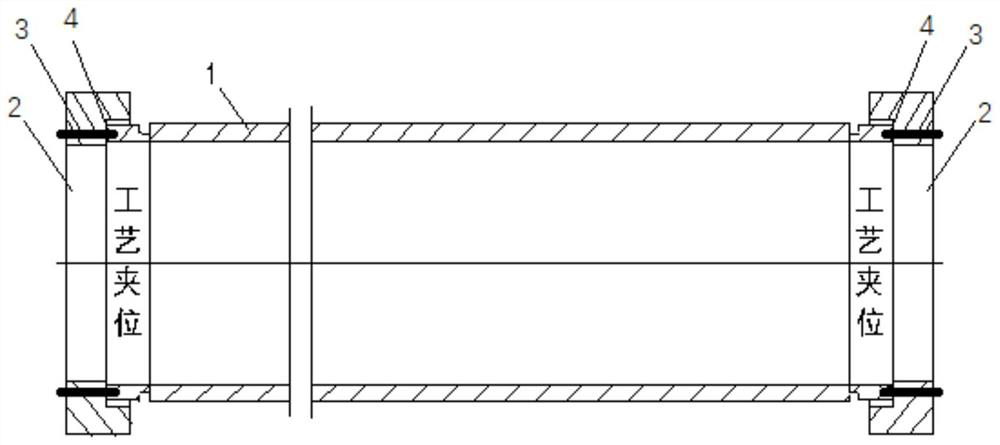

[0044] Step 1, such as figure 1 As shown, the two ends of the copper sleeve 1 are assembled with the tooling 2 for the deep hole of the copper sleeve, and the tooling 2 for the deep hole of the copper sleeve is clamped by the jaws of the deep hole machine tool, so as to realize the clamping of the copper sleeve 1 on the deep hole drilling and boring machine .

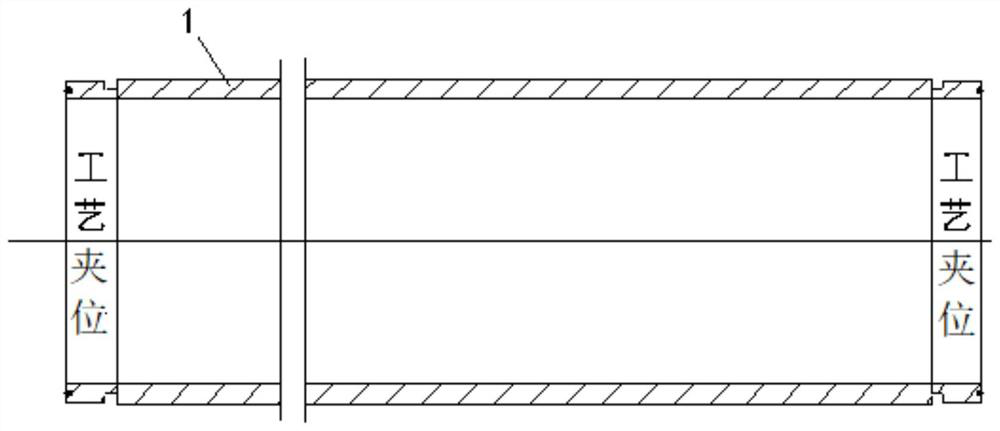

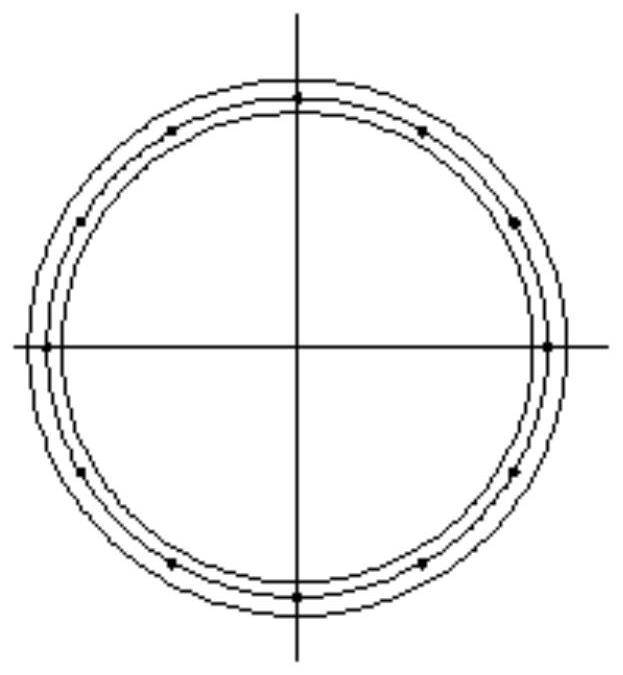

[0045] Such as figure 2 , 3 As shown, the copper sleeve 1 consists of three parts: the process clamps at both ends and the main part of the copper sleeve in the middle. The length of the process clamps at both ends of the copper sleeve 1 is about 50mm, = there is a ring-mounted unloading groove on the process clamp, The purpose of the unloading groove is to eliminate the adverse effect of the clamping force on the body of the copper s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com