Press for large size products

A product and equipment technology, applied in the field of industrial pressing equipment for large-sized products, which can solve the problems of difficult disposal of production waste or debris, no tension/structural state, resistance to influence product stress, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

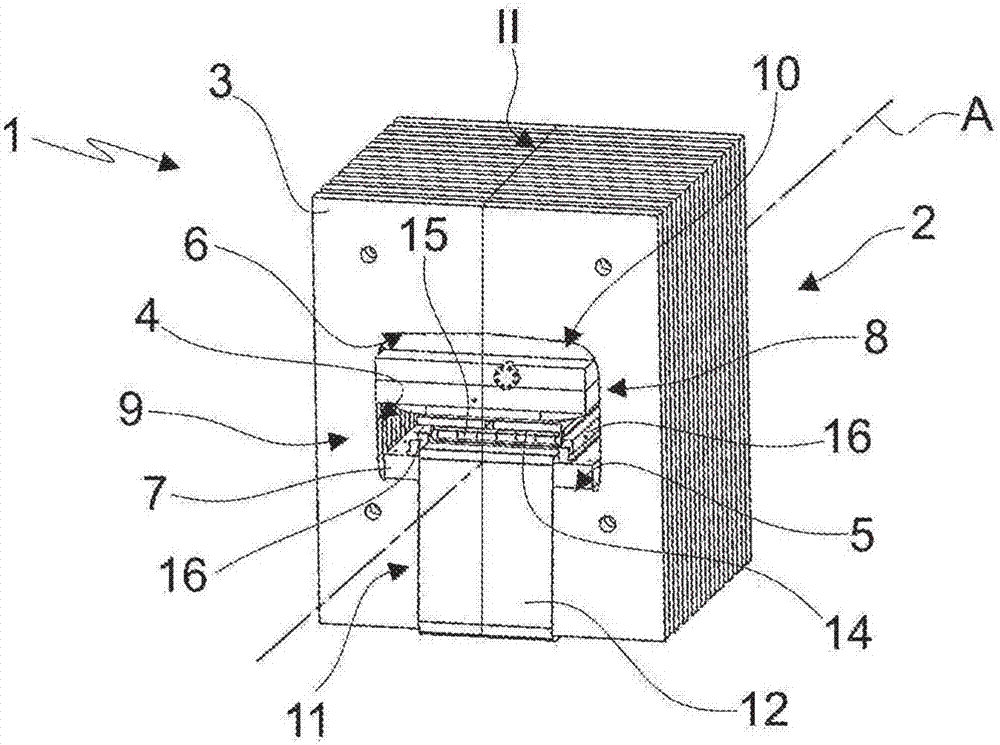

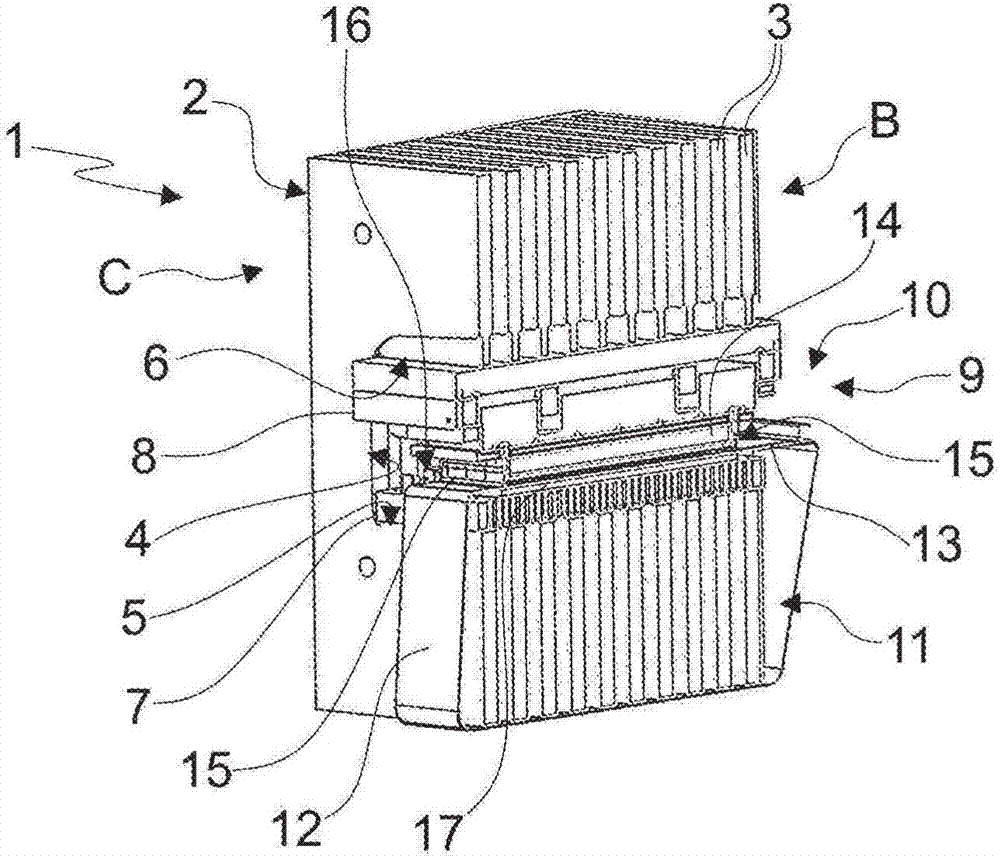

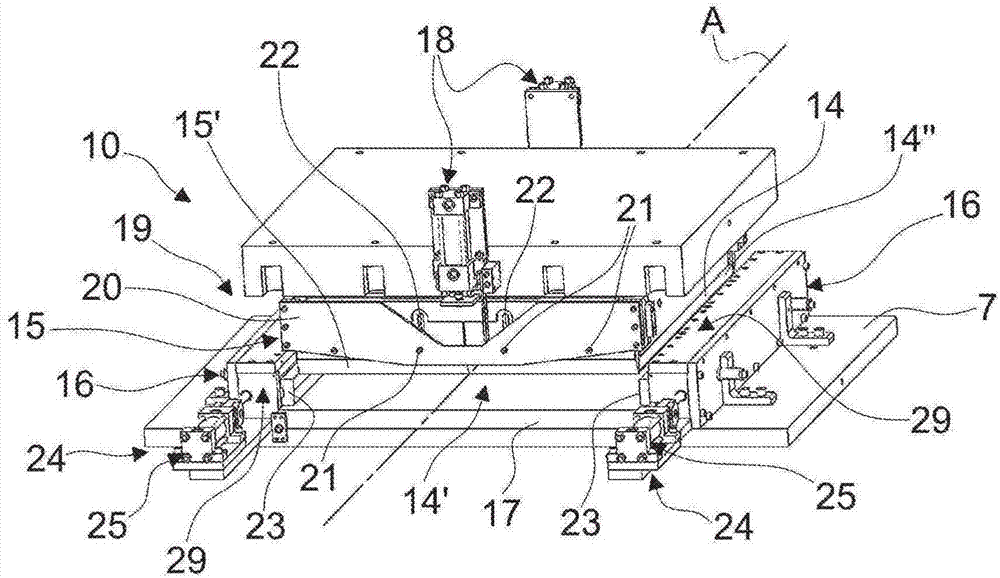

[0026] Referring to the accompanying drawings, an industrial pressing plant for large-sized ceramic products according to the present invention is indicated generally by reference numeral 1 .

[0027] Preferably, the pressing device 1 according to the invention is arranged for pressing materials made of powder as desired to obtain ceramic products such as tiles, plates or the like.

[0028] According to one version of the invention, the material to be compacted is selected from common ceramic powders.

[0029] It should be understood that the powdered ceramic material to be pressed can be mixed with other substances according to specific needs if necessary, and this does not limit the purpose of the present invention.

[0030] The pressing device 1 according to the invention has a non-welded or possibly welded modular structure 2 comprising a plurality of annular plates 3 arranged in continuous alignment one after the other.

[0031] According to another version of the invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com