A mechanical pump noise reduction device

A mechanical pump and noise reduction technology, which is applied to mechanical equipment, components of pumping devices for elastic fluids, pump components, etc., can solve secondary noise pollution and other problems, and achieve optimal results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

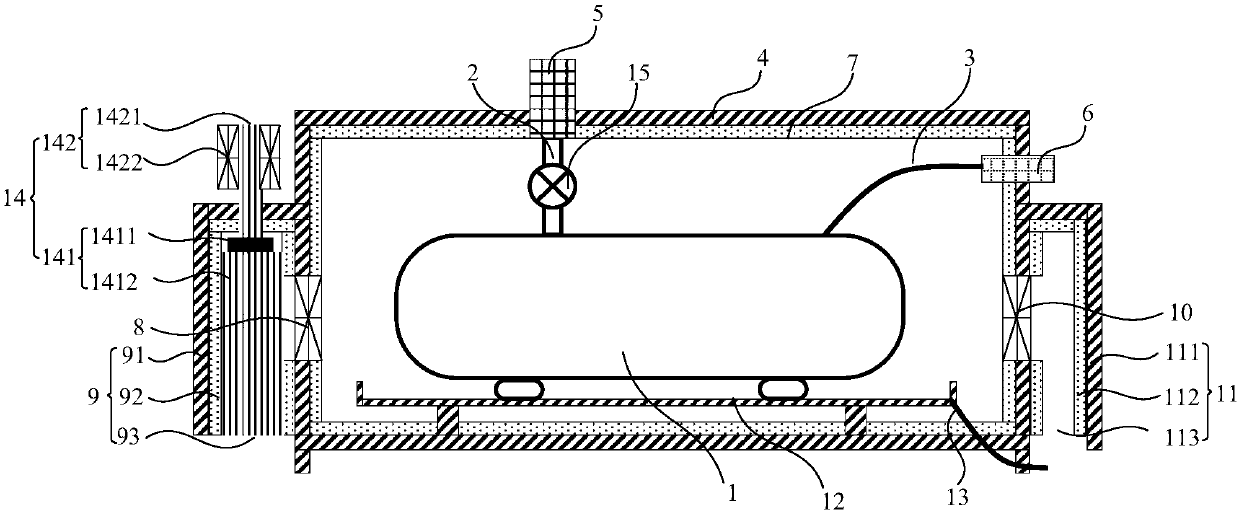

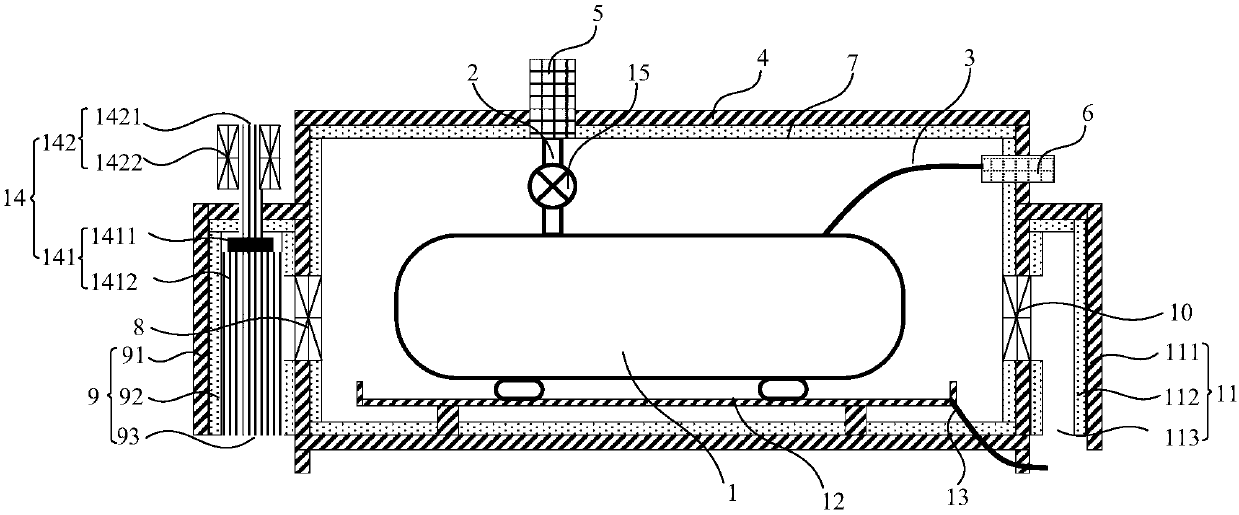

[0080] Such as figure 1 As shown, this embodiment provides a mechanical pump noise reduction device for performing noise reduction processing on the mechanical pump 1 therein, and the noise reduction device includes:

[0081] The first housing, the first housing 4 is respectively provided with an air inlet port 5 and an air outlet port 6 connected to the air inlet pipeline 2 and the air outlet pipeline 3 of the mechanical pump 1, and respectively opened on the first housing 4. an air inlet and an air outlet on two opposite side walls of the casing 4;

[0082] The first sound-absorbing foam 7 provided on the inner surface of the first shell 4;

[0083] An air inlet fan 8 installed at the air inlet;

[0084] The air inlet secondary muffler cover 9 wrapping the air inlet fan 8, wherein, the air inlet secondary muffler cover 9 is provided with an air inlet channel 93;

[0085] An air outlet fan 10 installed at the air outlet; and

[0086] The air outlet secondary muffler cover...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com