A light bulb exhaust pipe secondary burning tip jig

A technology for exhaust pipes and light bulbs, applied in the field of burning tips, can solve problems such as affecting assembly and scrapping of light bulbs, and achieve the effect of eliminating potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

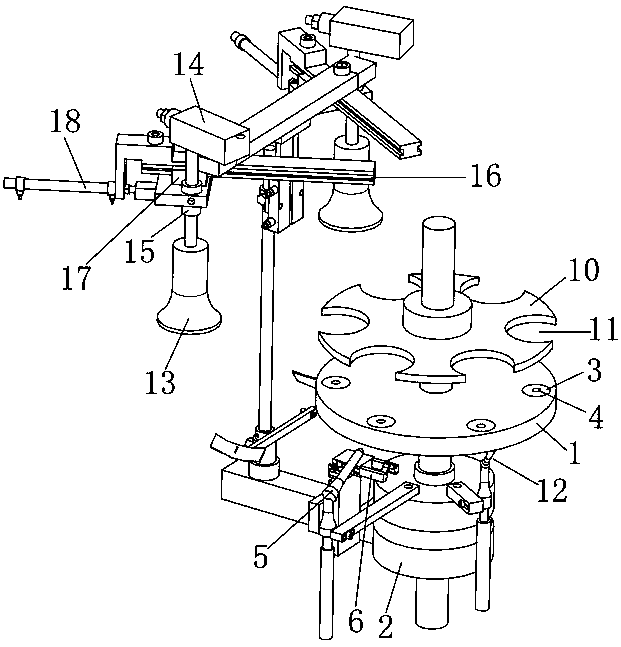

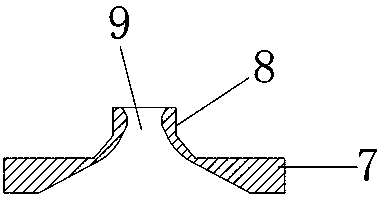

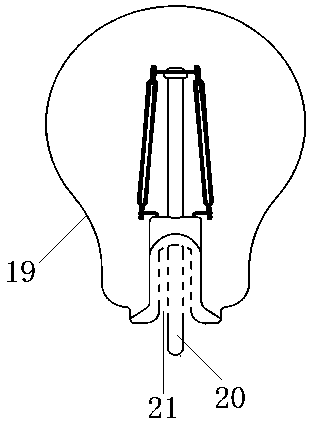

[0029] Embodiment 1: A light bulb exhaust pipe secondary burning tip fixture of this embodiment, such as figure 1 As shown, it includes a bulb conveying device, a first flame nozzle 5, a second flame nozzle 12 and a manipulator 6, and the bulb conveying device includes a positioning disc 1, a blister disc 10 and a drive positioning disc 1, a blister disc 10 The first drive mechanism 2 that rotates coaxially, the positioning disc 1 is provided with six grooves 3 for the bottom of the bulb to be inserted, the six grooves 3 are located on the same circle with the center of the positioning disc as the center, and the six grooves The grooves 3 are arranged at equal intervals, and the bottom of the groove 3 is provided with a first through hole for the exhaust pipe at the bottom of the bulb to pass through. The position is provided with an opening 11 matching the upper part of the bulb, and the groove 3 is provided with an isolation part for isolating the bulb shell from the exhaust...

Embodiment 2

[0041] Embodiment 2: A light bulb exhaust pipe secondary burner fixture of this embodiment, the position corresponding to the first through hole on the bubble holder disc is provided with a third through hole matching with the upper part of the light bulb, and the rest of the structure and implementation Example 1 is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com