Dental restoration molding techniques

A technology of dental prosthetics and prosthetics, applied in the field of dental prosthetics, can solve problems such as tooth allergies, return visits, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

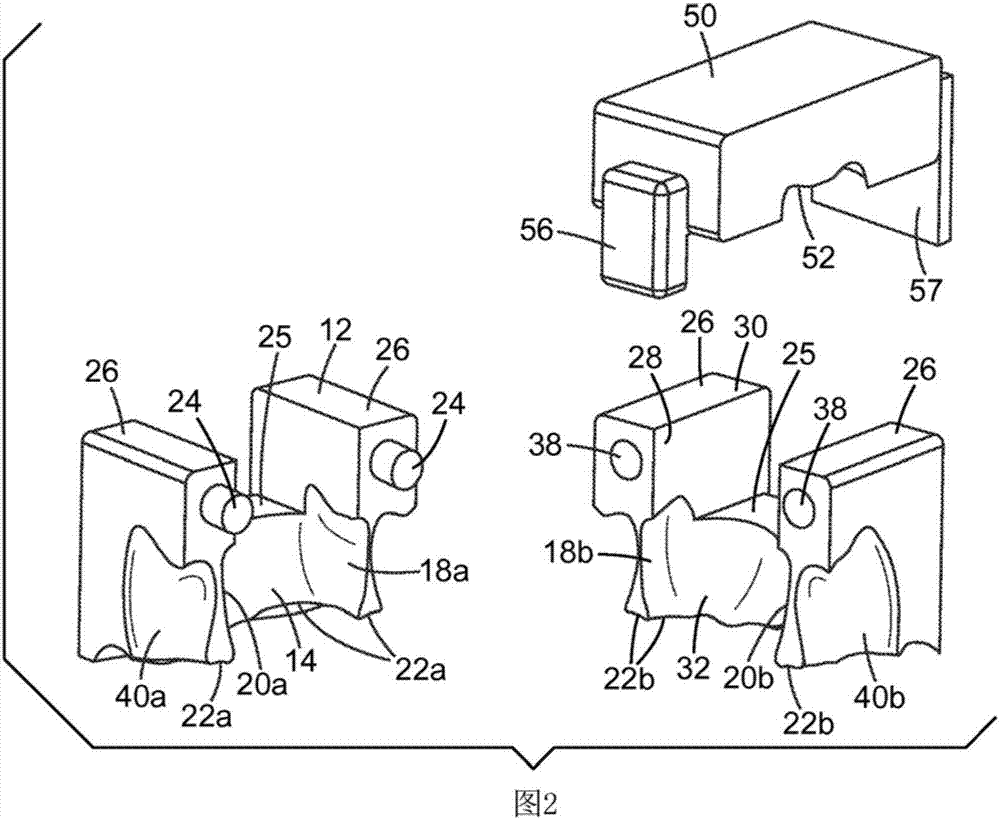

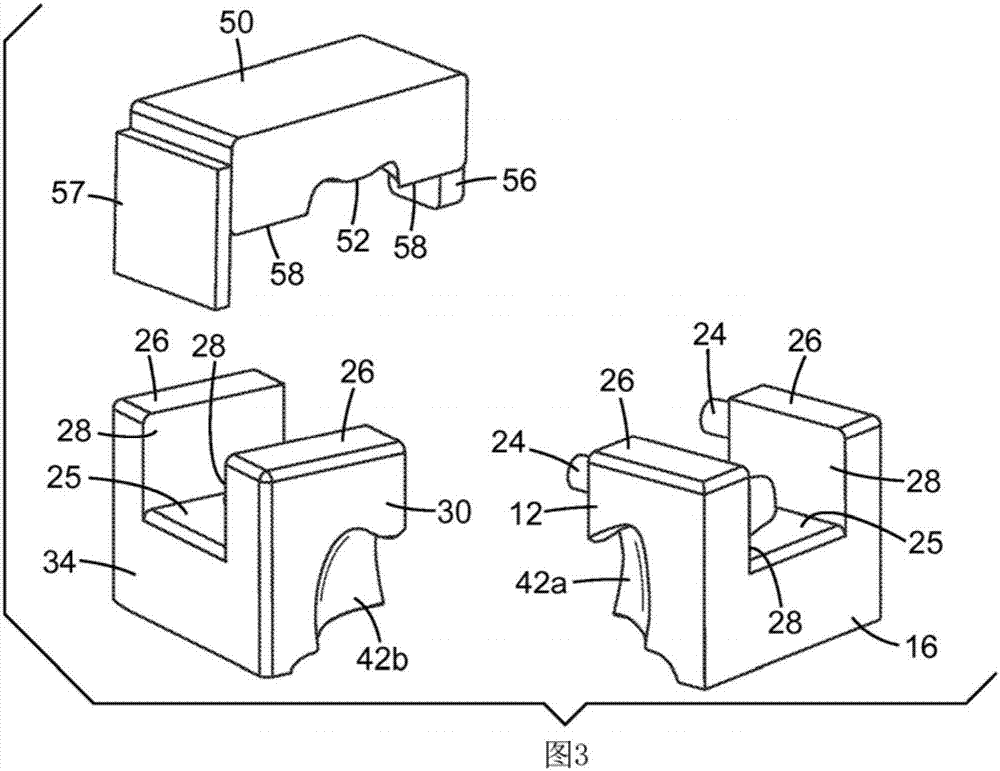

[0021] While conventional dental restorative techniques typically involve iterative steps and benefit from significant practitioner skill and experience, the present disclosure includes that custom molds can be utilized to facilitate the use of conventional dental restorative techniques more accurately and faster than is generally possible in a patient's A technique for forming dental restorations in the mouth.

[0022] The technique disclosed herein involves capturing a patient's dentition in three dimensions with an intraoral scanner. Custom tools for dental restorations may include molds based on the patient's three-dimensional (3D) dentition. The techniques disclosed herein can facilitate high quality dental restorations with reduced time and skill requirements compared to conventional dental restoration techniques.

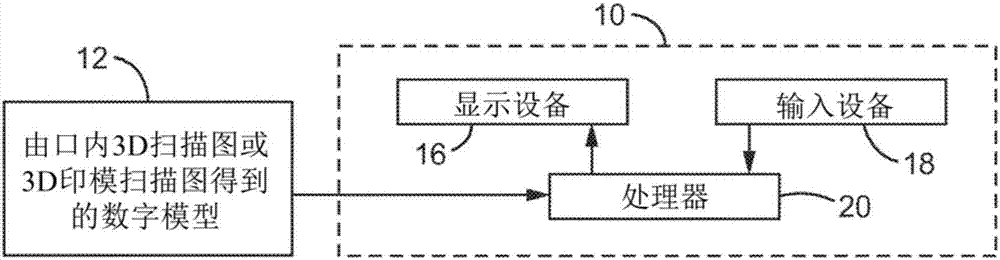

[0023] figure 1 is a diagram of a system 10 for detecting and defining tooth structures using digital 3D models based on intraoral 3D scans, or impression...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com