Weaving bar preventing method of loom and apparatus for the same

A weaving machine and rung technology, which is applied in the field of rung prevention, can solve problems such as only considering the amount of recoil and cannot be effectively prevented, and achieve the effect of preventing rungs from appearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0084] Hereinafter, an embodiment of the rung preventing device for a loom according to the present invention will be described based on the drawings.

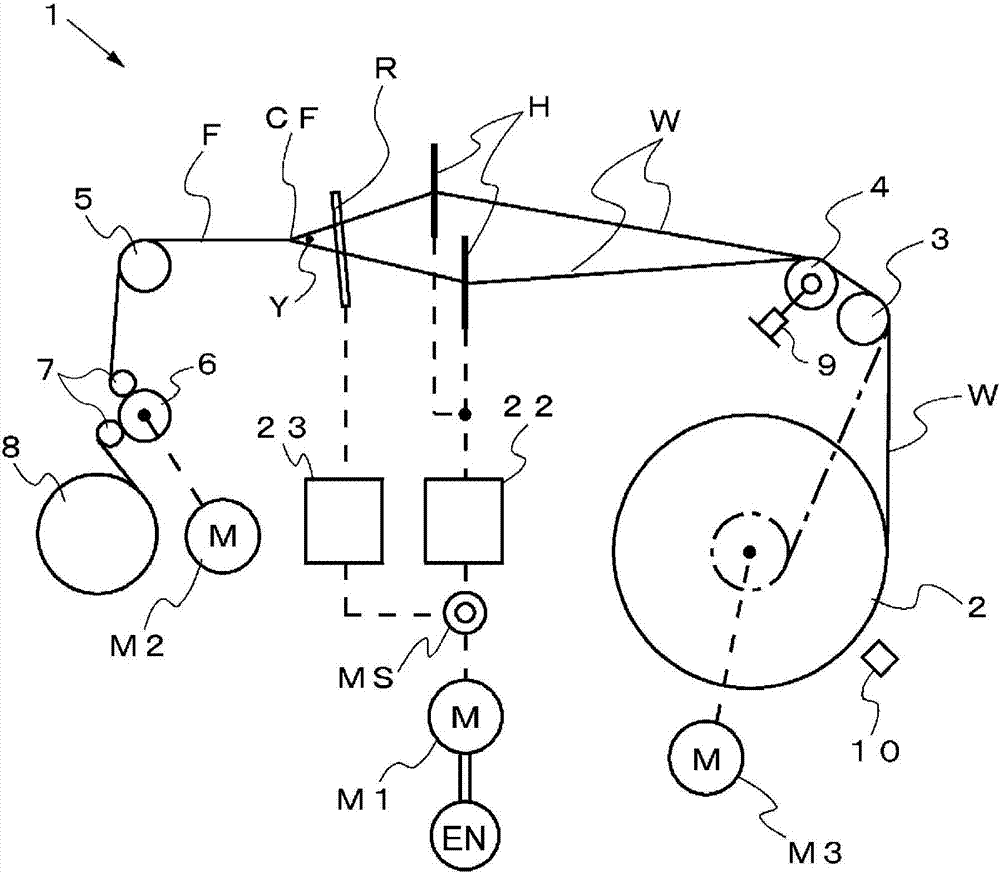

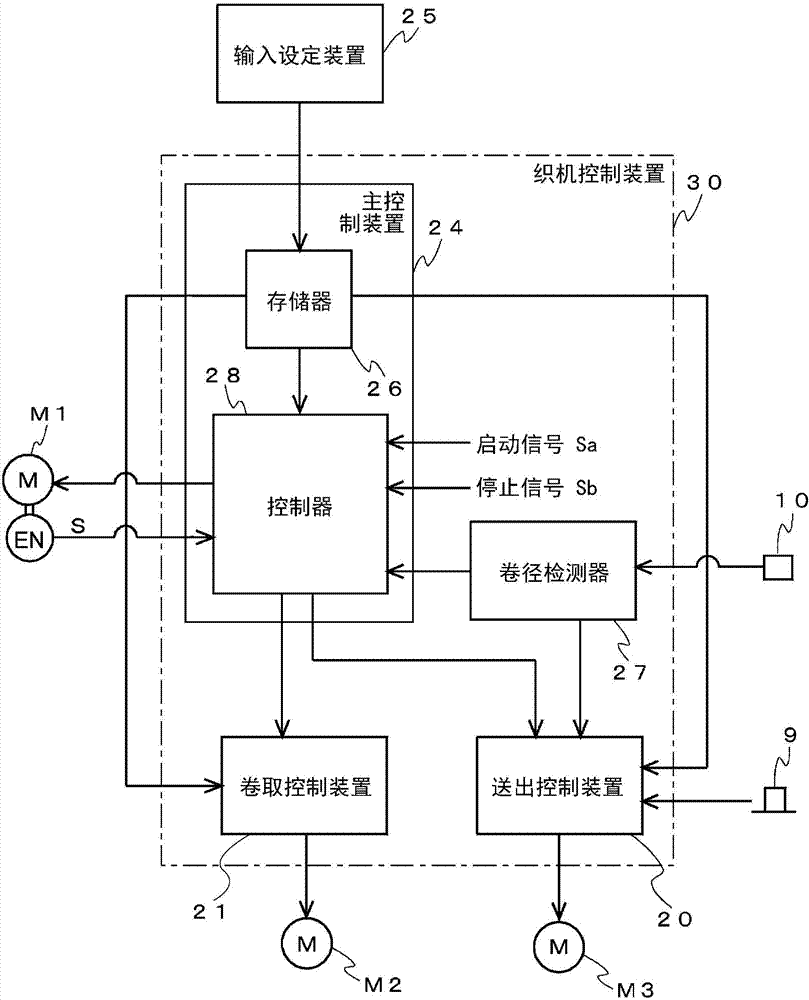

[0085] figure 1 An example of a loom (for example, an air jet loom) to which the rung preventing device of the present invention is applied is shown. In the loom 1, the warp yarn W sent out in sheet form from the warp beam 2 is wound and guided by the guide roller 3 and the tension roller 4, and then guided to the cloth fell CF via the heald H and the reed R. In addition, the warp yarn W is given a shedding motion by the vertical movement of the corresponding heald H, and a shedding is formed in a predetermined period within one weaving cycle. Then, the weft yarn Y is inserted into the opening formed by the warp yarn W by a weft insertion device (not shown), and the weft yarn Y is driven into the fell CF by the reed R, thereby weaving the woven fabric F. In addition, the woven fabric F woven in this way is wound and guided b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com