Multi-cavity braking main cylinder system with pedal feeling simulator

A technology of brake master cylinder and simulator, applied in the direction of brake, brake transmission, transportation and packaging, etc., can solve the problems of heavy workload, large fluctuation of master cylinder pressure, and insufficient directness, so as to improve the driving experience , the effect of improving the smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

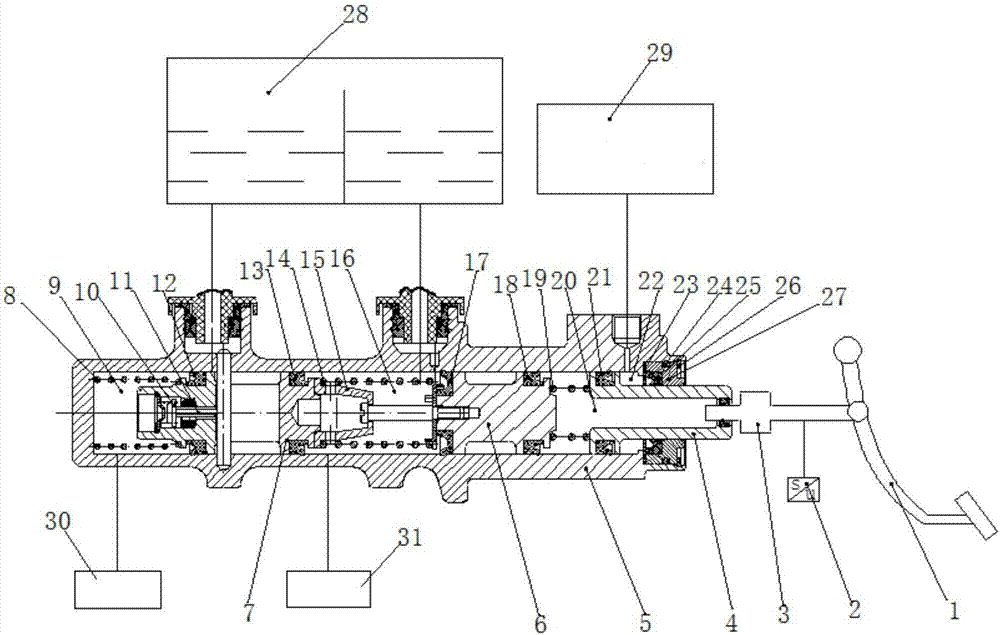

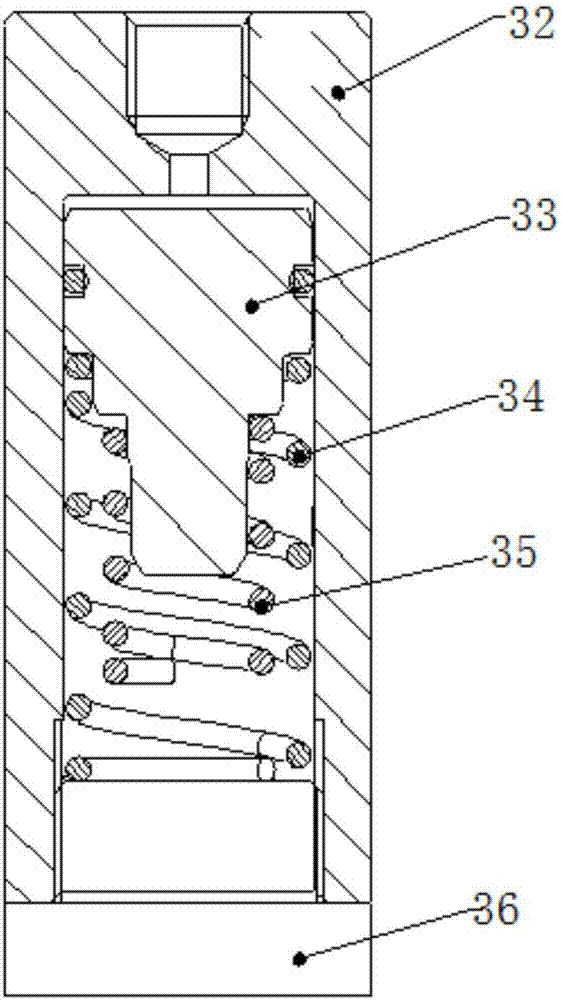

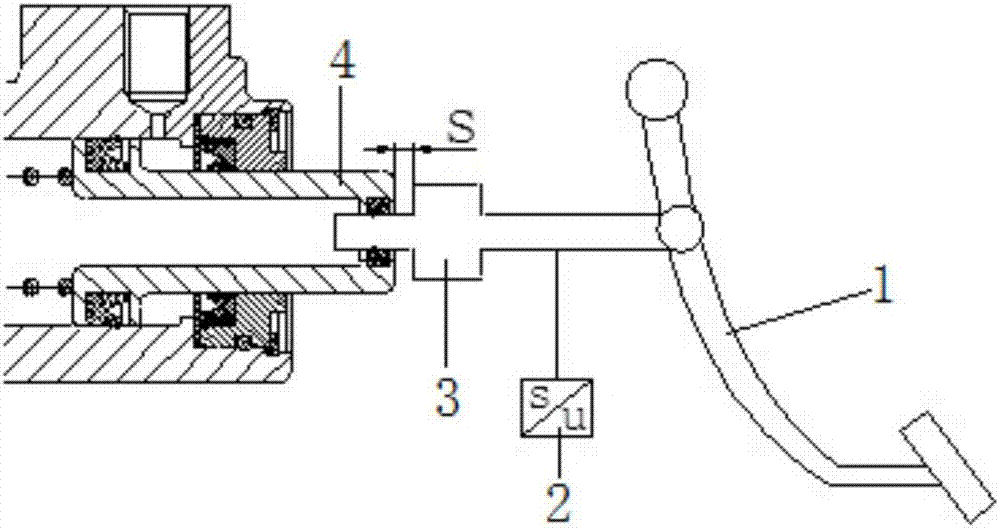

[0040] Such as figure 1 , 2, 3, the present invention provides a multi-cavity brake master cylinder system with a pedal feel simulator, including a brake pedal 1, a push rod 3, a master cylinder block 5, an oil pot 28 and a booster system 29 The master cylinder block 5 includes a T-shaped piston 4, a first piston 6, and a second piston 7; the brake pedal 1 is connected to the T-shaped piston 4 through a push rod 3, and the T-shaped piston 4 is connected to the first piston 6 The first chamber 20 is formed, the first piston 6 and the second piston 7 form the second chamber 16, the second piston 7 and the master cylinder body 5 form the third chamber 9; the T-shaped piston 4 and the master cylinder body 5 are arranged There is a baffle 23, and the baffle 23 and the T-shaped piston 4 form a pressurized chamber 22, and the described pressurized chamber 22 is connected to a pressurized system 29; the oil pot 28 is connected to the first chamber 20 and the second chamber 16 respect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com