Method for determining effective utilization coefficient of creep distance of composite insulator

A composite insulator and creepage distance technology, applied in electrical digital data processing, CAD circuit design, special data processing applications, etc., can solve problems such as large errors in calculation results and affecting the effective utilization coefficient of creepage distances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

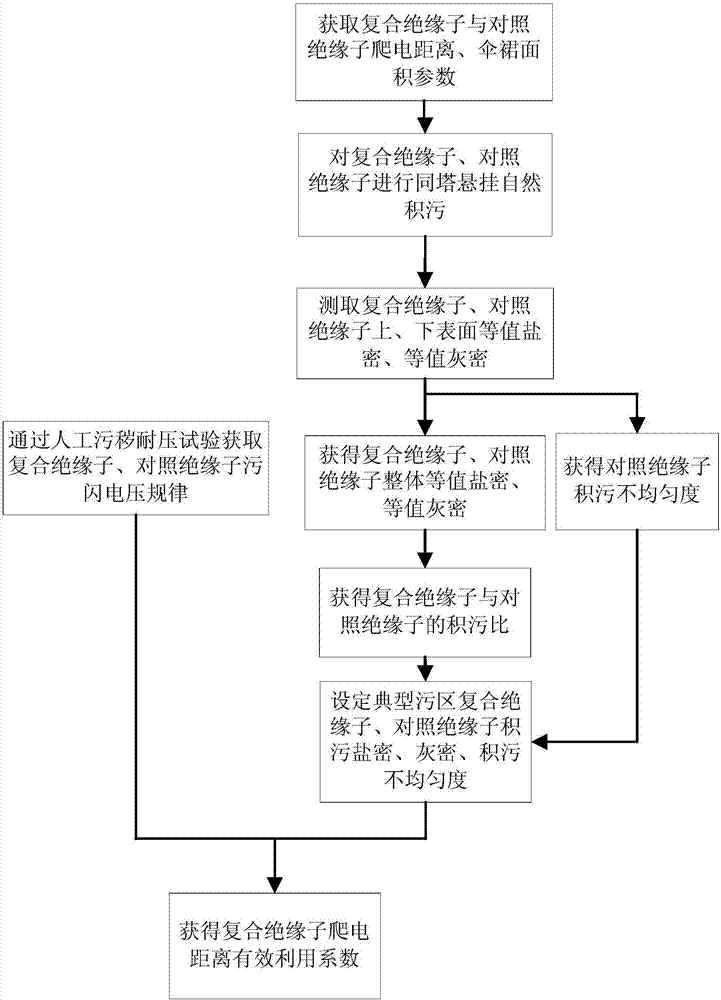

[0043] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0044] Taking the composite insulator of model FXBW-110 / 100 as an example, using XP-160 as the reference insulator, the calculation method of the present invention is used to obtain the effective utilization coefficient of the creepage distance of this type of composite insulator, and the specific steps are as follows:

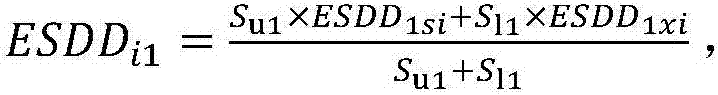

[0045] ① Obtain the creepage distance of the composite insulator, the upper surface area of the shed, and the lower surface area of the shed, which are 3200mm and 321.4cm respectively 2 、991.3cm 2 , get the creepage distance of XP-160 ceramic insulator, the upper surface area of the shed, and the lower surface area of the shed, which are 305mm and 681cm respectively 2 、891cm 2 .

[0046] ② A composite insulator and a string of XP-160 porcelain insulators were suspended on the same foundation tower for natural polluti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com