Novel wire control brake system

A technology of brake-by-wire and control system, which is applied in the direction of brakes, brake transmissions, transportation and packaging, etc. It can solve the problems of large pressure fluctuations in the master cylinder, large workload, large fluctuations in braking force, etc., and achieve improved control Accuracy, improved driving experience, and improved ride comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

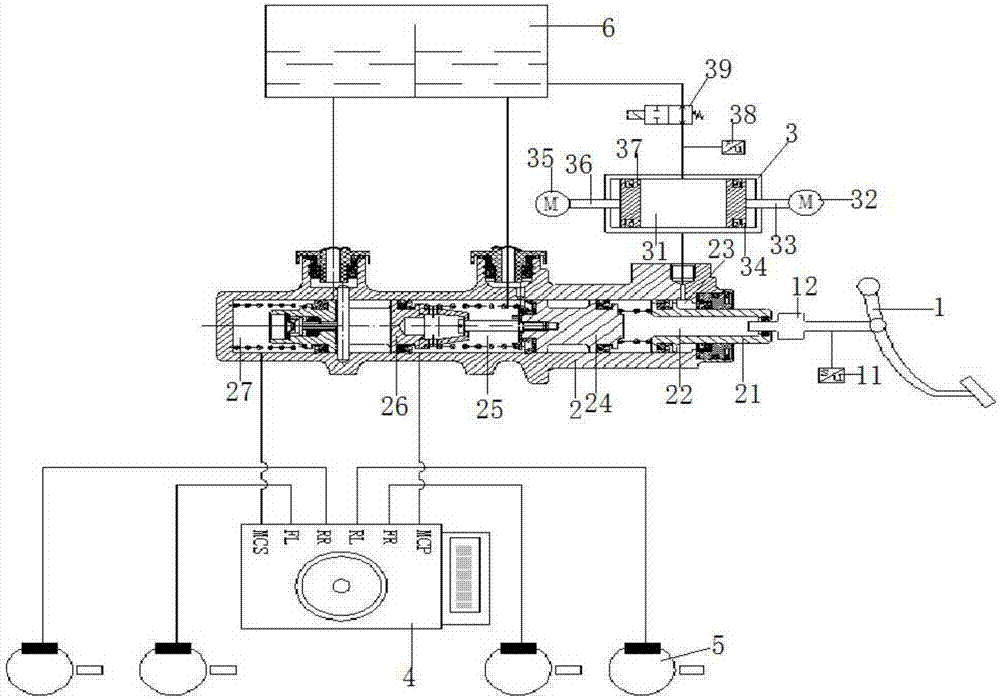

[0046] Such as figure 1 As shown, the present invention provides a novel brake-by-wire system, which includes: brake pedal 1, brake master cylinder 2, booster 3, oil pot 6, control system 4 and brake terminal 5 ;

[0047] The brake pedal 1 is connected with the brake master cylinder 2, and the brake master cylinder 2 is connected with a booster device 3 and an oil pot 6; the outlet of the brake master cylinder 2 is connected with the control system 4 and the brake terminal 5; the control system includes The ECU system and the ABS / ESP system; the brake terminal includes the braking device of the front, rear, left, and right four wheels; the supercharging device is connected with the oil pot 6 through the pressure sensor 38 and the normally open solenoid valve 39; the supercharging device includes a supercharging device Cylinder, piston and motor; Piston is arranged in booster cylinder, and motor promotes piston supercharging; Piston comprises piston one 34, piston two 37; Moto...

Embodiment 2

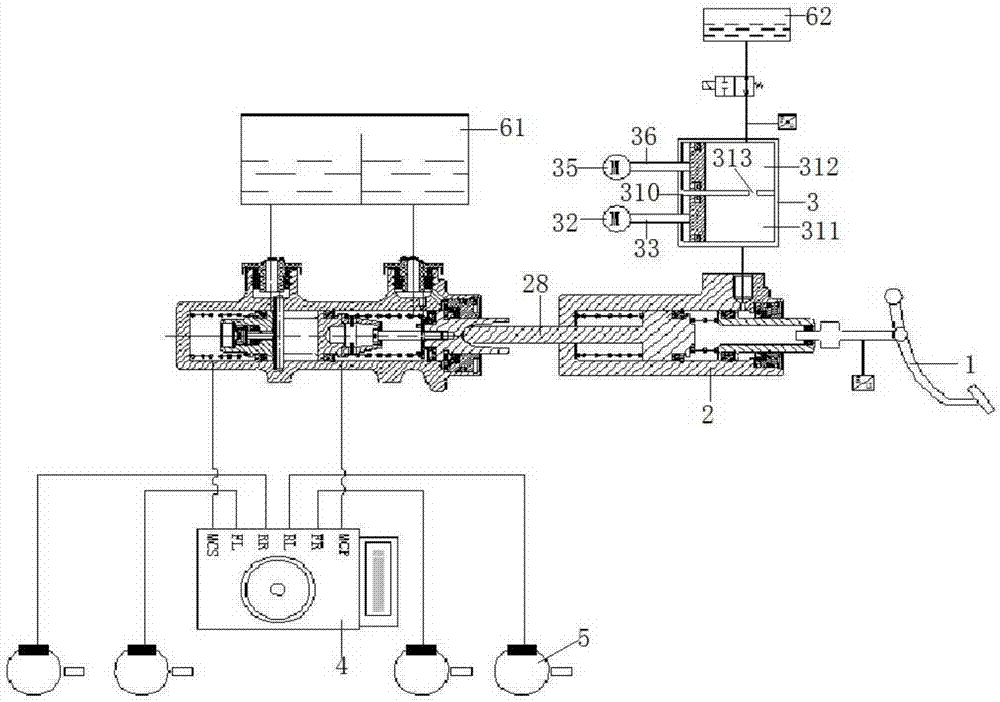

[0049] Such as figure 2 As shown, the difference between the novel linear braking system provided by this embodiment and Embodiment 1 is:

[0050] The booster cylinder is provided with a booster chamber baffle 310, and the booster chamber baffle 310 divides the booster cylinder into a first booster chamber 311 and a second booster chamber 312; the first booster chamber 311 is provided with a piston one, the described Piston 1 is connected with a self-locking screw and a high-speed, low-torque motor; piston 2 is arranged in the booster chamber 2, and the piston 2 is connected with a non-self-locking screw and a low-speed, high-torque motor; the booster chamber baffle 310 is provided with a baffle Opening 313; the brake master cylinder includes booster brake master cylinder 211 and conventional brake master cylinder 212; the T-shaped piston and the first piston are arranged in the booster brake master cylinder 211, and the second piston and the third The piston is arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com