A device for coating the surface of medicine granules for children

A coating device and a technology for children's medication, which is applied in the direction of making drugs into special physical or ingestible devices, coatings, etc., can solve the problems of children's refusal, delay in treatment, difficulty in taking, etc., and reduce the chance of refusing to take medicine , the effect of reducing stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

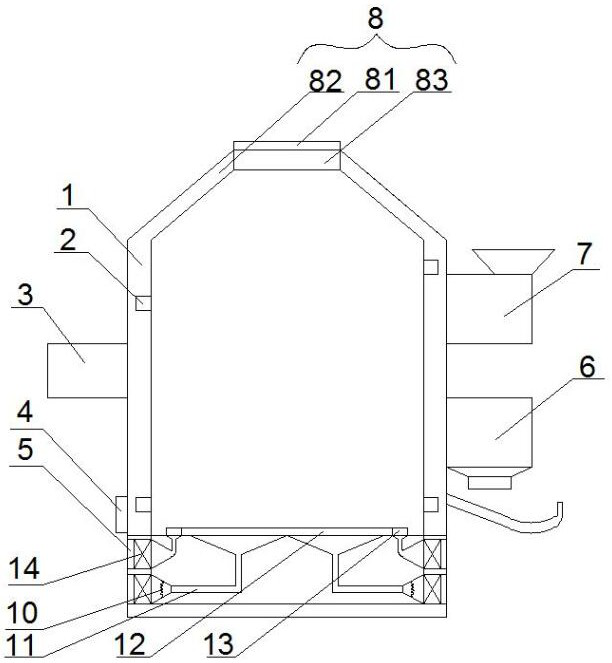

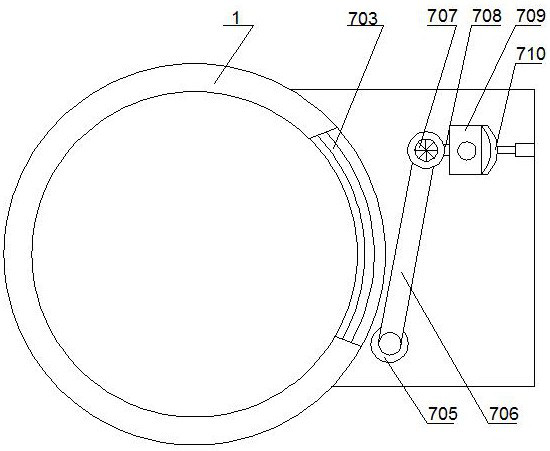

[0051] A device for coating the surface of medicine granules for children, comprising a housing 1, an air suspension mechanism arranged at the bottom of the housing 1, an air suspension mechanism arranged on the upper part of the air suspension mechanism and positioned on the housing for placing medicine granules The feeding mechanism 7 is arranged on the upper part of the air suspension mechanism and is located on the housing 1. The spraying mechanism 3 is used to smear the coating material on the medicine particles. Mechanism 8, which is arranged on the housing 1 and is used to unload the unloading mechanism 6 after the application is completed, and is used to coordinate and control the air suspension mechanism, feeding mechanism, spraying mechanism, air outlet mechanism and unloading mechanism the control agency;

[0052] The air suspension mechanism includes an air suspension disk arranged on the bottom surface of the housing 1 and composed of a plurality of air injection ...

Embodiment 2

[0065] The difference from Embodiment 1 is that a funnel-shaped surrounding wall is provided at the connection between the air inlet pipe 11 and the air inlet hole.

[0066] The air suspension disk is a circular disk, and forty air injection units 121 are formed along multiple diameters and concentric circles.

[0067] The end of the discharge rod is provided with a downward concave inner wall for carrying medicine particles.

[0068] The air outlet mechanism 8 includes a safety cover 82 arranged at the top of the housing, an air outlet pipe 83 arranged on the safety cover 82 , and a filter screen 81 arranged at the air outlet pipe 83 .

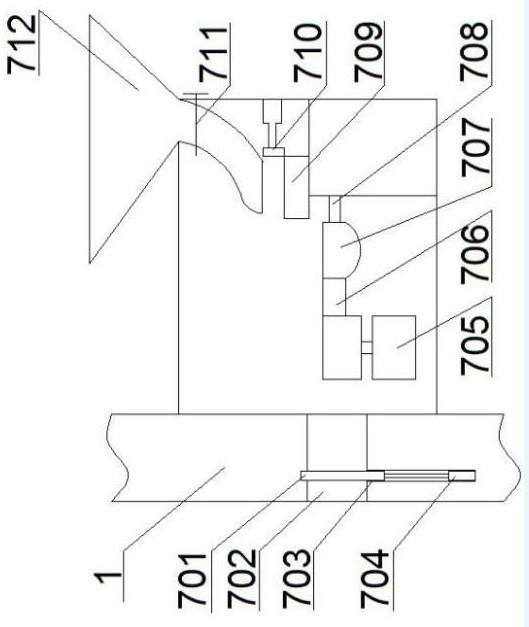

[0069] The outer side of the loading slot is located at the lower part of the weighing module 709 and is used to trigger the loading push switch 708 of the pushing module 710 and the loading switch unit.

Embodiment 3

[0071] The difference from Embodiment 1 is that: the air inlet pipe 12 is located inside the fan 14 and is provided with a heating wire 10 for heating.

[0072] The airflow can be heated by the electric heating wire, and then the drying of the smearing material can be realized, so as to speed up the drying of the smearing and wrapping material, and speed up the processing speed of the device for the medicine particles.

[0073] Embodiment Three

[0074] The difference from any one of the first to third embodiments is that: the upper part of the feeding tube is provided with a feeding funnel 610 for collecting the medicine particles.

[0075] An electromagnetic valve 711 for controlling feeding is provided on the material pipe between the storage bin 712 and the weighing module 709 .

[0076] In this embodiment, the solenoid valve is used to ensure that one medicine granule falls onto the weighing module each time, and only after the pushing module pushes the medicine granules...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com