Double-layer cover automatic riveting machine

A technology of riveting machine and cover body, which is applied in the direction of conveyor objects, loading/unloading, transportation and packaging, etc. It can solve the problems of reducing work efficiency, breaking semi-finished products, ejecting to the outside of the equipment, and even staff, etc., to improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

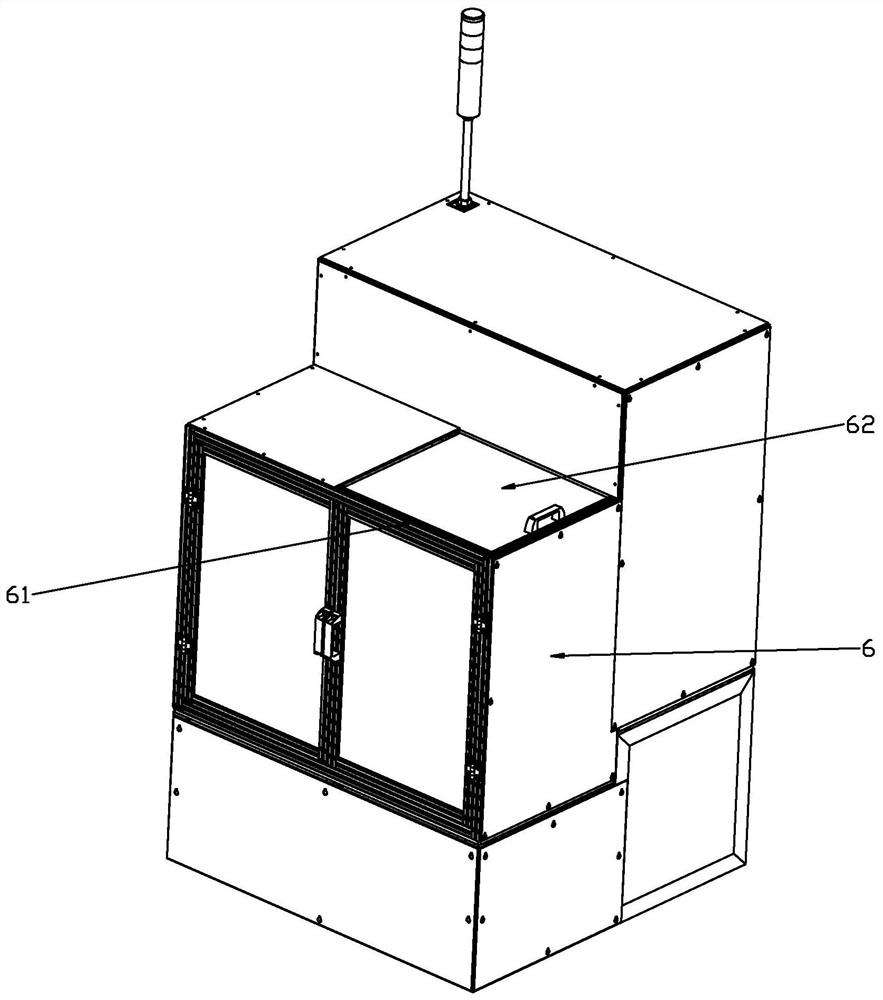

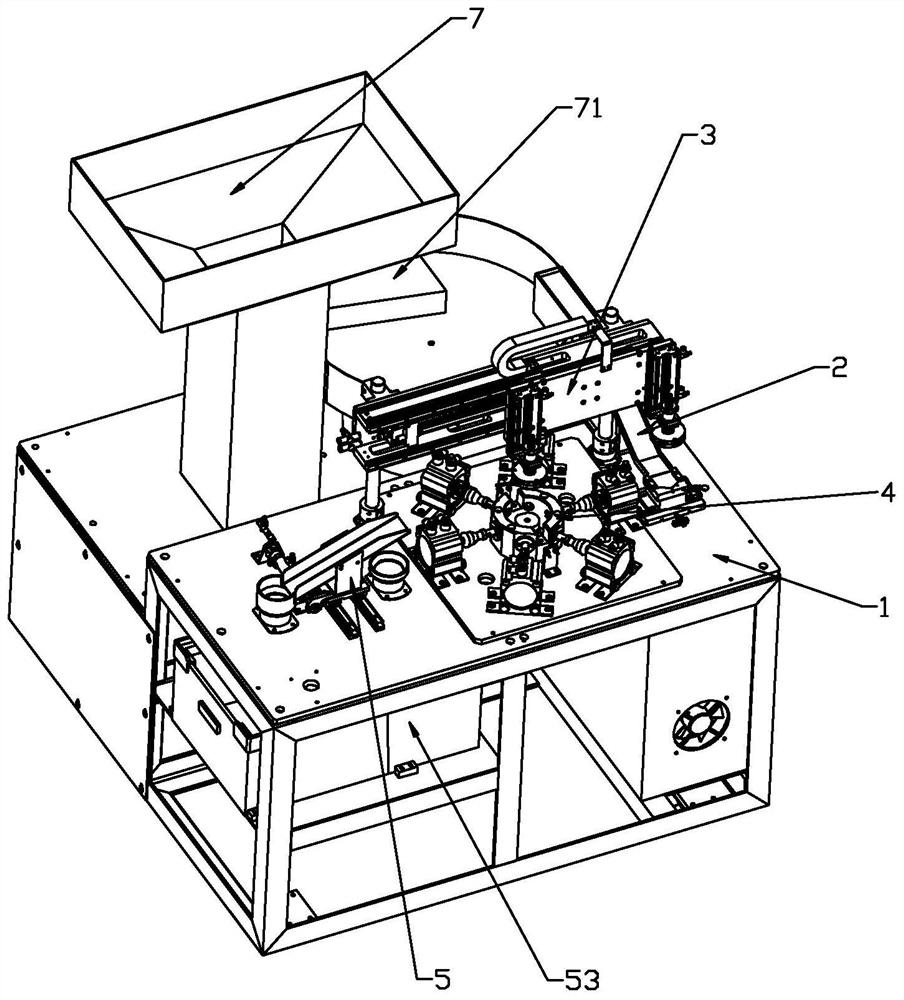

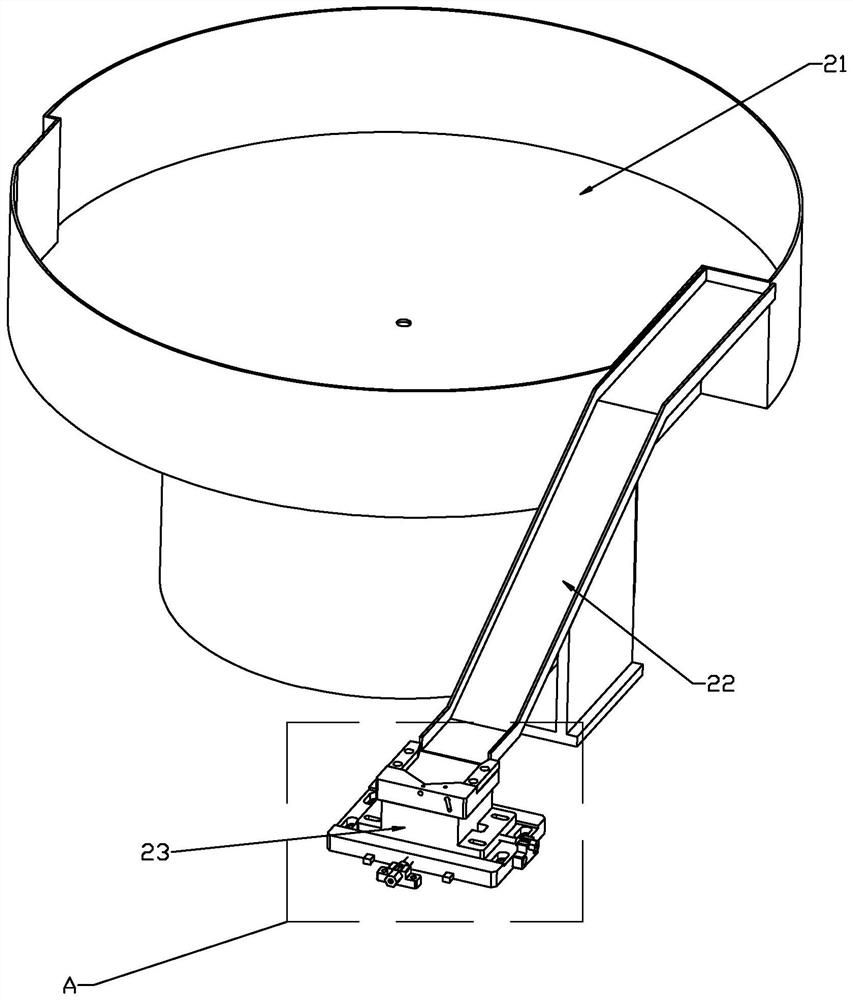

[0035] like figure 1 — Figure 11 As shown, the present invention discloses a double-layer cover automatic riveting machine, which includes a processing table 1, and a feeding device 2, a material transporting device 3, a riveting device 4 and a receiving device 5 are arranged on the processing table 1. The feeding device 2 includes a vibrating plate 21, a feeding track 22 and a reclaiming seat 23. The feeding track 22 connects the discharge port of the vibrating plate 21 with the feeding seat 23, and the feeding track 22 gradually moves away from the height of the vibrating plate 21. Lowering, the upper end face of the reclaimer seat 23 is provided with a reclaimer chute 231 for placing a single double-layer cover, the reclaimer chute 231 is provided with an inlet 232 connected with the feeding track 22, and the reclaimer seat 23 is located on both sides of the inlet 232 respectively The side positioning blocks 233 are detachably provided. The side positioning blocks 233 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com