Method for manufacturing line sections of hydraulic lines

A line and section technology, applied in the field of hydraulic blocks, can solve problems such as cost-intensive, cumbersome technology, and time-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

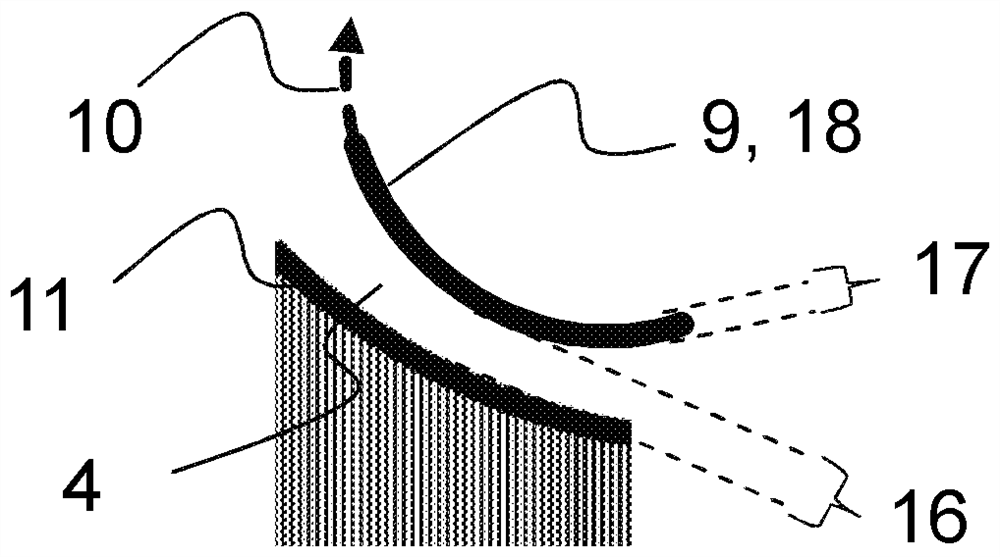

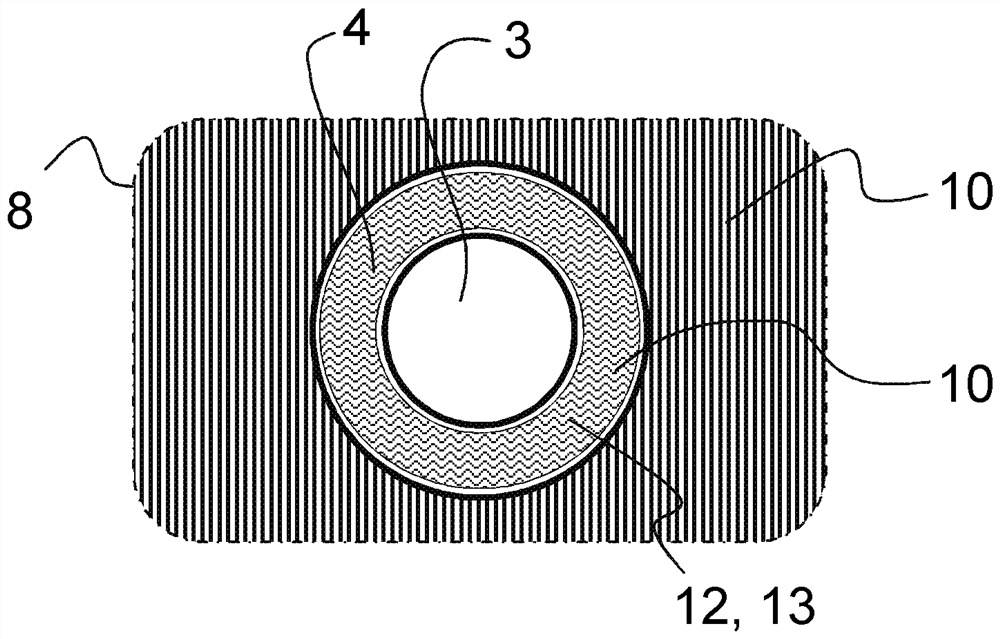

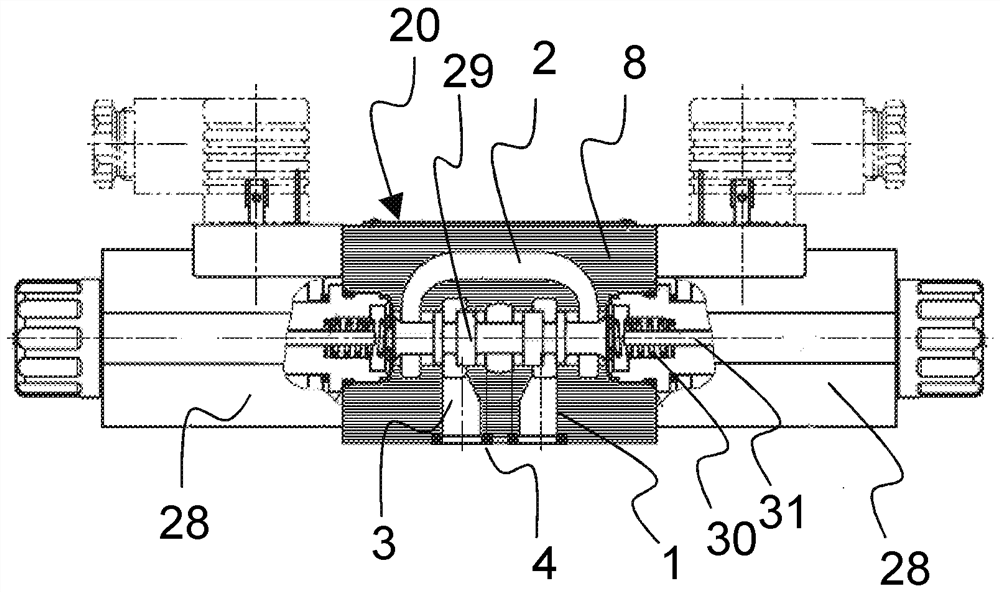

[0044] figure 1 For example, magnetically actuatable directional slide valves are shown for several further components, which can have line sections of the hydraulic line. This directional slide valve is implemented with a housing 20 formed from a solid body 8 manufactured according to the method proposed here. In said housing 20 a (possibly branched) hydraulic line 2 is formed. The hydraulic lines 2 indicated here emerge from the solid body 8 at two points of the housing 20 . There, a line section 1 is formed in each case, which has a channel 3 and a delimited sealing surface 4 surrounding said channel 3 and a space.

[0045] For the sake of illustration, the mode of operation of this magnetically actuatable directional slide valve should be briefly indicated. Two magnets 28 are arranged laterally to the housing 20 , by means of which a control slide 29 arranged in the middle of the housing 20 can be moved. The control slide 29 is moved on both sides by a tappet 31 displa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com