Low-altitude illuminating lamp structure for bridge

A technology of lighting lamps and lighting fixtures, which is applied to lighting devices, fixed lighting devices, lighting and heating equipment, etc., can solve the problems of the service life of bridge low-altitude lighting lamps, cumbersome disassembly of lamp bodies, troublesome staff, etc., and achieve simple structure , Convenient operation, and the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

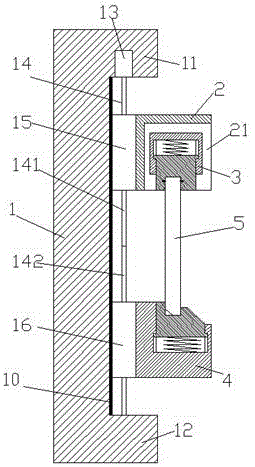

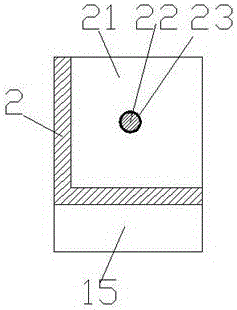

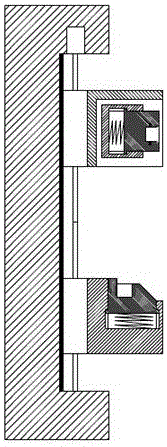

[0021] Such as Figure 1-Figure 7 As shown, a bridge low-altitude lighting structure of the present invention includes a frame body 1, and the frame body 1 is provided with a first wedging block 11 and a second wedging block 12, and the inside of the first wedging block 11 is An electric motor 13 is fixed, and the bottom of the electric motor 13 is screwed with a screw rod 14, and the screw rod 14 extends toward the second wedging block 12 and connects with the second wedging block 12. screw connection, the screw rod 14 is made up of a first screw rod 141 and a second screw rod 142, and the first screw rod 141 and the second screw rod 142 are set on the opposite side of the screw thread, so that the The first sliding block 15 and the second sliding block 16 move closer to or away from each other, and the first screw rod 141 and the second screw rod 142 are threadedly connected with the first sliding block 15 and the second sliding block respectively. 16. The first sliding blo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com