One-piece one-way valve with large flow rate and low starting pressure value

A technology of starting pressure and large flow, applied in the direction of control valve, valve device, functional valve type, etc., can solve the problem of low starting pressure value, the one-way valve cannot start the flow, etc., and achieve the effect of strengthening the one-way effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

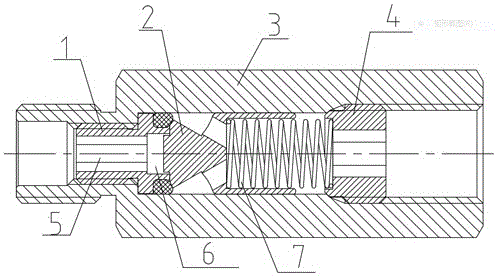

[0021] Such as figure 1 As shown, the present invention is an integrated one-way valve with a large flow rate and low starting pressure value, including a valve body 3, which is characterized in that the valve body 3 is radially symmetrical with respect to the liquid flow direction, and a cavity is arranged inside the valve body 3. According to the flow direction of the liquid, there are valve head 1, liquid inlet hole 5, pressure chamber 6, switch device 2, spring 7, and valve seat 4 in sequence in the cavity. The liquid inlet hole 5 is radially located inside the valve head 1, and the valve head 1 is tightly Attached to the inner wall side of the valve body 3, one end of the pressure chamber 6 is connected with the liquid inlet hole 5, and the other end is pressed against the switch device 2, one end of the spring 6 is pressed against the switch device 2, and the other end is pressed against the valve seat 4, and the outlet hole diameter Located inside the valve seat 4, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com