Large-flow air-control corrugated pipe type pressure reducing valve

A bellows-type, pressure-reducing valve technology, applied to valve details, safety valves, balance valves, etc., can solve the problem of small flow rate of pressure-reducing valves, achieve the effects of small inertial force, cost reduction, and low processing accuracy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

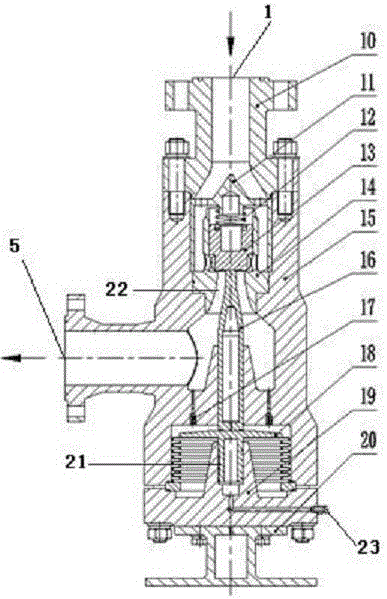

[0024] Below in conjunction with accompanying drawing, the technical scheme of the patent of the present invention is described further.

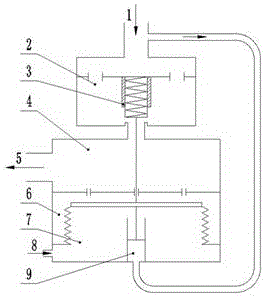

[0025] exist figure 1 Middle: High-pressure gas flows in from the high-pressure gas inlet 1, and flows out from the set gas outlet 5 after being decompressed and stabilized by the valve assembly 3. The outlet diameter is larger than the inlet diameter.

[0026] The valve body is composed of an inlet cavity 2, an outlet cavity 4, a damping cavity 6, a control cavity 7 and an unloading cavity 9. These cavities play the role of accumulating and buffering the high-pressure gas medium, and the inlet cavity 2 accumulates the high-pressure gas medium upstream of the pressure reducing valve ; The outlet cavity 4 stores the gas medium after throttling and pressure reduction; the damping cavity 6 stores the gas medium throttling through the outlet cavity, and the gas pressure of the damping cavity 6 is equal to that of the outlet cavity 4, but the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com