Shutters blade fixing structure

A technology for fixing structures and shutters, applied in the field of shutters, can solve the problems of large volume of blades, inconvenient assembly by staff, and delay in assembly completion time, and achieve the effect of preventing detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

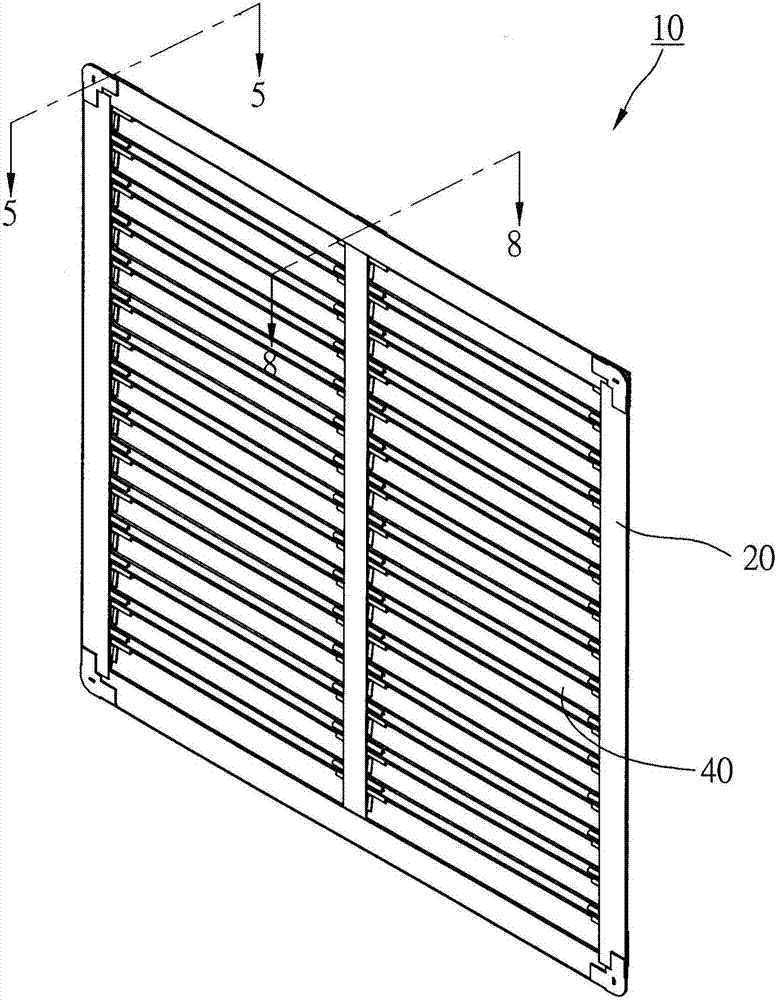

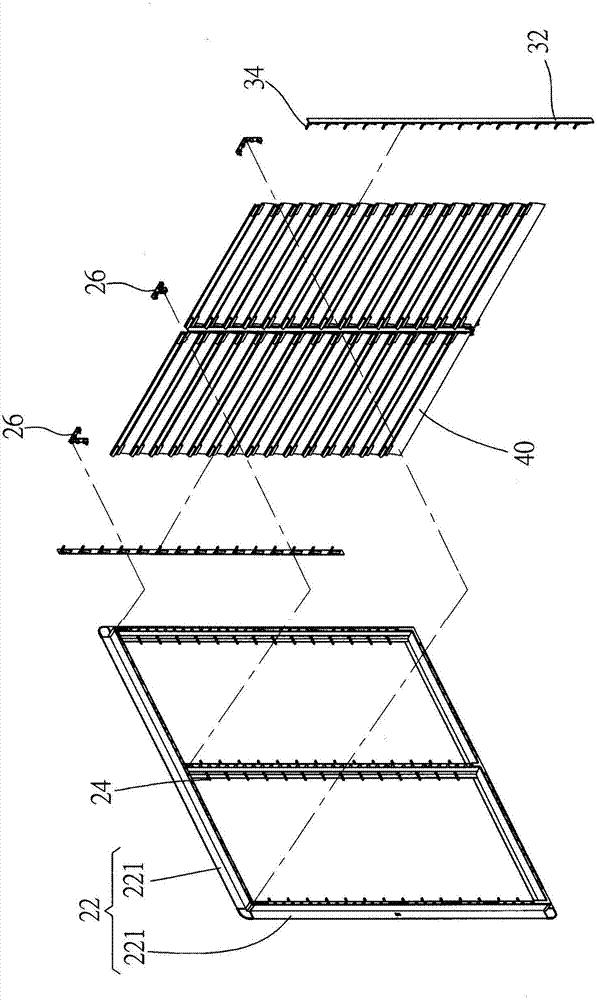

[0020] Please refer figure 1 , figure 2 , Figure 7 as well as Figure 8 As shown, the shutter 10 includes a fixed structure using a preferred embodiment of the present invention. The fixed structure includes a window frame 20, a linkage group, and a plurality of blades 40.

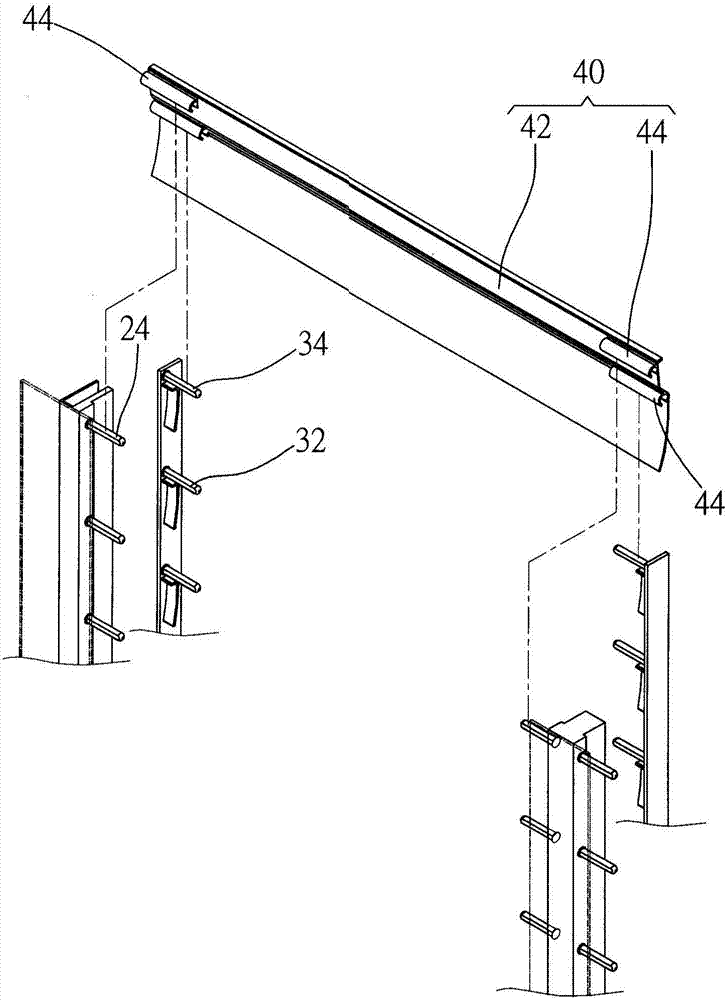

[0021] The window frame 20 includes a frame 22, a plurality of first pivots 24, and a plurality of connecting members 26; wherein the frame 22 includes a plurality of frame bars 221, and a plurality of perforations are recessed on the side of each frame bar 221 222, each of the through holes 222 is a tapered hole; each of the connecting members 26 includes at least two protrusions 261. In this embodiment, the number of protrusions is three, and each of the protrusions 261 has a tapered section 261a; The tapered section 261a of the protruding column 261 respectively penetrates the perforation 222 of the frame strip 221, thereby achieving the effect of combining the frame strip 221 in a tight fitting manner. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com