Conveying assembly capable of achieving efficient cleaning

A component and high-efficiency technology, applied in cleaning methods and utensils, cleaning methods using gas flow, chemical instruments and methods, etc., can solve problems such as large detection errors and affect product detection results, and achieve good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

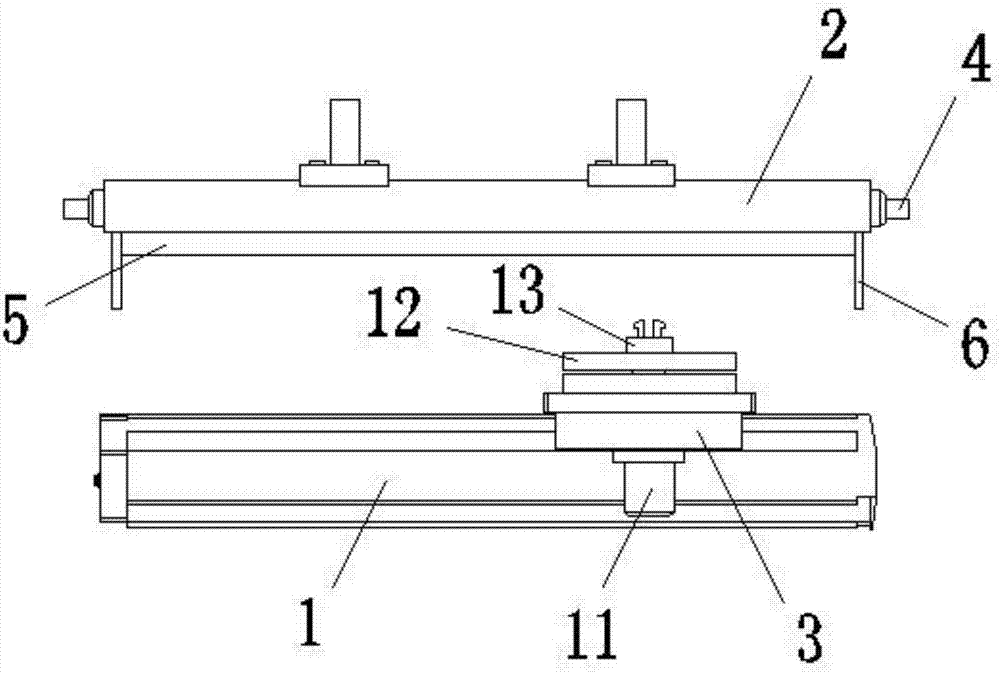

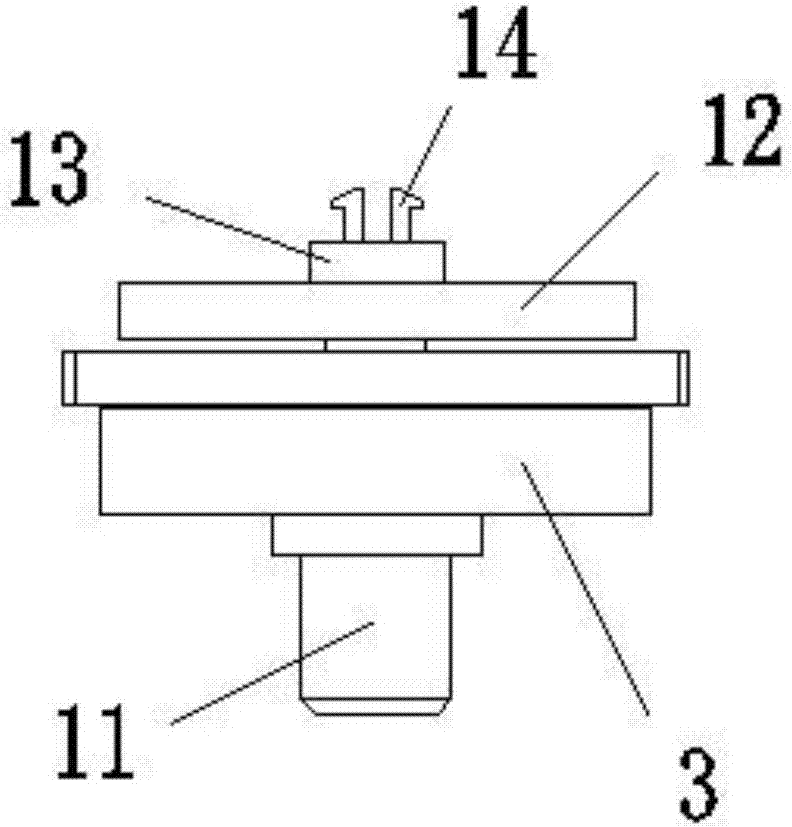

[0012] The present invention is described below in conjunction with accompanying drawing.

[0013] as attached Figure 1-2 As shown, a high-efficiency cleaning and conveying assembly described in the present invention includes a traversing device 1 and a cleaning frame 2 erected on the upper side of the traversing device 1; the traversing device 1 is provided with a mobile platform 3, A motor 11 and a turntable 12 are arranged on the top, the motor 11 is arranged on the lower side of the mobile platform, the turntable 12 is driven by the motor 11, a matching ring 13 is arranged on the turntable 12, and a plurality of centrifugal clamping arms 14 are arranged on the matching ring 13 The bottom of the centrifugal card arm 14 and the matching ring 13 are provided with a reset elastic member; the cleaning frame 2 is provided with an air inlet 4 and an air outlet row 5, and the air inlet 4 is arranged on the front and rear ends of the cleaning frame 2, The air inlet 4 communicates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com