Shell component having hydraulic pressure line

A component and circuit technology, applied in the field of shell components, can solve the problems of time-intensive, complicated technology, and cost-intensive, and achieve the effect of avoiding leakage and supplementary processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

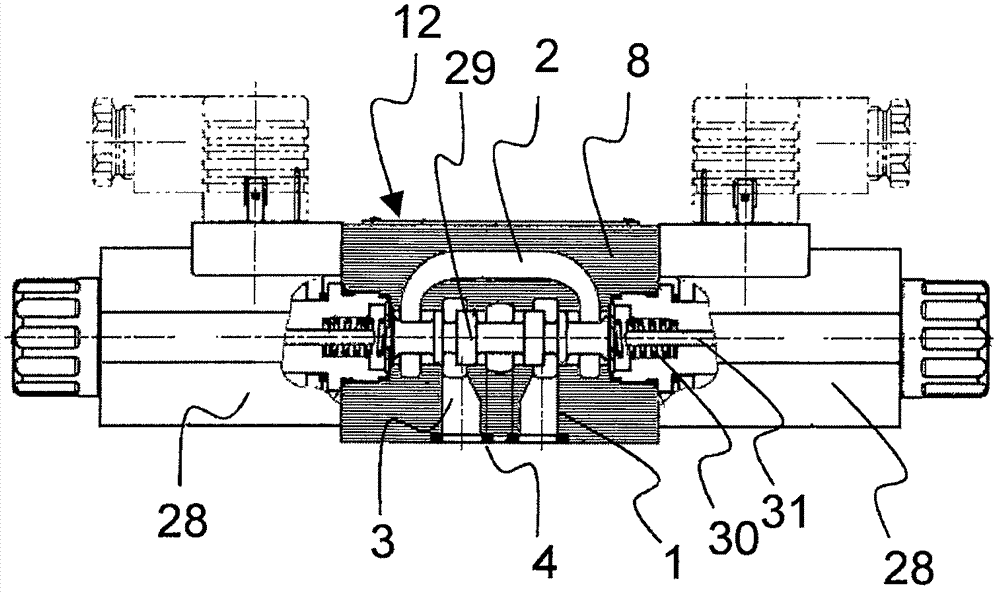

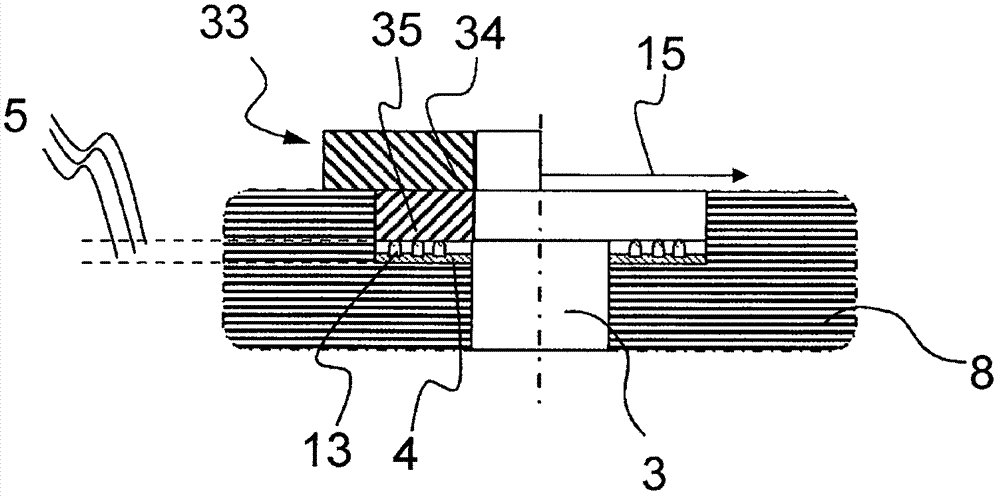

[0051] figure 1 A magnetically actuatable directional slide valve is shown by way of example for a number of other components, which may have line sections of hydraulic lines. The directional control slide valve is provided with a housing part 12 which is formed from a solid body 8 in the manner suggested here. A (possibly branched) hydraulic line 2 is formed in this housing component 12 . The hydraulic lines 2 shown here protrude from the solid body 8 at two points on the housing component 12 . There, a line section 1 is formed in each case, which has a channel 3 and a delimited sealing surface 4 surrounding said channel 3 and a space.

[0052] For the sake of illustration, the mode of operation of the magnetically actuatable directional slide valve should be briefly shown. Arranged on the sides of the housing component 12 are two magnets 28 by means of which a control slide 29 arranged centrally in the housing component 12 can be moved. The control slide 29 is moved on b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com