A tool for removing shouldered bushing of drilling jig and its use method

A technology for removing tools and bushings, which is applied in the direction of drilling molds for workpieces, manufacturing tools, hand-held tools, etc., can solve the problems of insufficient space, affecting the production progress of parts, damage, etc., and achieve the effect of improving replacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

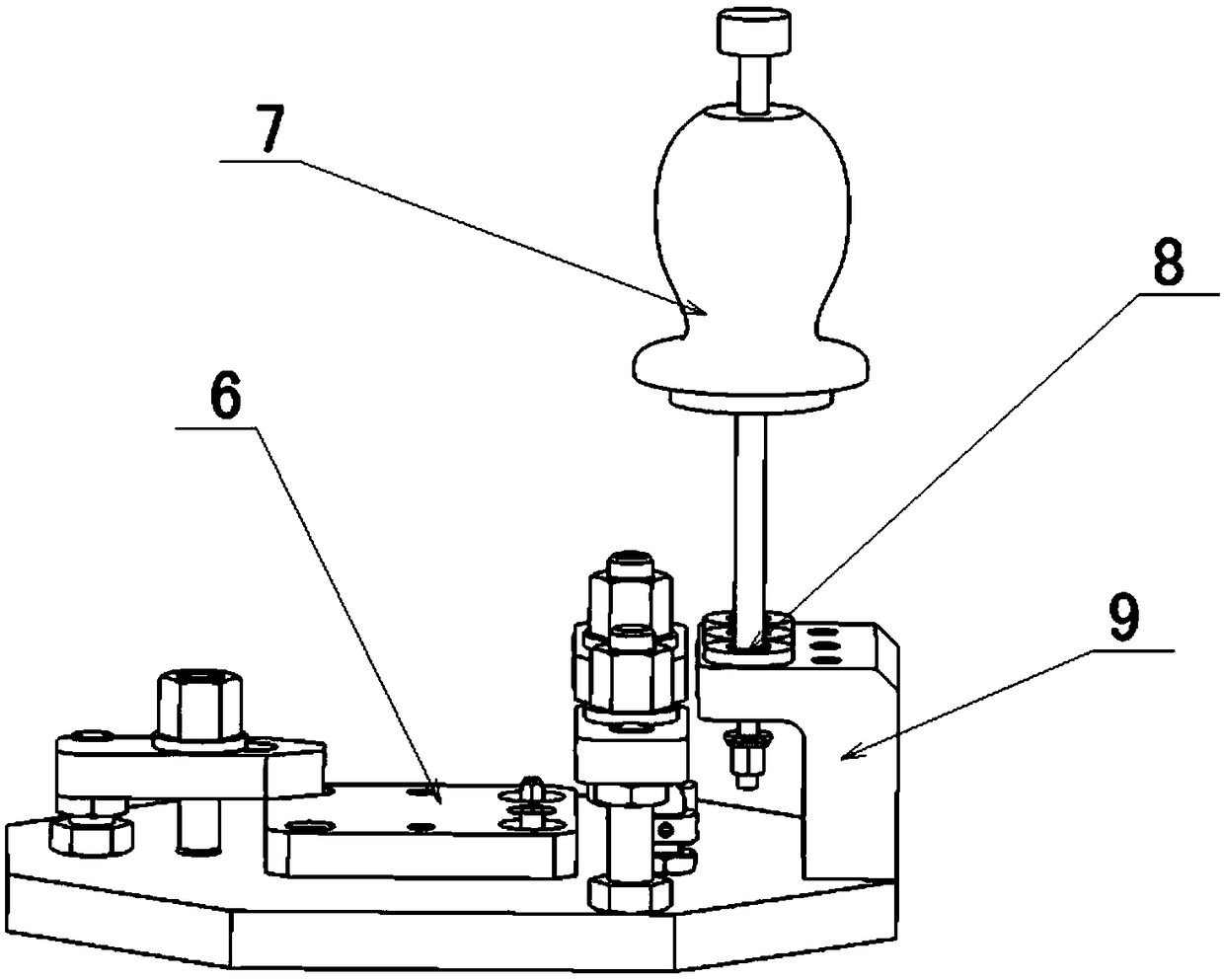

[0010] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

[0011] A method for installing a removal tool for a jig shoulder bushing, the steps are as follows:

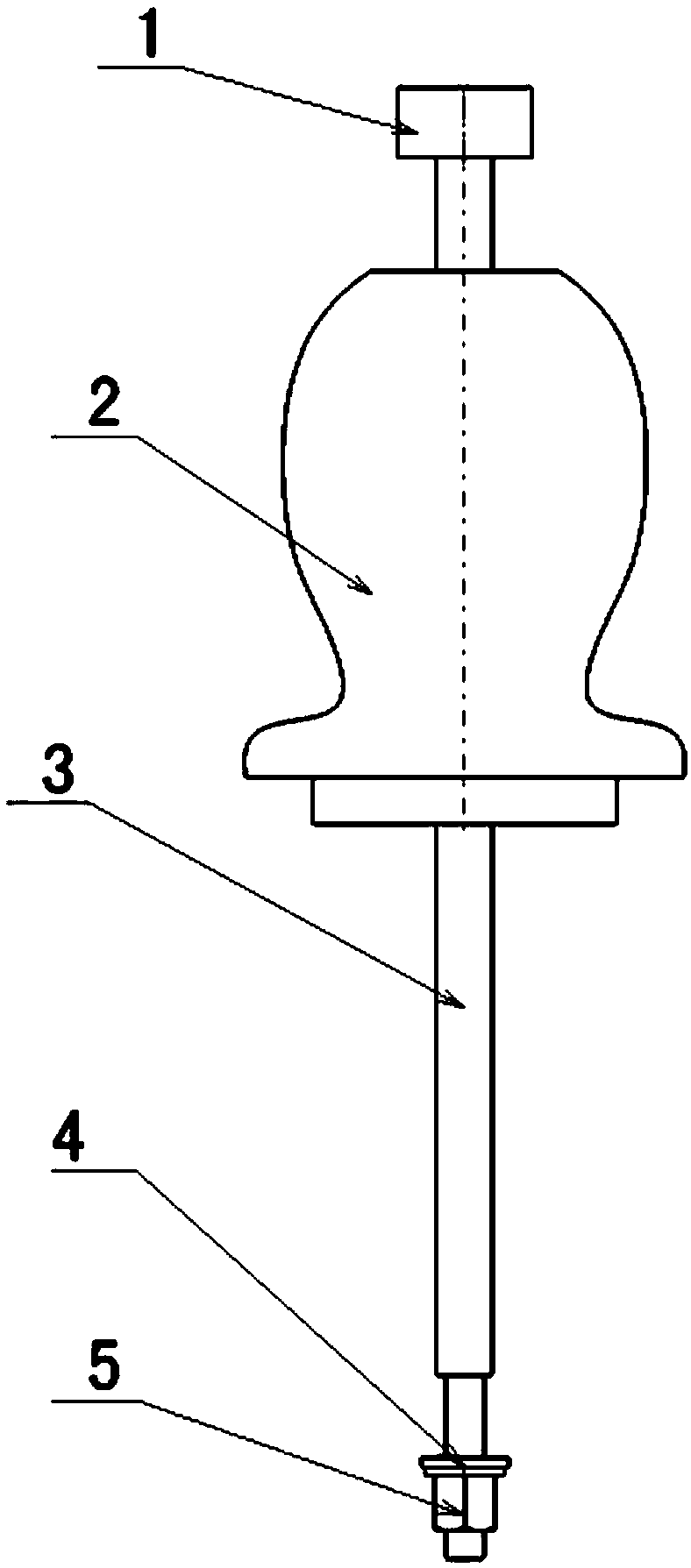

[0012] (1) The handle 2 is assembled on the main body 3, and the end stopper 1 is fixed on the end of the main body 3;

[0013] (2) The part of the lower end of the main body 3 that passes through the center hole of the bushing 8 to be removed is smaller than the inner hole of the bushing. When it is less than 5 mm from the inner hole of the bushing, it is required to add an auxiliary sleeve to realize the gap between the main body 3 and the bushing 8 to be removed;

[0014] (3) The inner hole of the adjusting gasket 4 and the main body 3 adopt clearance fit, and the outer diameter of the adjusting gasket 4 is selected to be 1-2mm smaller than the outer diameter of the bushing 8 to be removed, and the heigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com