Patents

Literature

39 results about "Dimension Product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The result or product of multiplying dimensions.

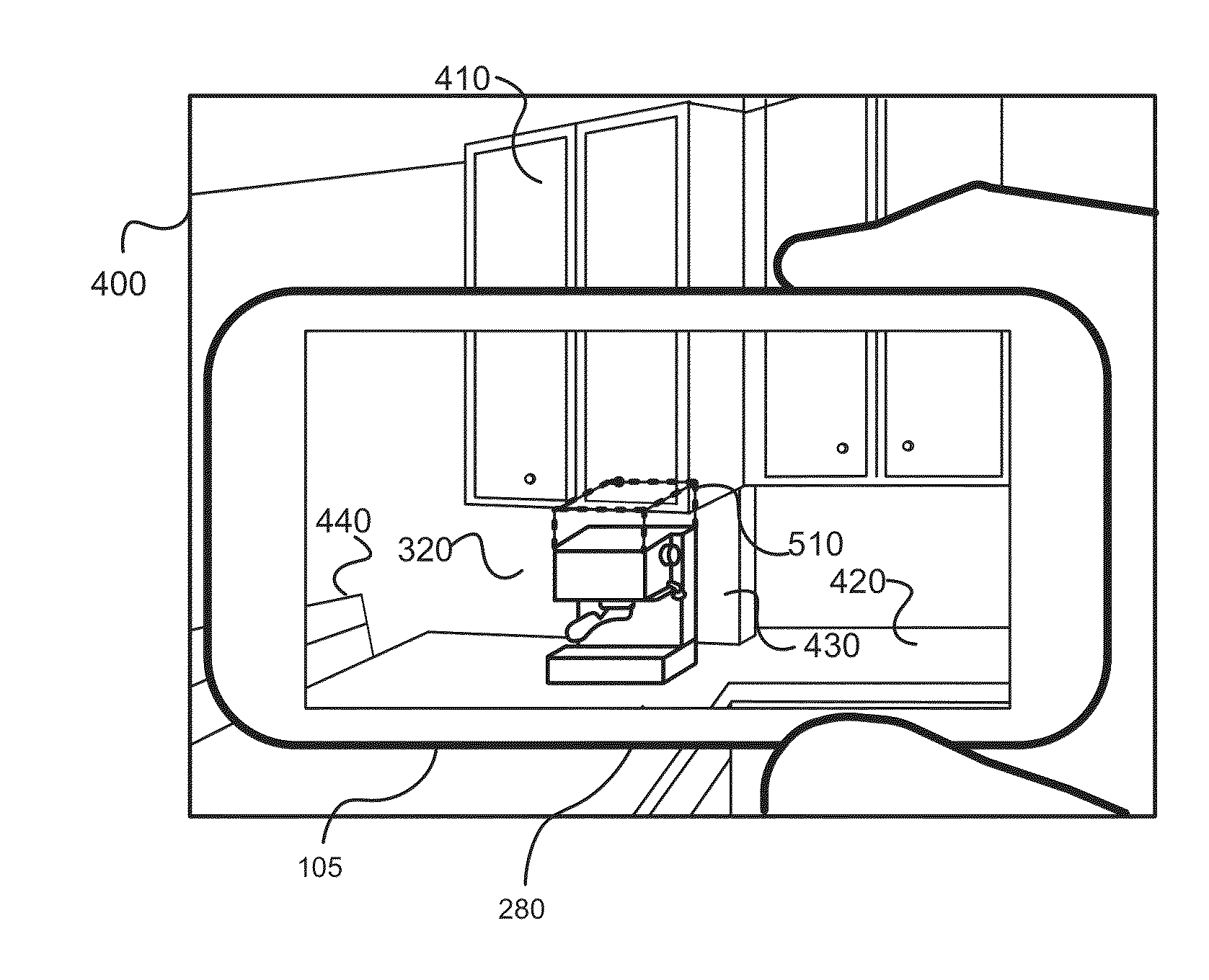

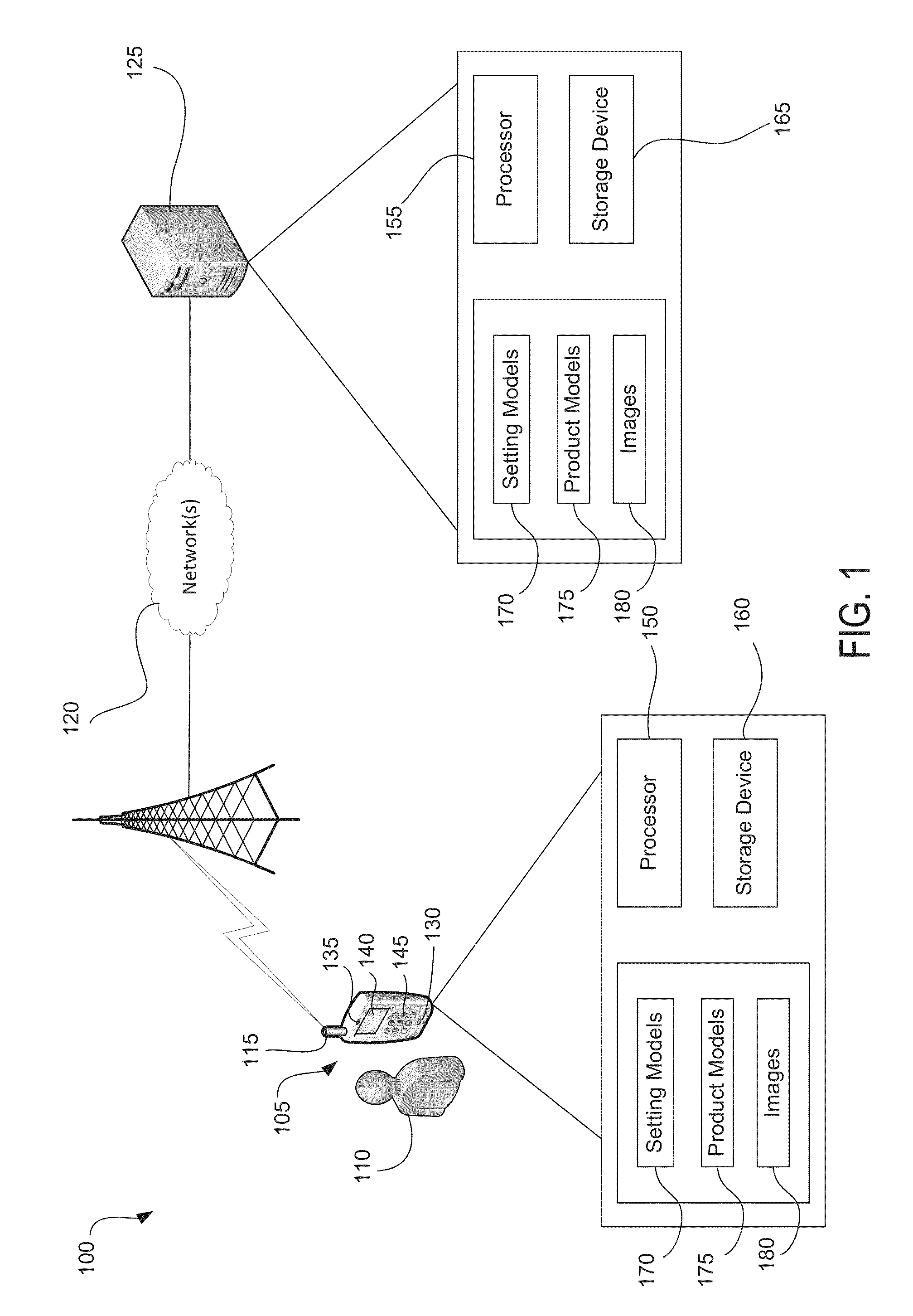

System and method for presenting true product dimensions within an augmented real-world setting

ActiveUS20140285522A1Cathode-ray tube indicatorsBuying/selling/leasing transactionsOperation modeHuman–computer interaction

Methods, systems, computer-readable media, and apparatuses for presenting a representation of an augmented real-world setting are presented. In some embodiments, a method includes presenting a representation of an augmented real-world setting. The method includes capturing a plurality of images of a real-world setting. The method also includes analyzing one or more real-world objects within the plurality of images of the real-world setting. The method further includes receiving information pertaining to a real-world product, wherein the information is indicative of first physical dimensions of the real-world product during a first mode of operation and second physical dimensions of the real-world product during a second mode of operation and overlaying an augmented reality object depicting the real-world product during the first mode of operation, and having the first physical dimensions, within at least one of the plurality of images of the real-world setting, based at least in part on the analyzing step.

Owner:QUALCOMM INC

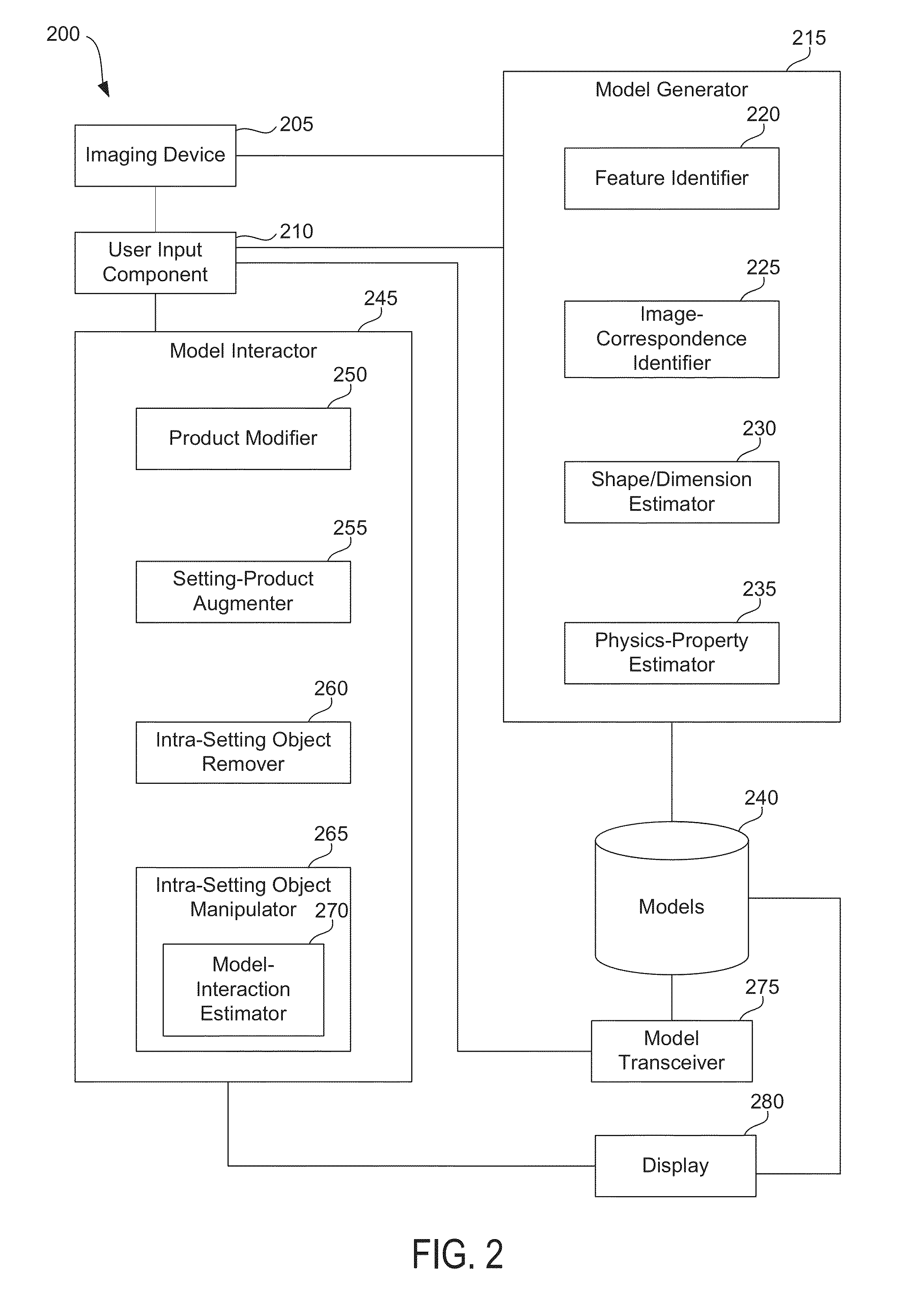

Merchandising tray for food products and the like

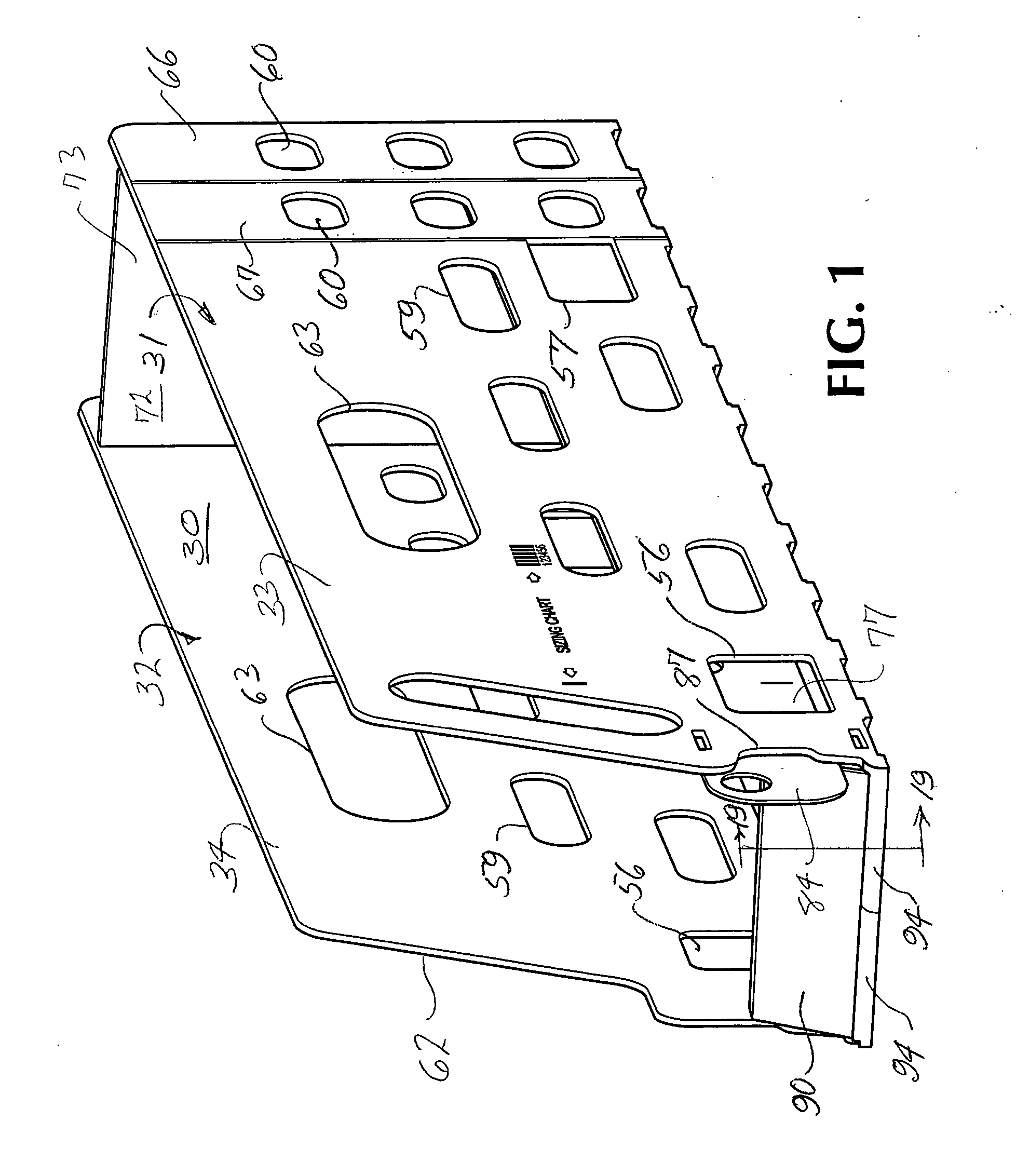

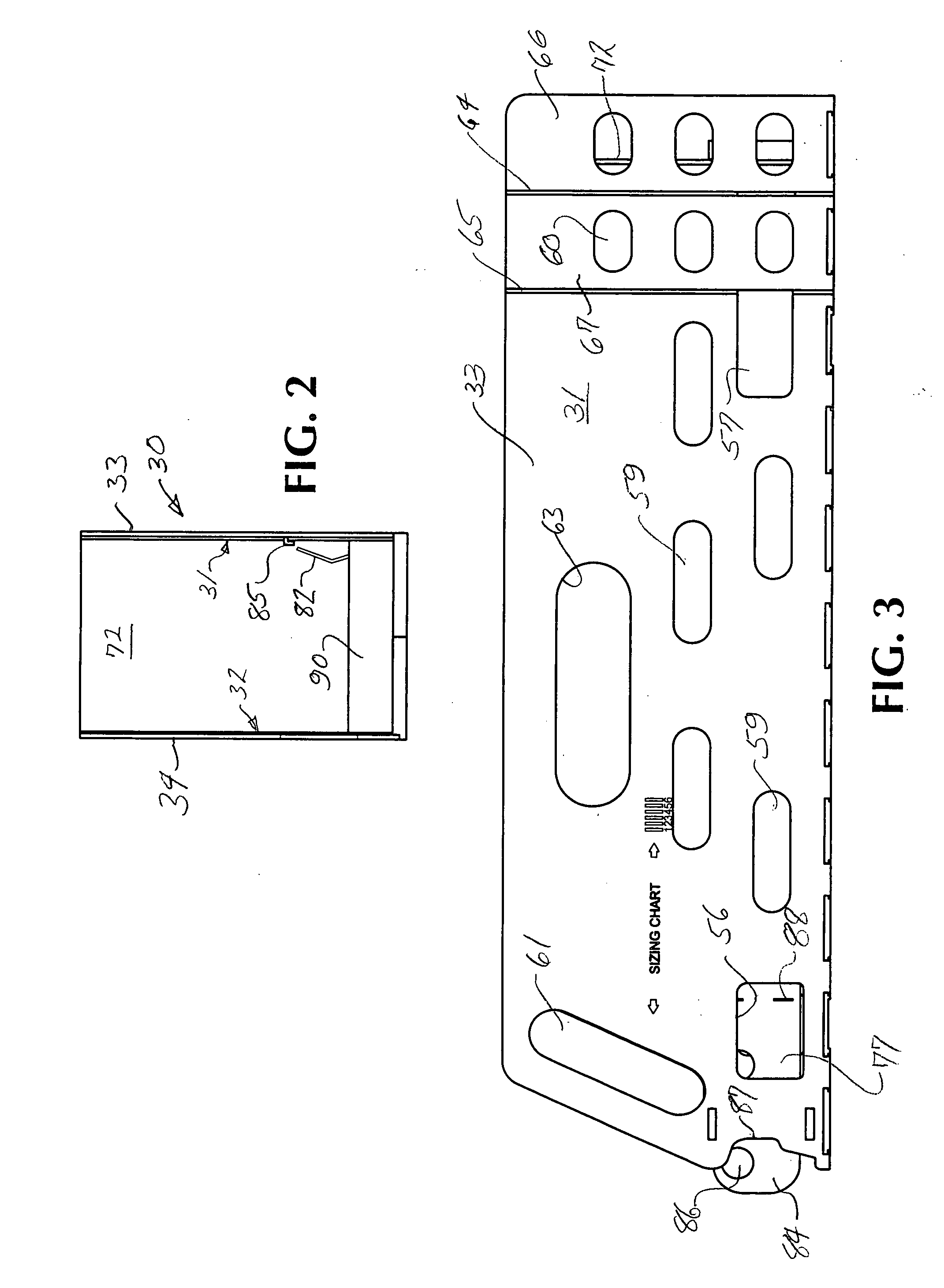

ActiveUS20070075028A1Easy to identifySpace maximizationShow cabinetsRacksPlastic materialsFood products

A two-piece, adjustable width merchandising tray for the organized display of multiple product containers. Two L-shaped tray sections, formed of plastic material. The bottom portions of the two L-shaped sections are provided with laterally extending, interengaging fingers that enable the width of the tray to be adjusted for different product sizes while maintaining substantial continuity to the surface of the bottom structure for containment of product leakage. An asymmetrical side wall arrangement with a forwardly projecting hand grip at the front of one of the side walls enables individual trays to be removed and replaced from a closely packed array of trays arranged in side-by-side fashion. The trays can be conveniently lifted and carried for product restocking, reorganizing, tray cleaning, etc. A simple pull strip and paddle arrangement enables product to be fronted at all times. Double stacking of product containers is also accommodated. Densely stacked, attractive, and efficiently serviced product displays are facilitated.

Owner:TRION IND

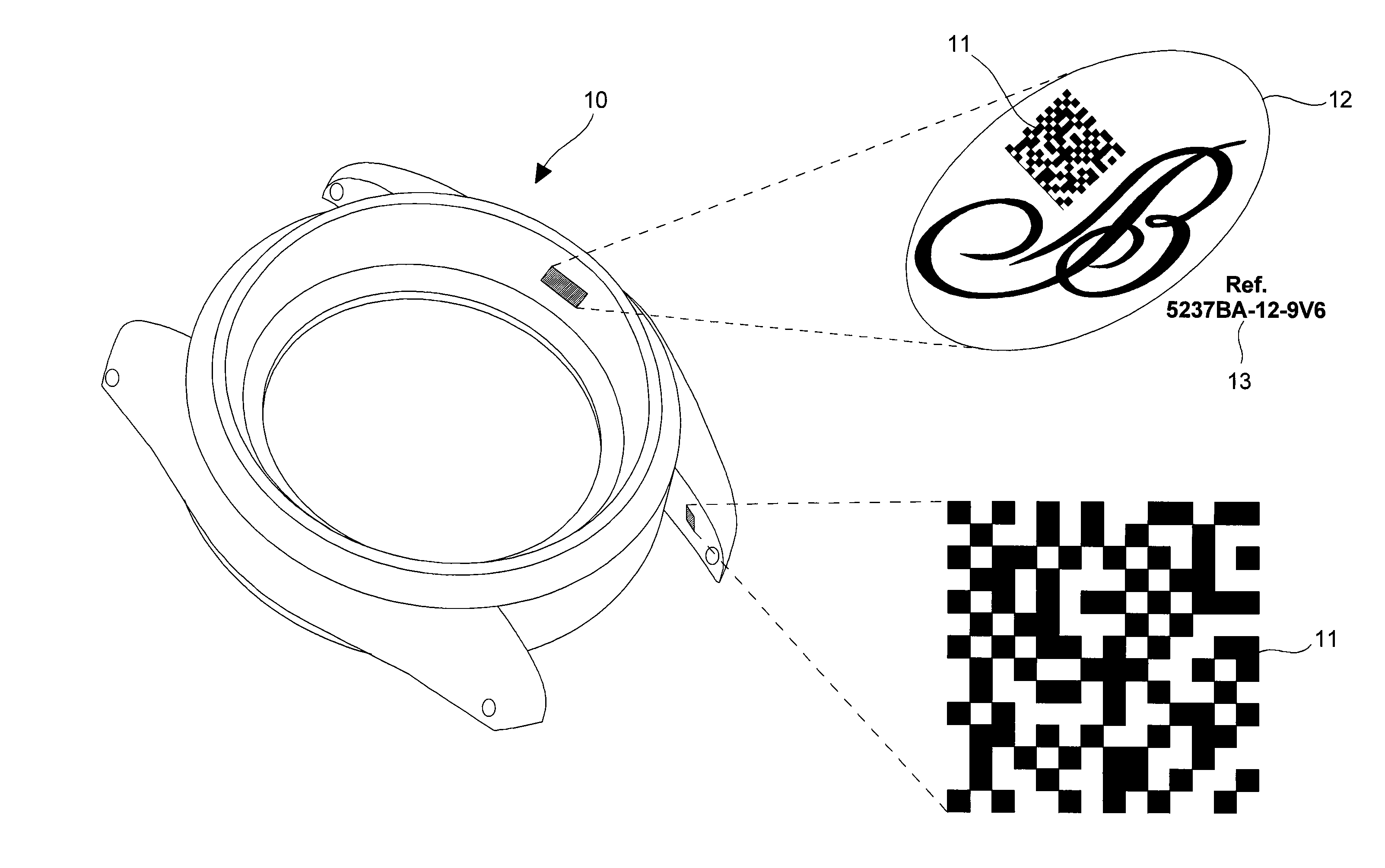

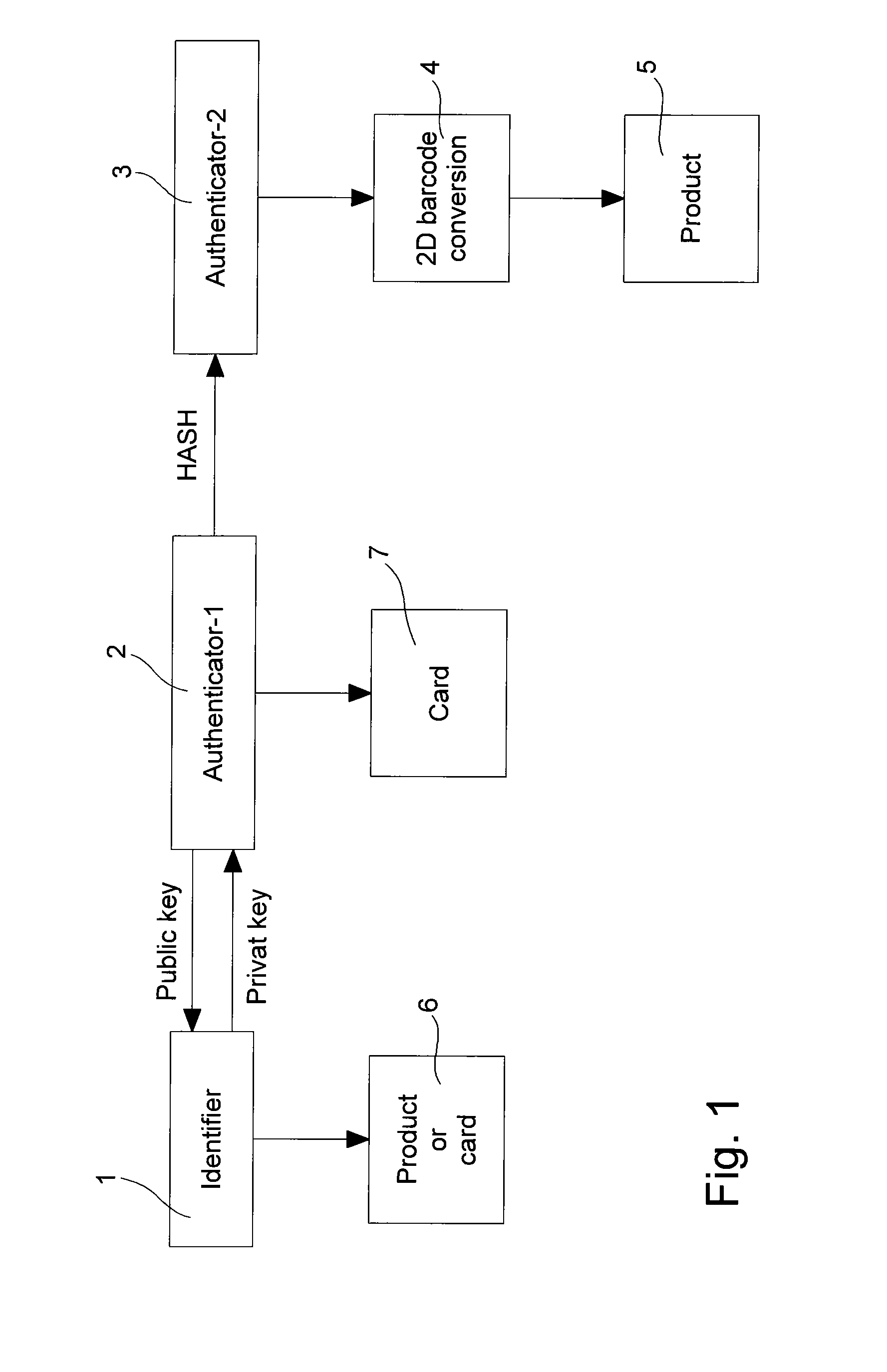

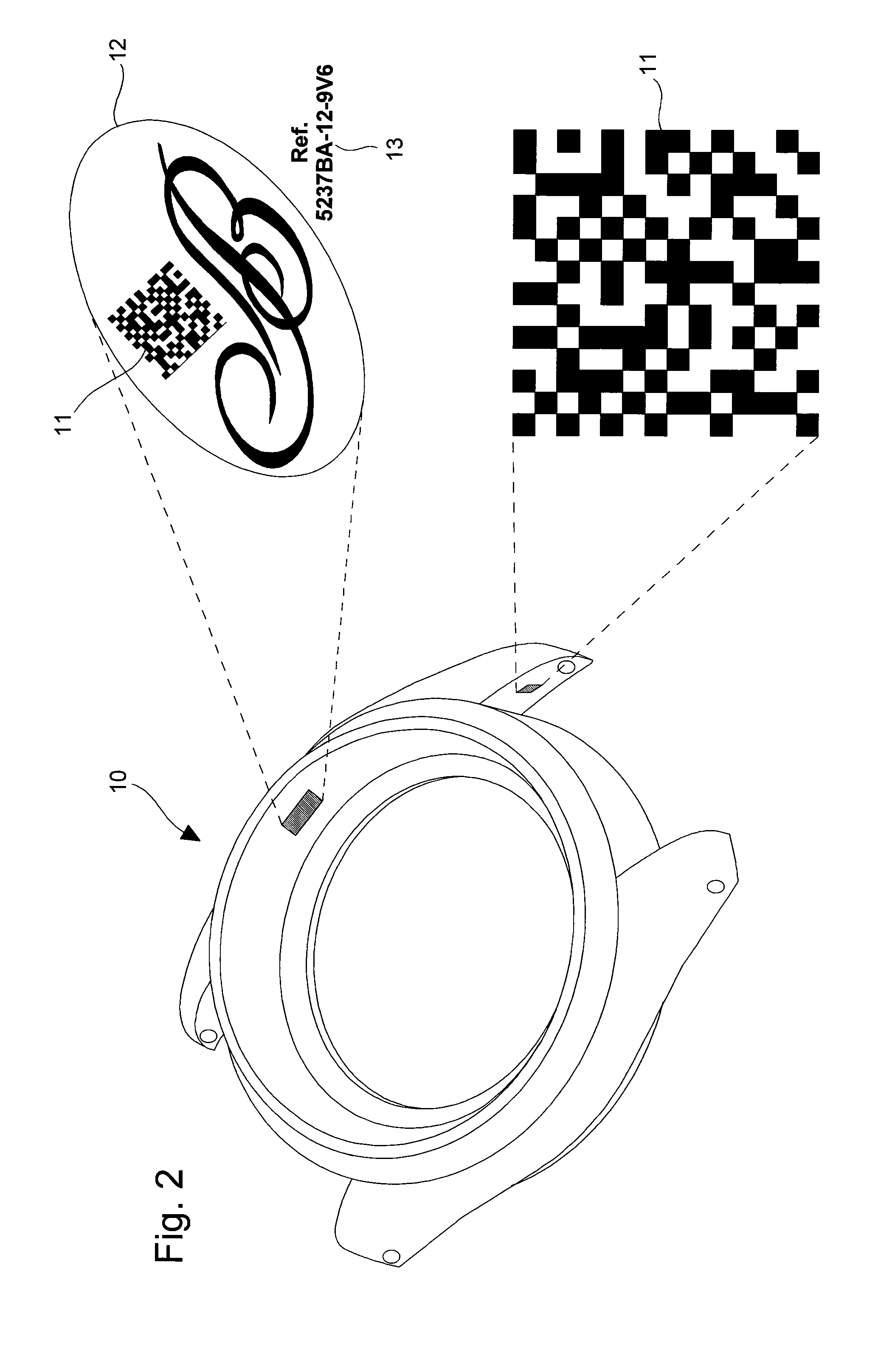

Method of coded marking of a product of small size, and marked product obtained according to said method

InactiveUS20090302123A1Small sizeImprove securityRecord carriers used with machinesBarcodeComputer science

The method is for coded marking of a product of small size, such as horological or jewelry product (10). The method consists in carrying out a first mathematical operation of encrypting an identifier (13), such as a serial number of the product to be marked using a specific security algorithm key to obtain a first authenticator. The first authenticator includes a first data length defined by a first large number of alphanumerical characters. This first authenticator is encrypted using a second mathematical operation using a Hash type function into a second authenticator. This second authenticator includes a second data length defined by a second reduced number of alphanumerical characters shorter than the first number of characters. The second authenticator is converted into a coded image, which is preferably a two dimensional barcode (11) so as to be placed on the product as the coded mark in order to allow said product to be authenticated.

Owner:MONTRES BREGUET

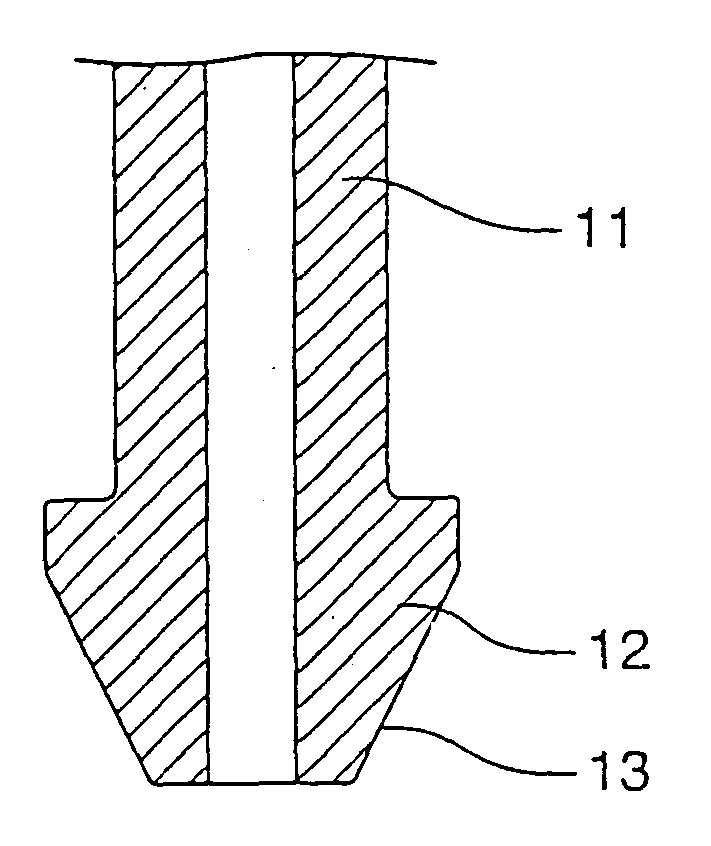

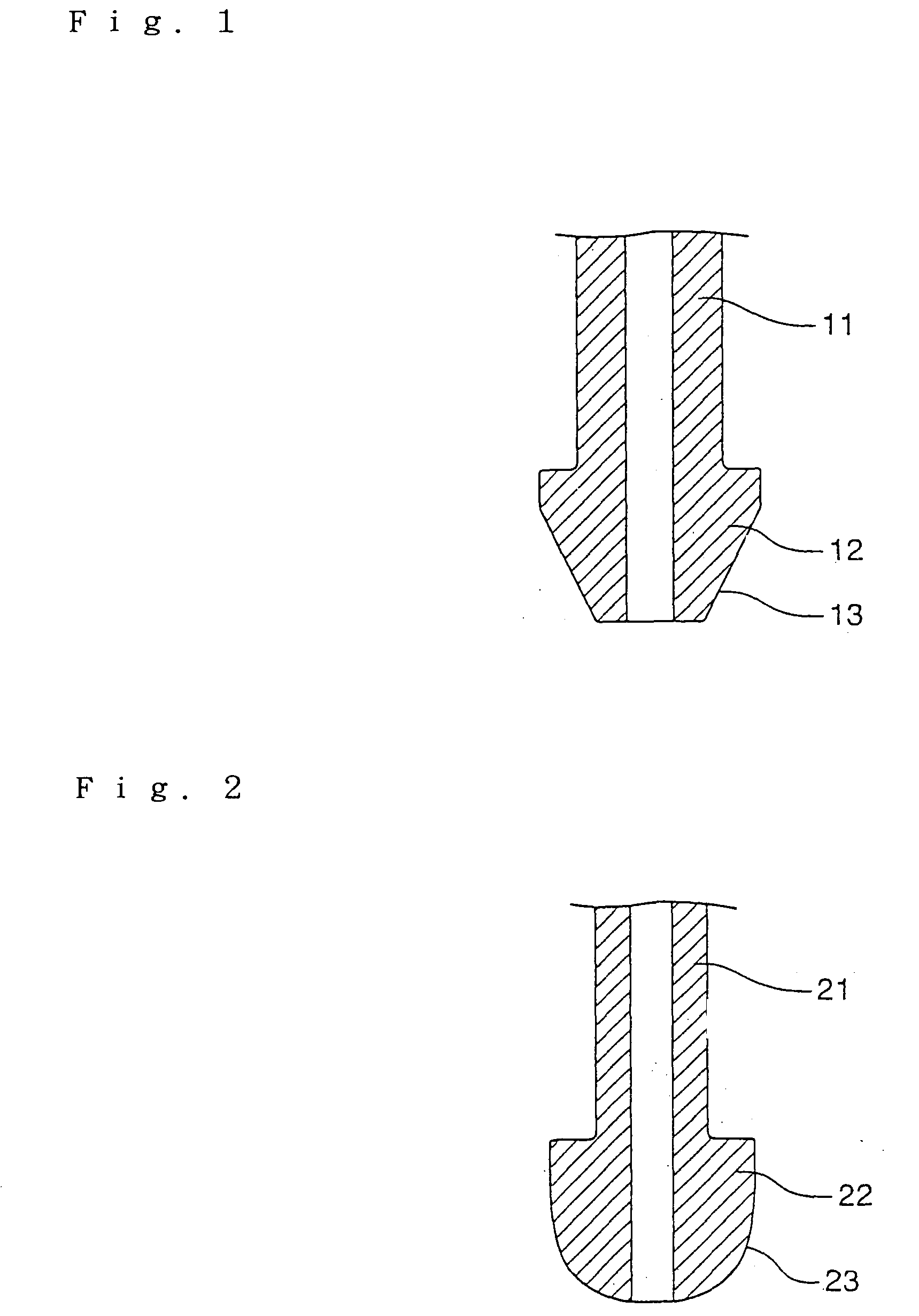

High-pressure fuel injection pipe

InactiveUS20050005913A1Improve fatigue strengthIncrease internal pressureMachines/enginesSpecial fuel injection apparatusInternal pressureCavitation

A high pressure fuel injection pipe is provided for a diesel engine and has excellent internal pressure fatigue resisting characteristics, vibrational fatigue resisting characteristics and cavitation resisting property and sheet face flawing resisting property, and can be made thin and light in weight. In the high pressure fuel injection pipe, pipe extension and heat treatment are repeated by using a header manufactured by transformation induced plastic type strength steel, and processing for depositing residual austenite is then performed and final pipe extension processing is performed, and a joint portion is molded and bending processing is performed without performing perfect annealing at the size of a product.

Owner:USUI KOKUSAI SANGYO KAISHA LTD

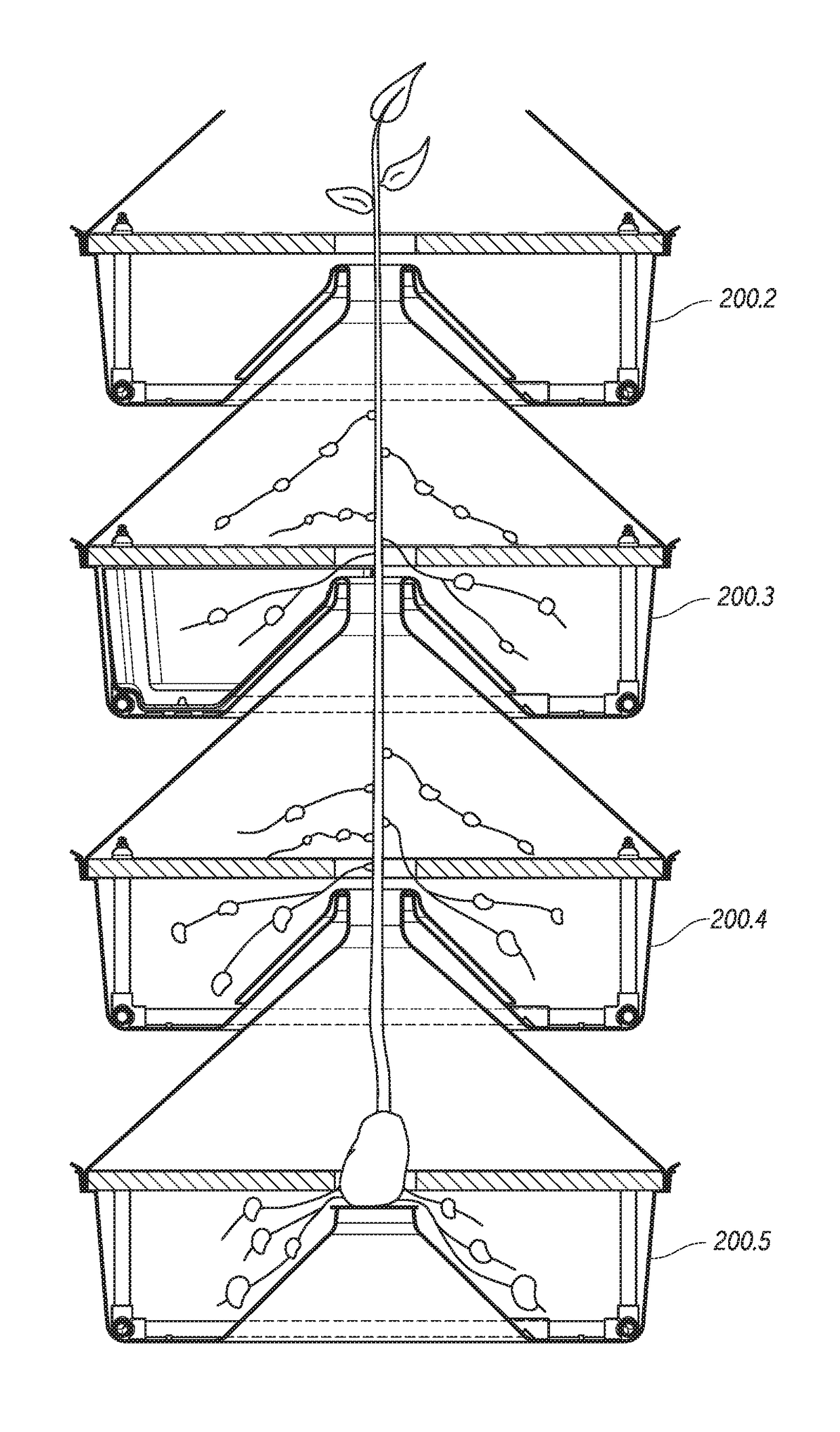

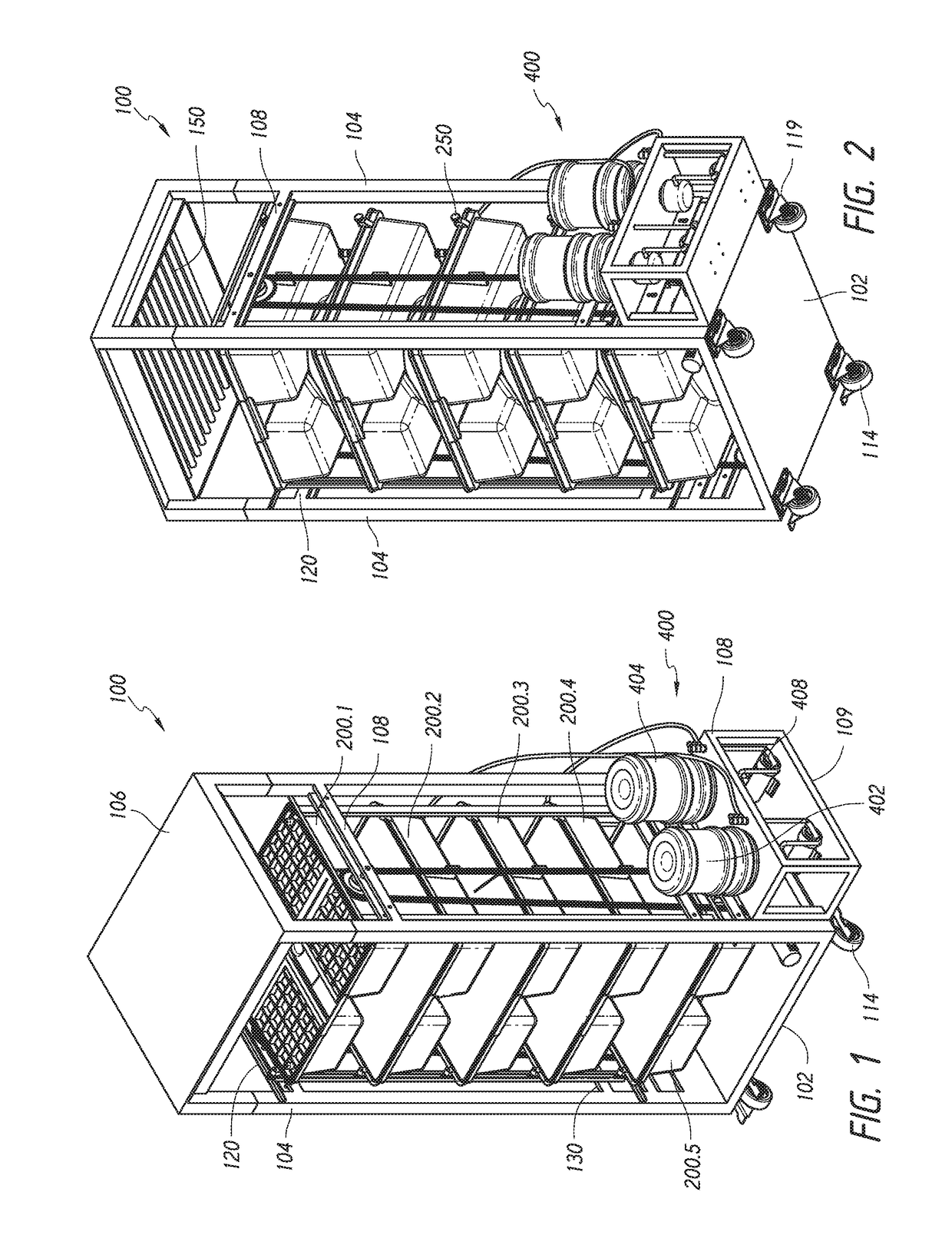

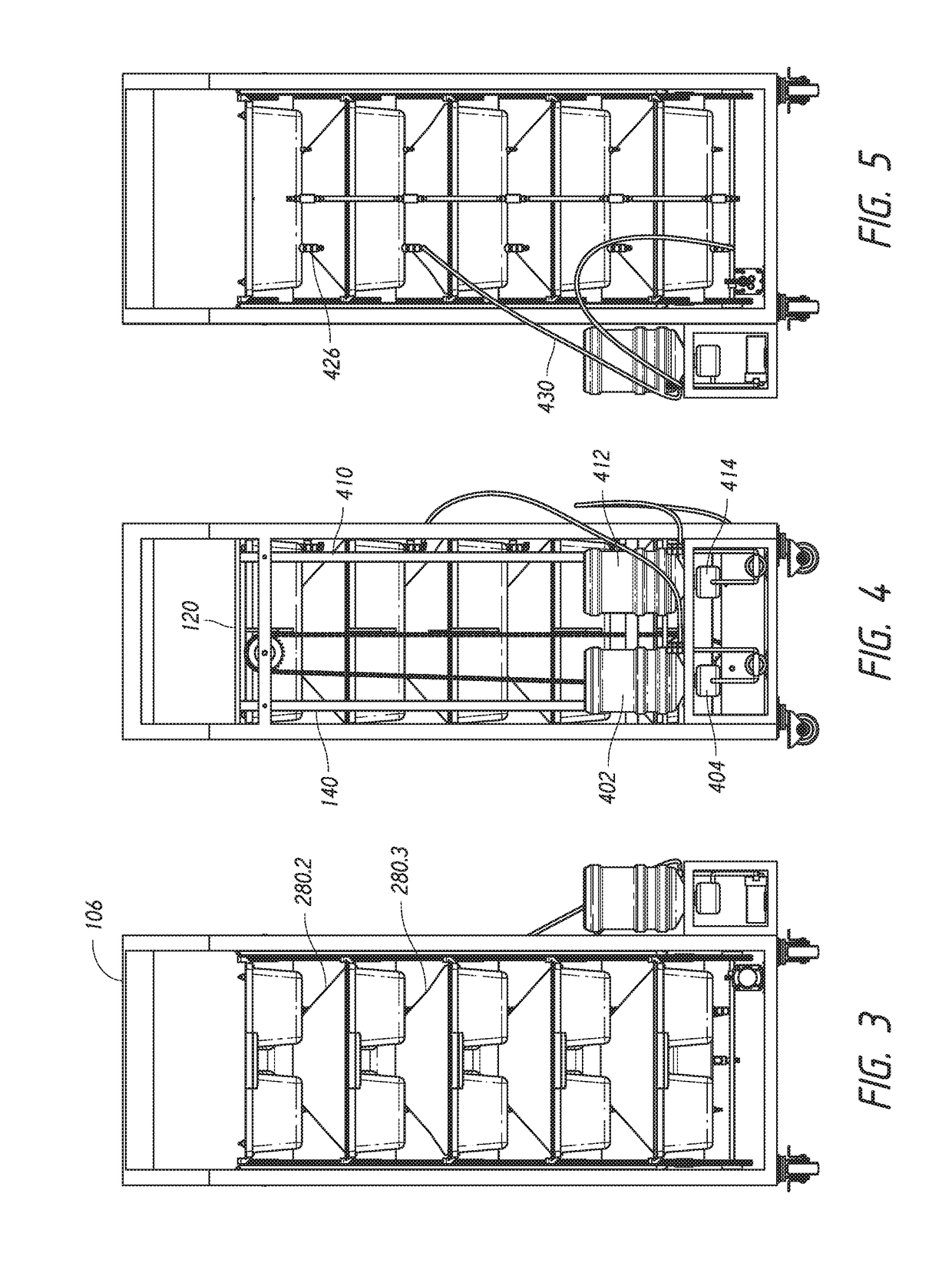

Growing systems and methods

Growing systems may include a number of modular growing chambers adapted to be configured in a stacked arrangement with each growing chamber surrounding a corresponding portion of the plant. The grow chambers may be selectively added or removed during plant growth, such that different sections of the growing plant may be influenced differently using aeroponic, hydroponic or other growing techniques. The grow chamber stack may be portable and provided with integrated or independent lifting devices to assist an operator in adding or removing chambers from the stack. Three growing processes may be facilitated using such systems. These include a process for producing assorted product from a single plant for simultaneous harvest, a process for producing an extended harvest of a desired size product from a single plant, and a process for extending the productive life of a plant and provide for multiple, continued, and perpetual harvest.

Owner:MASSIVIA GROW HLDG LLC

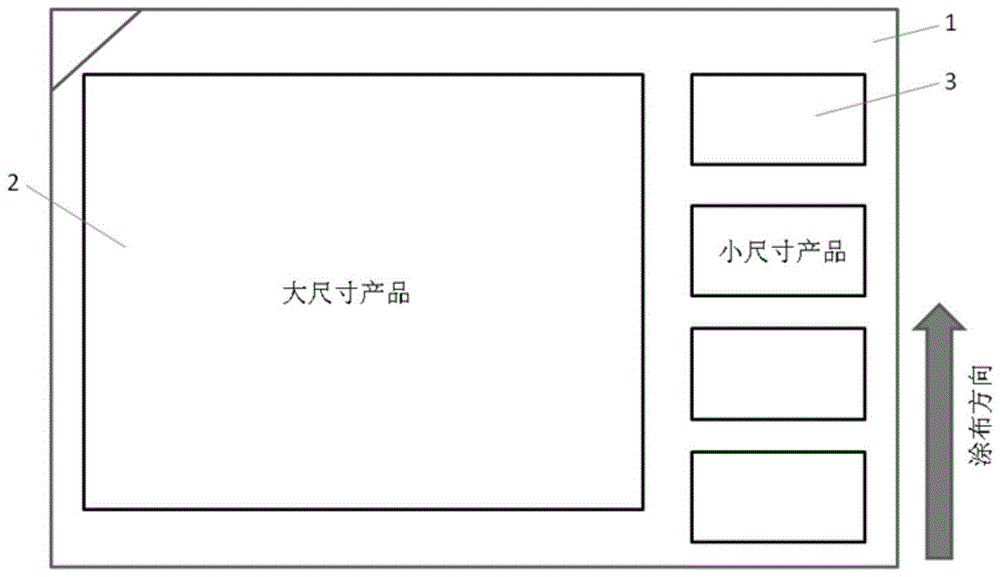

Combined nesting die-cutting process

The invention relates to a combined nesting die-cutting process for nesting and combining products with different sizes with one another and processing a plurality of types of products in turn. The combined nesting die-cutting process overcomes the defect that layout die cutting is performed on each product singly and a large number of raw materials are wasted in the prior art. The combined nesting die-cutting process comprises the following steps of: 1, selecting a product combination capable of being nested for die cutting; 2, designing a nested combination arrangement; 3, customizing a cutting die; and 4, performing machine die cutting according to the arrangement combination design of the step 2 and the cutting die customized by the step 3. The combined nesting die-cutting process enlarges the existing method which uses a single product as a visual field to take a layout design into account in to a mode which uses all products with the same or partially same materials ad structures as the visual field to take the layout design into account; besides, the combined nesting die-cutting process ensues that discharged wastes of a hollow part of a big product can be used as a raw material of a small product so as to improve the utilization ratio of the raw materials and save the cost by nesting, combining and arranging a plurality of products with different sizes and non-overlapping edges together and then performing the die cutting in an order from inside to outside or from outside to inside.

Owner:沈振华

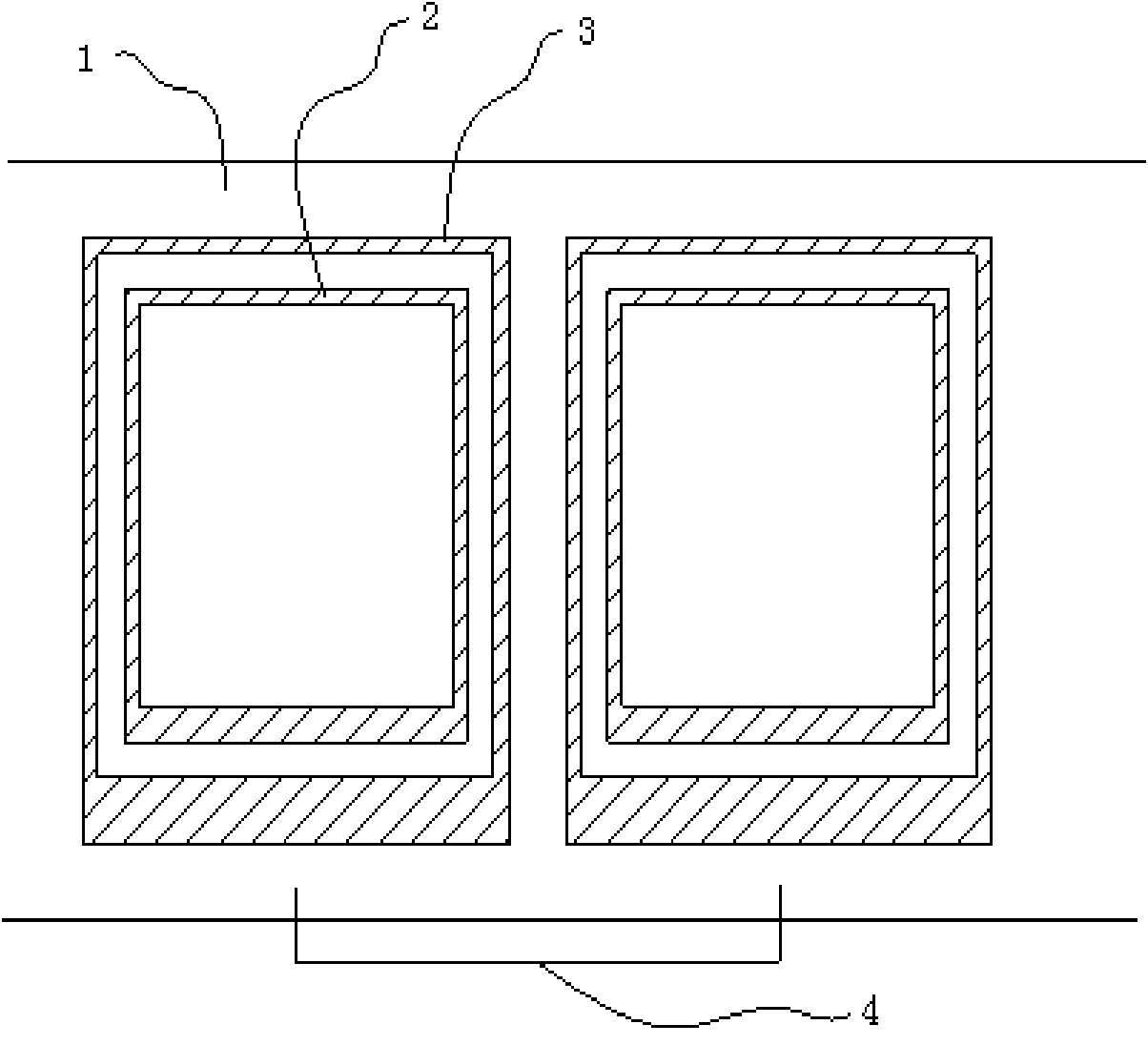

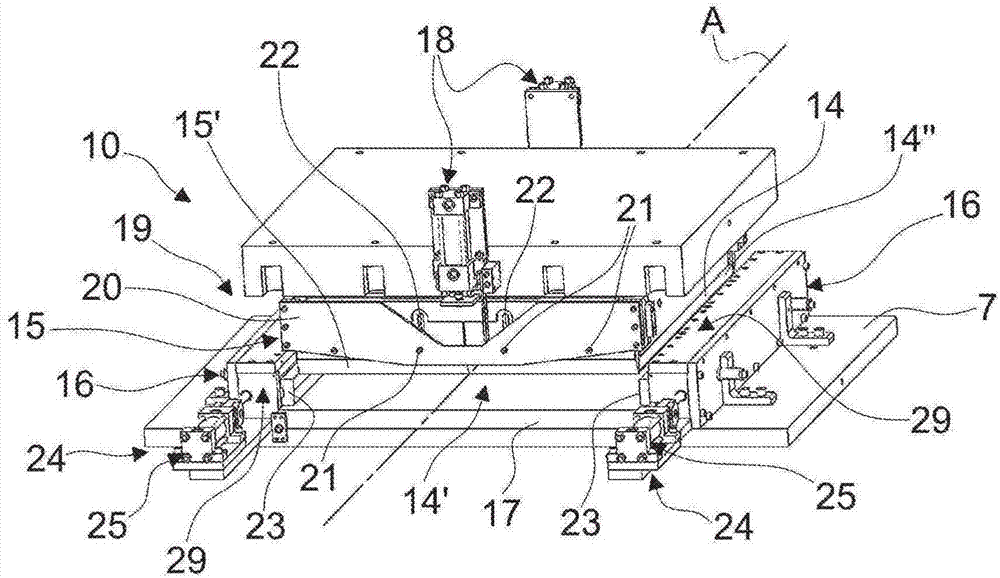

Backlight module material reliability test fixture

ActiveCN103676248AQuick testEfficient testingOptical apparatus testingNon-linear opticsEngineeringTest fixture

The invention relates to a backlight module in the field of display, in particular to a backlight module material reliability test fixture. The test fixture comprises a fixture base and four fixture side frames, and the four fixture side frames are arranged on the top surface of the fixture base and sequentially perpendicularly connected with one another, so that a cavity structure is formed. The test fixture can more quickly and more efficiently test the reliability of optical materials, greatly shorten the development cycle and decrease the risk of development; because the structure design of the adjusting side frames is adopted, the applicable testable size range is wide, the test fixture can be freely adjusted according to design sizes, so that the test fixture can be applied to test a number of products with different sizes, and thereby the cost is greatly reduced.

Owner:BOE TECH GRP CO LTD +1

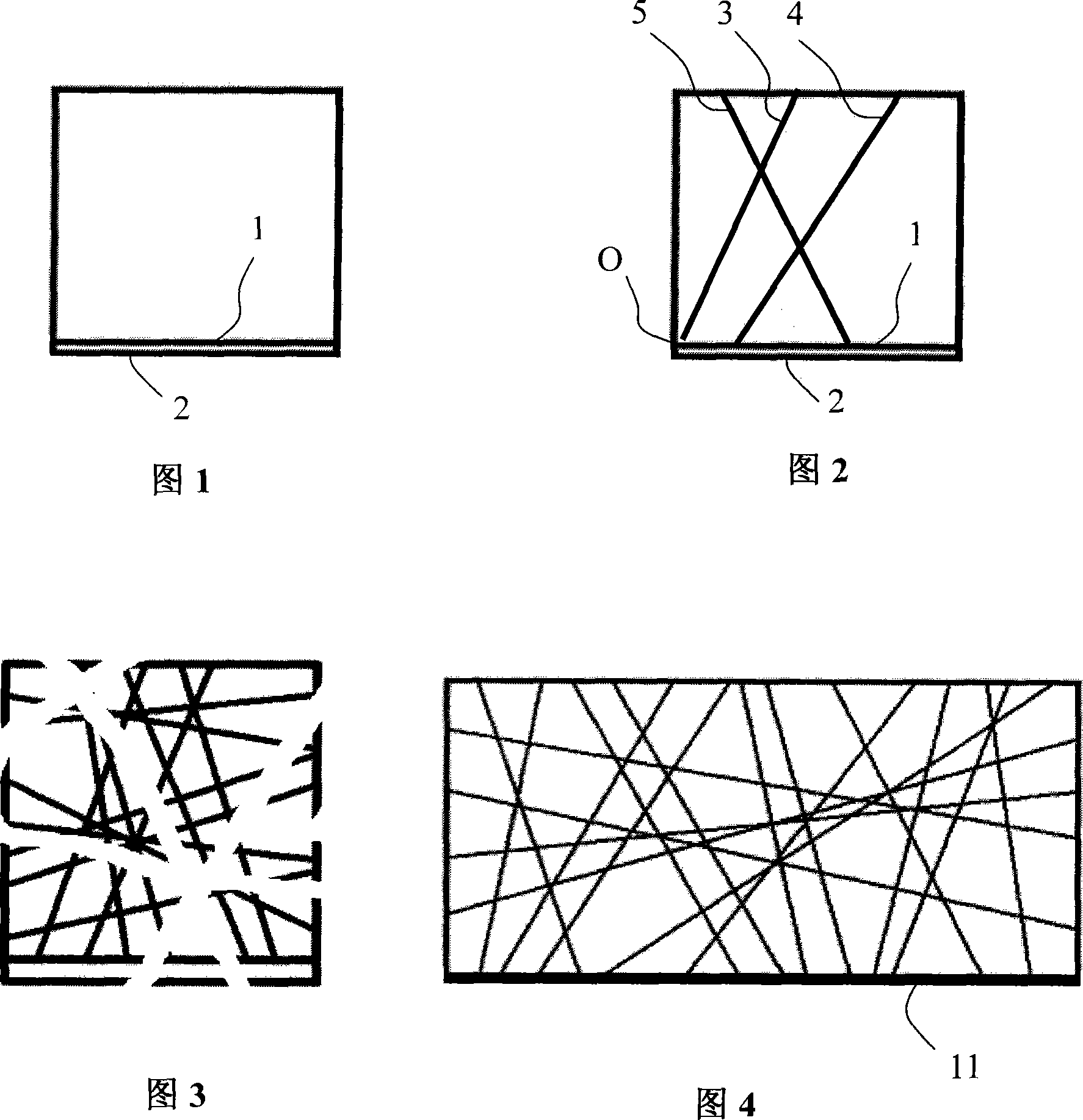

2D linear graphics coding anti-fake method

ActiveCN101105833AAvoid crackingDifficult to imitateDigitally marking record carriersCharacter and pattern recognitionGraphicsAlgorithm

The invention discloses a two-dimensional linear graphic coding counter-forgery method that can be printed on the surface of products directly. The method has the advantages of strong randomness, being difficult to be decoded, and suitability for small-sized products. The method includes generation, printing, and validation of linear graphs. As for the generation of linear graphs, a computer generates a code at least including linear angle information, and draws the linear corresponding with each code in the rectangle base frame; as for the identification of linear graphs, a picture collection device obtains the pictures of linear graphs, and obtains their black-and-white edge pictures after the pre-treatment, and then obtains each straight line's slope and interception information according to black-and-white edge pictures, and eventually calculates the corresponding code. The code is generated by the computer. At last, product information is validated through the code database of the validation system.

Owner:李曙光 +1

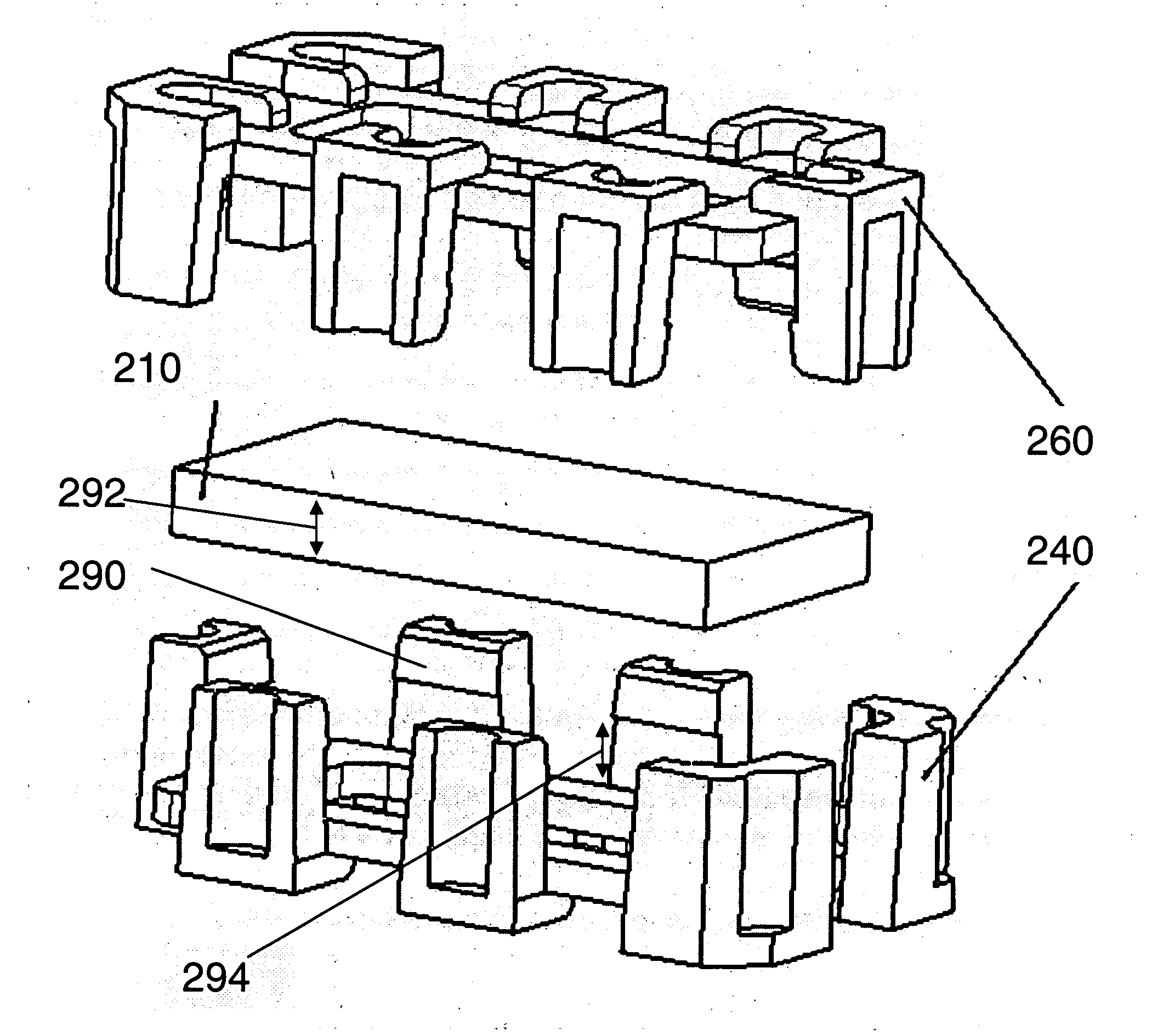

Flexible interlocking-column packaging assembly

A packaging assembly comprising a standard molded cushion solution that can accommodate variations in dimensions of predetermined products, including weight, while providing protection to an equipment component (or other fragile or breakable item) enclosed therein, ease in use during pre-packing and packing of an equipment component for transport, shock protection during transport, and is economically suited for its end use, is provided for. The present invention is a molded, cushion having interlocking columns which adjust the contacting areas of the cushion in relation to the product height and / or weight differences. The present invention is advantageously designed using specific geometries and interlocking columns which, contrary to traditional designs, benefit from the stressing and flexing characteristics of paper fiber.

Owner:LENOVO PC INT

Elastic reusable wrapping product and system

InactiveUS20070056870A1Easy to insertEasy to acceptPackage recyclingOther accessoriesEngineeringStandard product

Owner:ALPS ELECTRIC LDT

Manufacturing method for large-dimension high-precision samarium-cobalt magnet

ActiveCN106158200AOvercome the problem of difficult processingInductances/transformers/magnets manufactureMagnetic materialsSamarium–cobalt magnetMagnetic poles

The invention relates to a manufacturing method for a large-dimension high-precision samarium-cobalt magnet. The manufacturing method comprises the steps of trimming, roughly grinding, vertically grinding, scribing lines, horizontally grinding, assembling and excircle grinding. According to the manufacturing method, assembling and gluing steps are performed; small-dimension products are manufactured firstly; then the small-dimension products are glued into large-dimension products; the problem of difficulty in manufacturing the large-dimension magnet is solved; geometrical tolerance of perpendicularity, depth of parallelism and cylindricity and the like is ensured through the processes of excircle grinding, horizontally grinding and the like; meanwhile, a technological method for marking magnetic pole boundary under a non-magnetic state is provided; and therefore, a feasible manufacturing scheme is provided for products with relatively large dimensions and relatively high requirement on tolerance.

Owner:杭州科德磁业有限公司

Support for utensils and napkin holder

A support for utensils and napkins. This support has three sections with each able to hold at least one utensil without touching the eating surface. The individual sections are connected to each other along the long sides. There are two support walls attached at the outer ends. All three sections are raised from the surface resulting in no contact with dirty or wet surfaces. The side walls are angled slightly outward for easy gripping and to better support the stacking of devices. The napkin section is below the utensil sections. The device will have two basic product sizes, one for an individual user with single sized utensil holder and one to hold utensils for many people. The device can be made of paper, cardboard, plastic, glass, or Styrofoam. When the device is made from glass or plastic, it can be made re-usable and dishwasher safe.

Owner:STECKER ABRAHAM HARRY

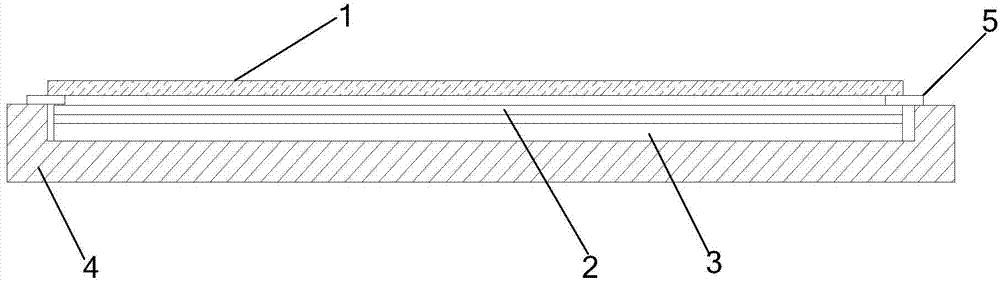

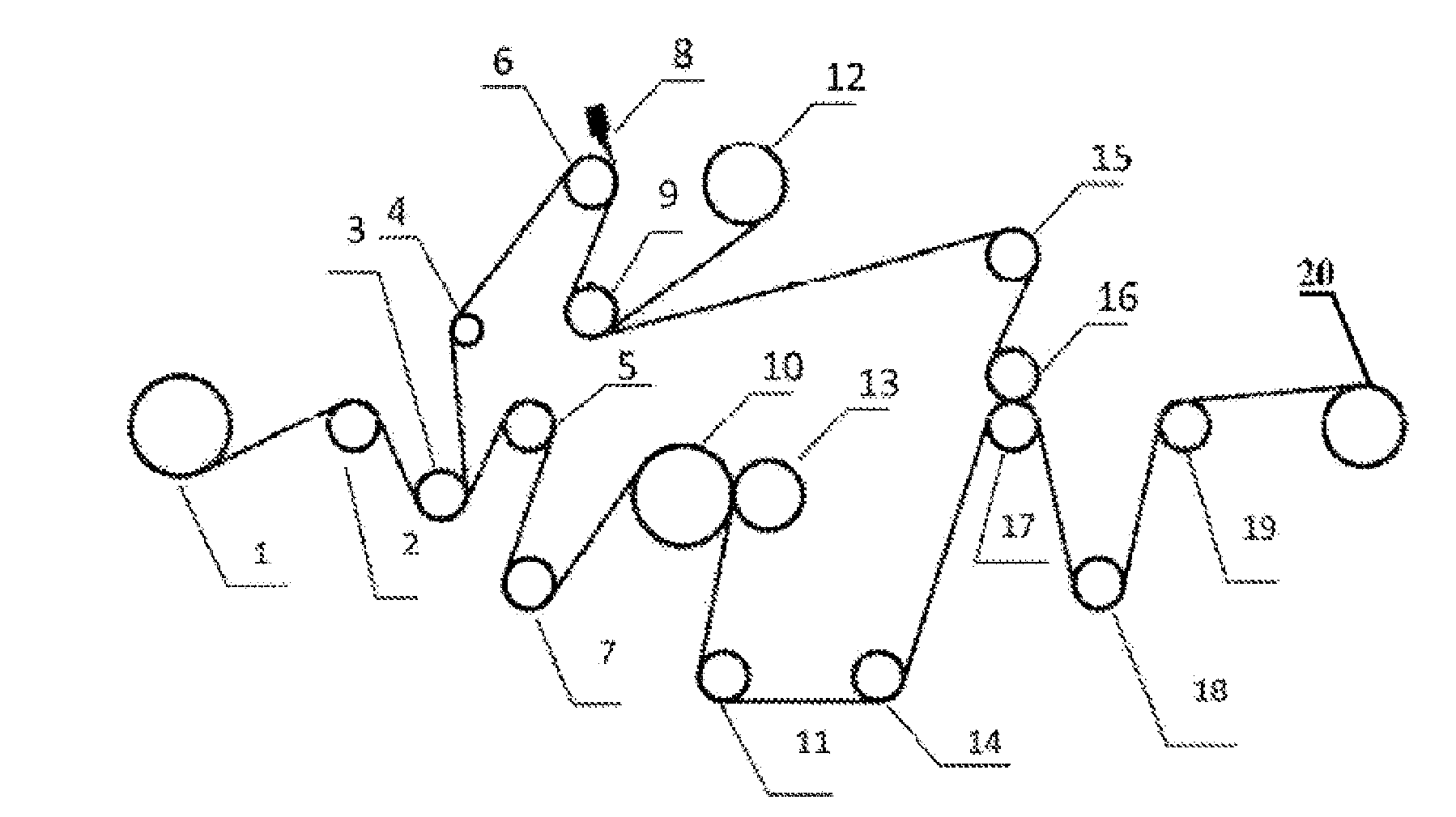

Apparatus for manufacturing light guide film

An apparatus for manufacturing a light guide film may comprise a feed roller, a receiving roller, a separating device, a hot press printing device and a recombining device. Firstly, the separating device may separate a protective layer from a substrate layer of the light guide film. Secondly, a surface of the substrate layer to be manufactured may be impressed with light guide dots by the hot press printing device, and the recombining device recombine the peeled protective layer to the substrate layer. And lastly, the finished light guide film is recycled by the receiving roller. The apparatus may have advantages such as high output and low cost, and it may manufacture a large dimensioned product.

Owner:SVG TECH GRP CO LTD +1

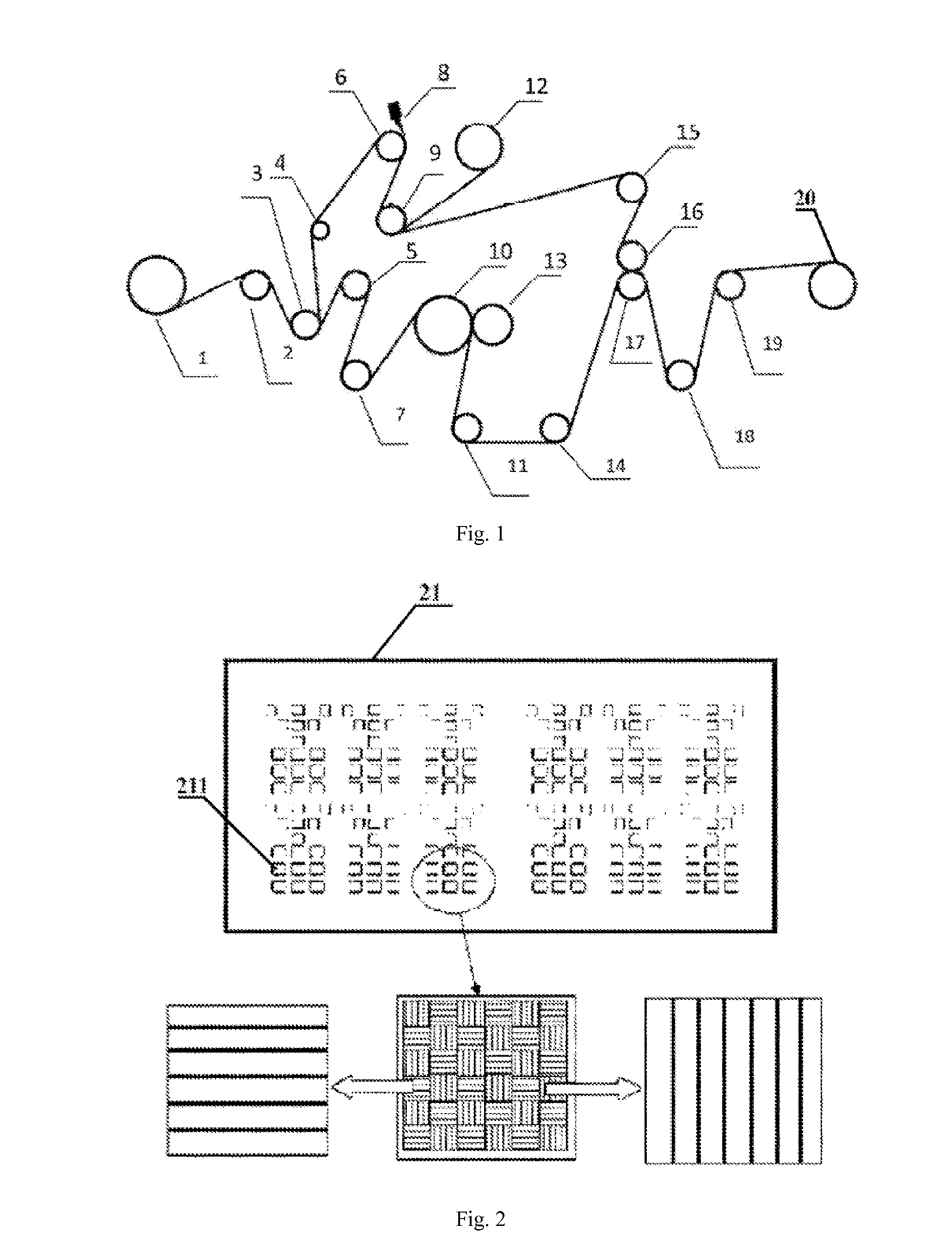

PIN needle position degree detection method for large-size product with sub-pixel precision

The invention provides a PIN needle position degree detection method for a large-size product with sub-pixel precision. By fixing positions of a camera and a light source and using a servo system to drive the product to move, the product is divided into a plurality of subsections used to respectively acquire images of each subsection. The common pixel points in each image are used to unify the image coordinate system of each subsection image. At the same time, a new reference coordinate system is established, and finally, the calculated distance between the needle point of the PIN needle and the new reference is compared with a set tolerance value, and therefore qualified products and non-qualified products are distinguished. According to the invention, the method of obtaining a size of alarge-size product by adopting an image stitching method is abandoned, and therefore errors caused by splicing can be greatly reduced, and the processing pixel has a sub-pixel function. In addition, the detection method is suitable for cameras of different brands, can be applied to detection of different products, and is high in universality and compatibility.

Owner:怡得乐电子(杭州)有限公司

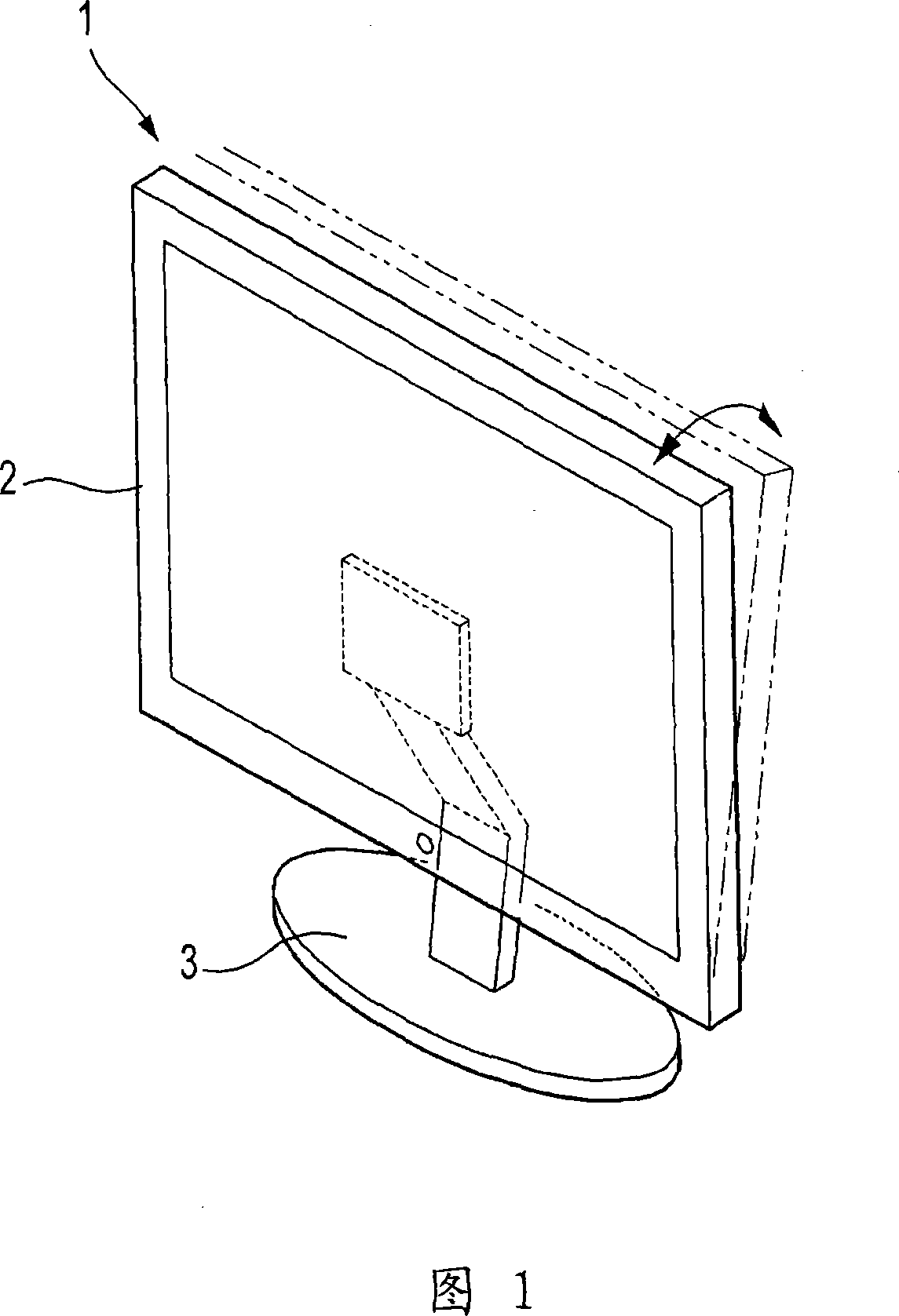

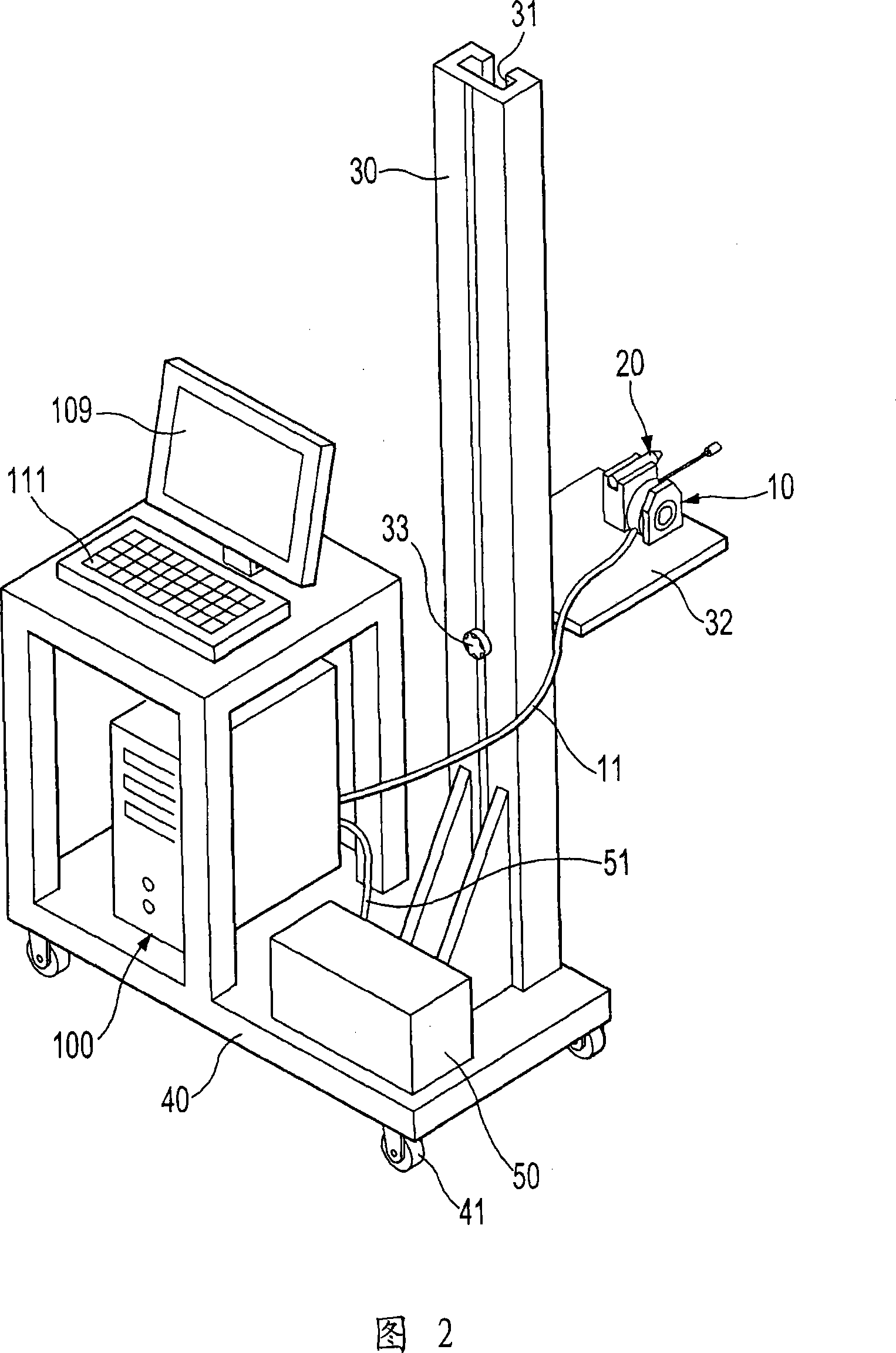

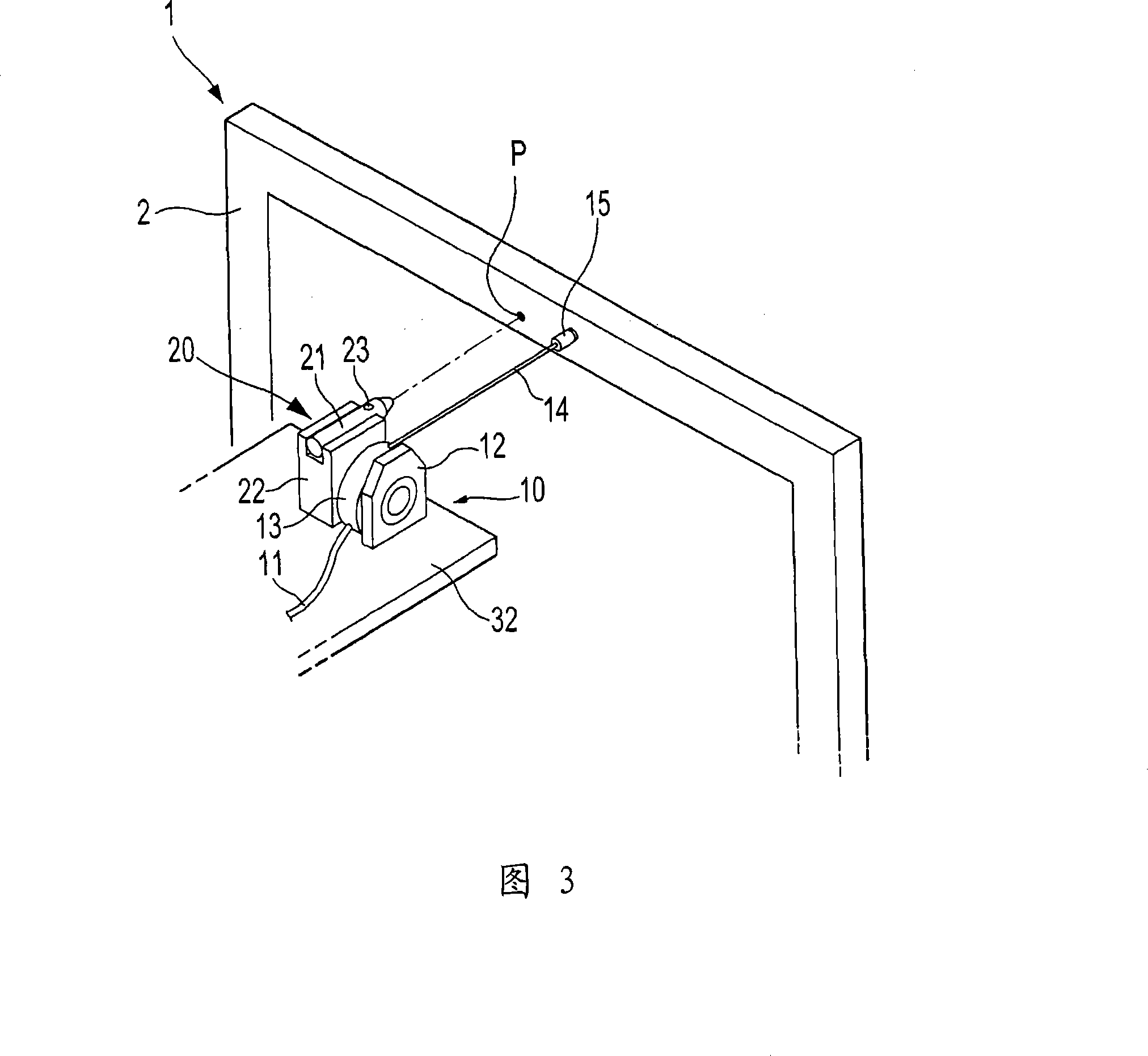

System and method for measuring the degree of wobble of image display device

InactiveCN101187571ASubsonic/sonic/ultrasonic wave measurementStatic indicating devicesDisplay deviceComputer science

A system and method for measuring the degree of a wobble of an image display device are disclosed. The system can quantitatively measure the degree of a wobble of a screen module of an image display device, resulting in the implementation of increased reliability of measured wobble data. The system can adjust the height of the image display device irrespective of the appearance of the product model, such that it can be widely applied to a variety of product models. The system is loaded on the support, and moves to another location, such that it can be easily adapted to measure the wobble of a large-sized product having difficulty in motion, resulting in greater convenience of use.

Owner:SAMSUNG ELECTRONICS CO LTD

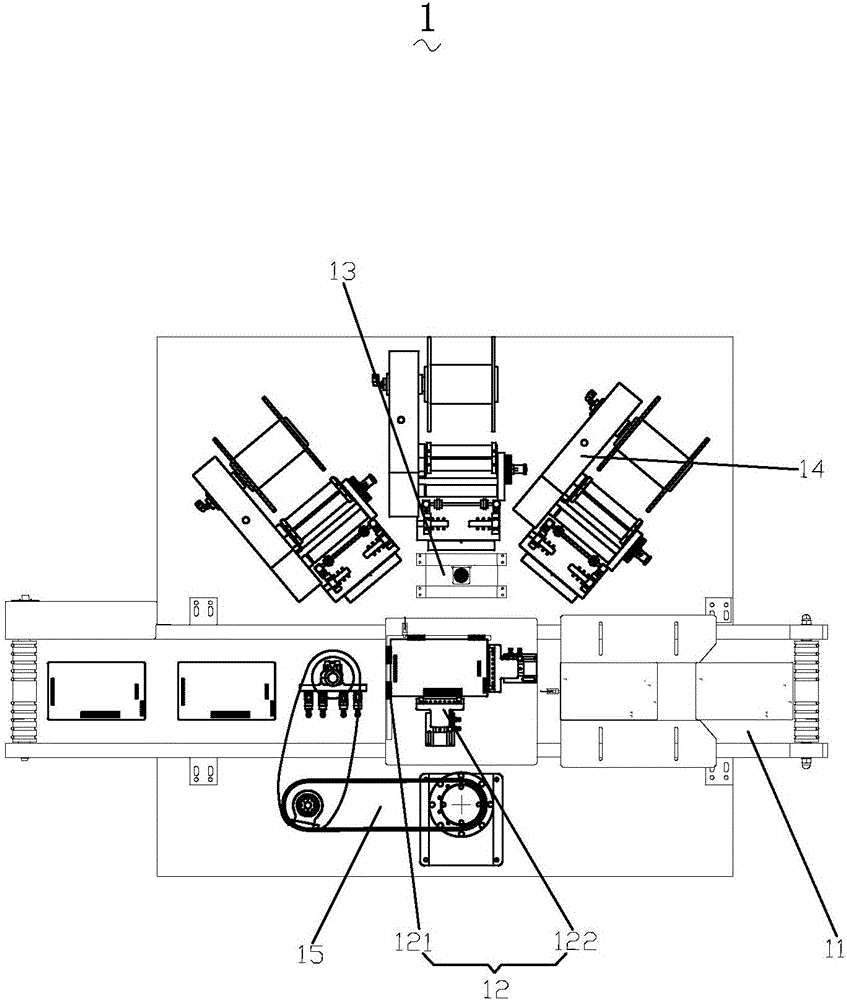

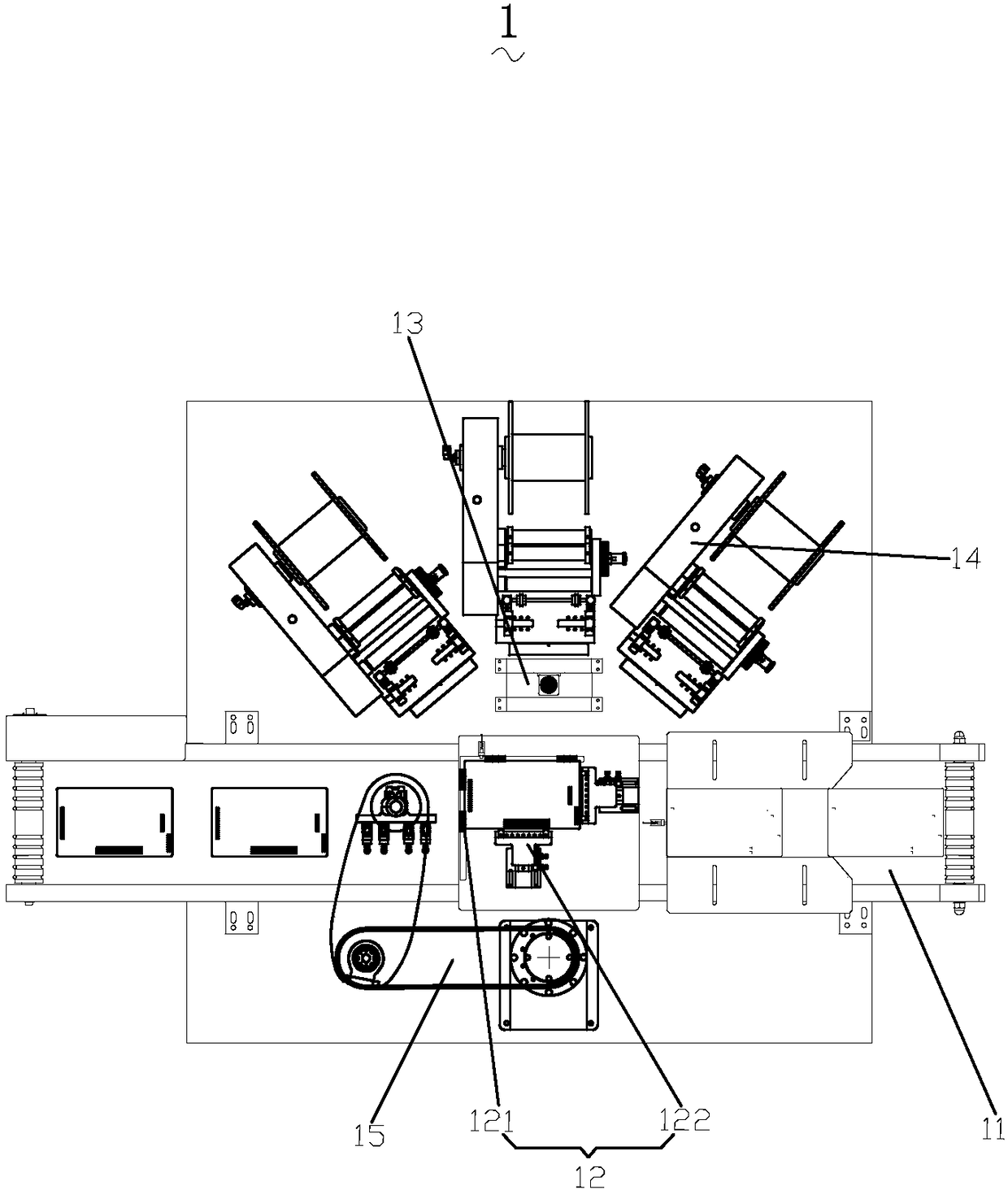

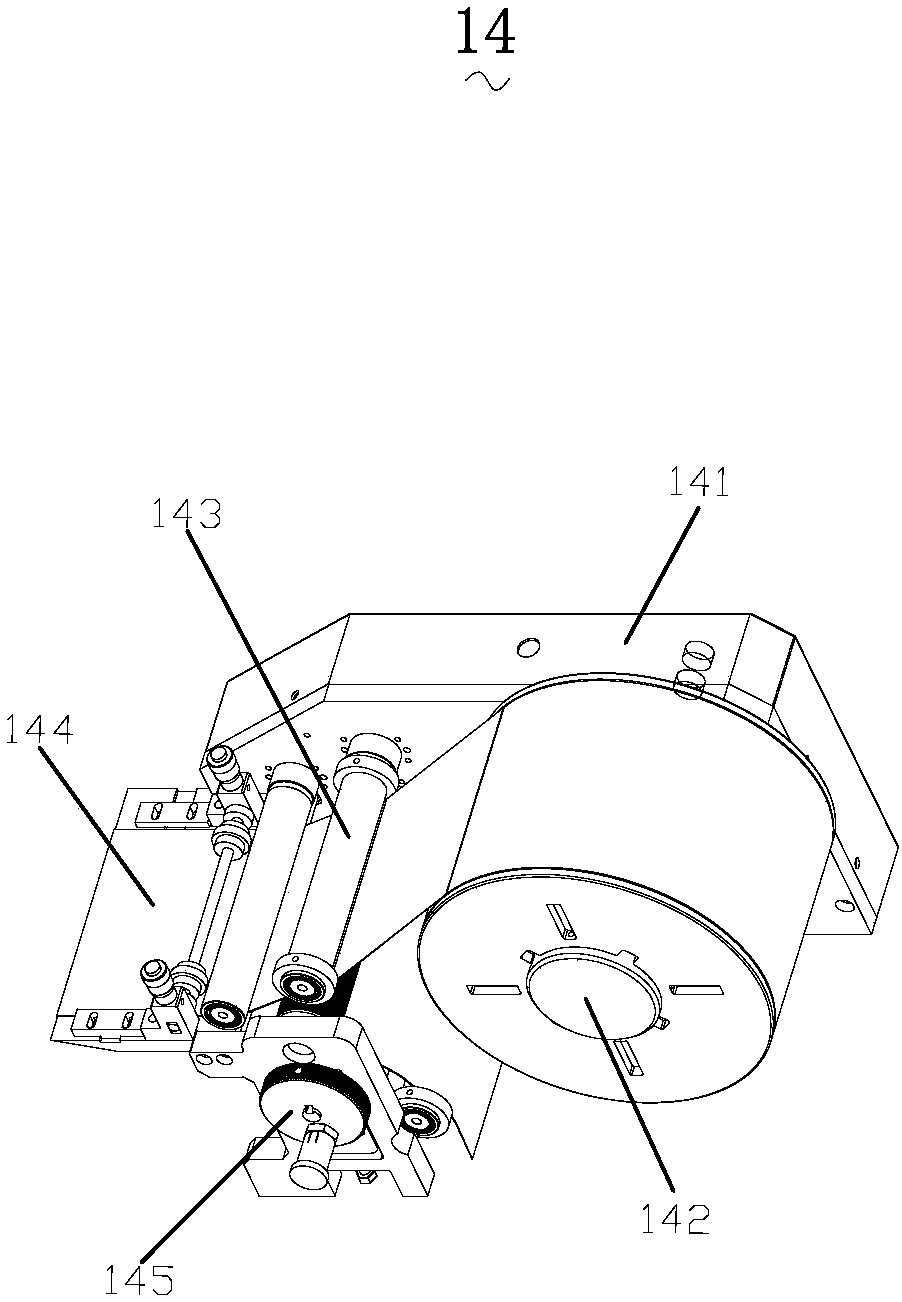

CCD adhesive attachment machine

ActiveCN106122203AImprove quality and efficiencyIncrease productivityMaterial gluingAdhesiveIndustrial engineering

The invention provides a CCD adhesive attachment machine which comprises a product conveying belt. A product locating platform is arranged on the product conveying belt. A CCD alignment platform and a plurality of adhesive piece feeding mechanisms are arranged on one side of the product locating platform. A four-axis linkage mechanical arm freely moving above the product conveying belt, the product locating platform, the CCD alignment platform and the multiple adhesive piece feeding mechanisms is arranged on the other side of the product locating platform. The product locating platform comprises two fixed check blocks and two movable check blocks. Each fixed check block and the corresponding movable check block are arranged in a relatively parallel manner. According to the CCD adhesive attachment machine, attachment operation of single-sided adhesives and double-sided adhesives of products of different sizes can be achieved only through one set of equipment, and attachment operation of single-sided adhesives and double-sided adhesives in different shapes and different sizes and at different positions can be achieved on the same product; product quality and production efficiency are greatly improved; normal operation of a machine table is operated only with one person; and production personnel are saved for enterprises well.

Owner:SHENZHEN WEIHONGKE TECH

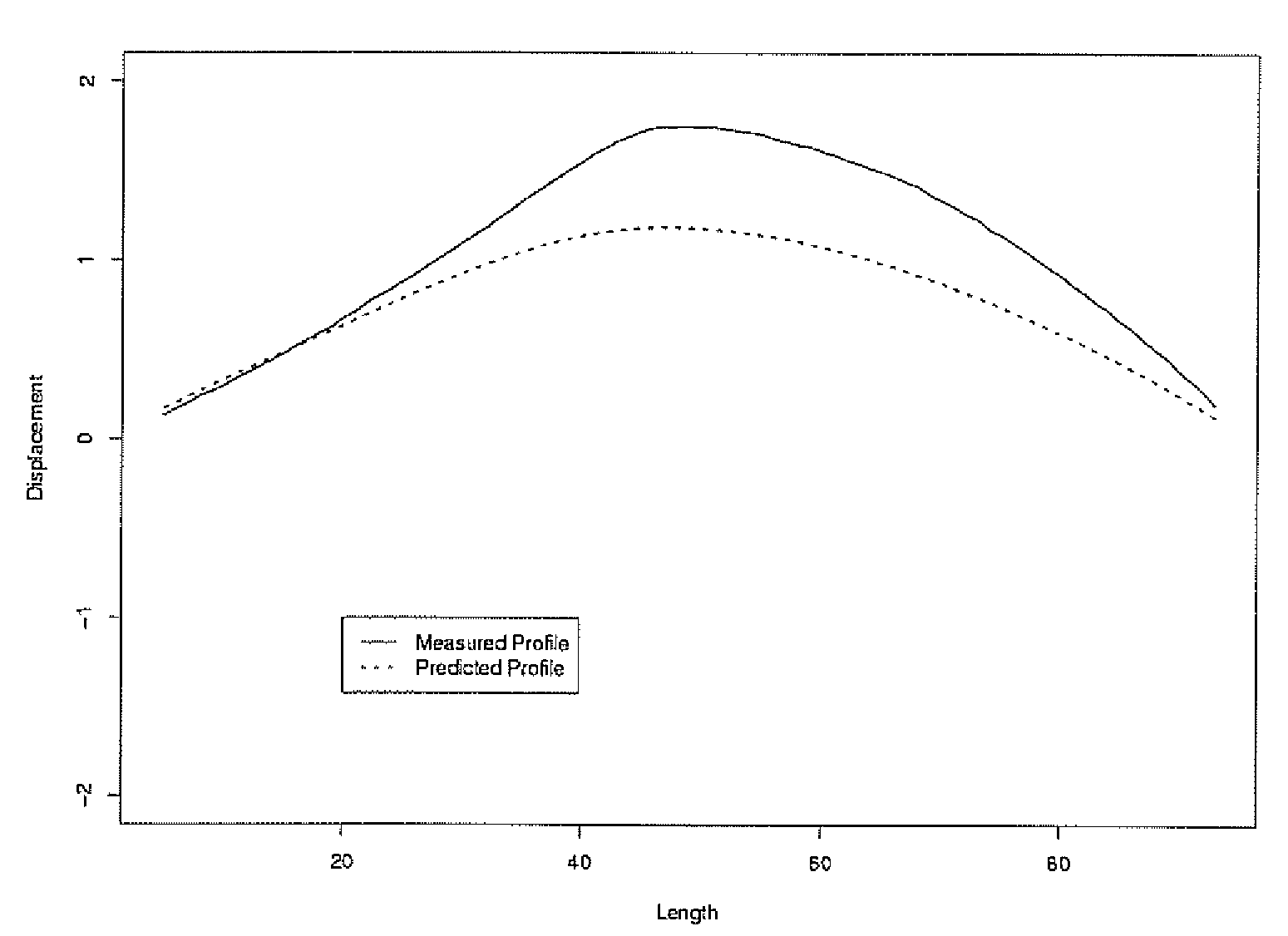

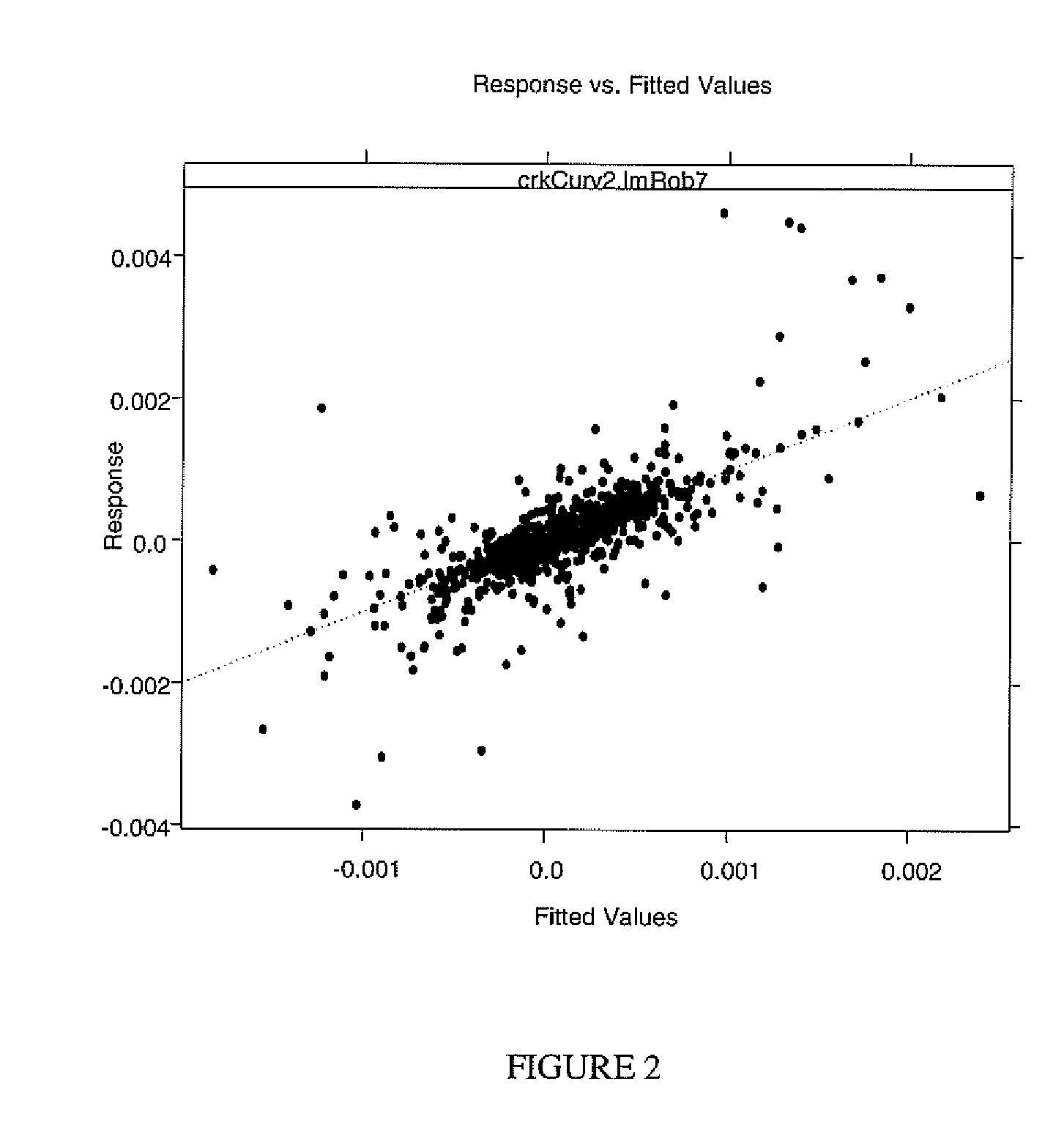

Methods for predicting dimensional stability of a wood product based on differential characteristics

Methods are provided for predicting warp of a wood product given its differential characteristics, such as, for example, curvature. The methods may involve measuring at least one original warp profile for each of one or more first wood products; measuring one or more inputs on the one or more first wood products; converting the warp profile, for each of the one or more first wood products, into a differential characteristic profile; developing a prediction algorithm based on the one or more inputs and the differential characteristic profile; measuring one or more inputs of the given wood product; inputting the one or more inputs of the given wood product into the prediction algorithm; and determining a differential characteristic profile for the given wood product based on the prediction algorithm.

Owner:WEYERHAEUSER NR CO

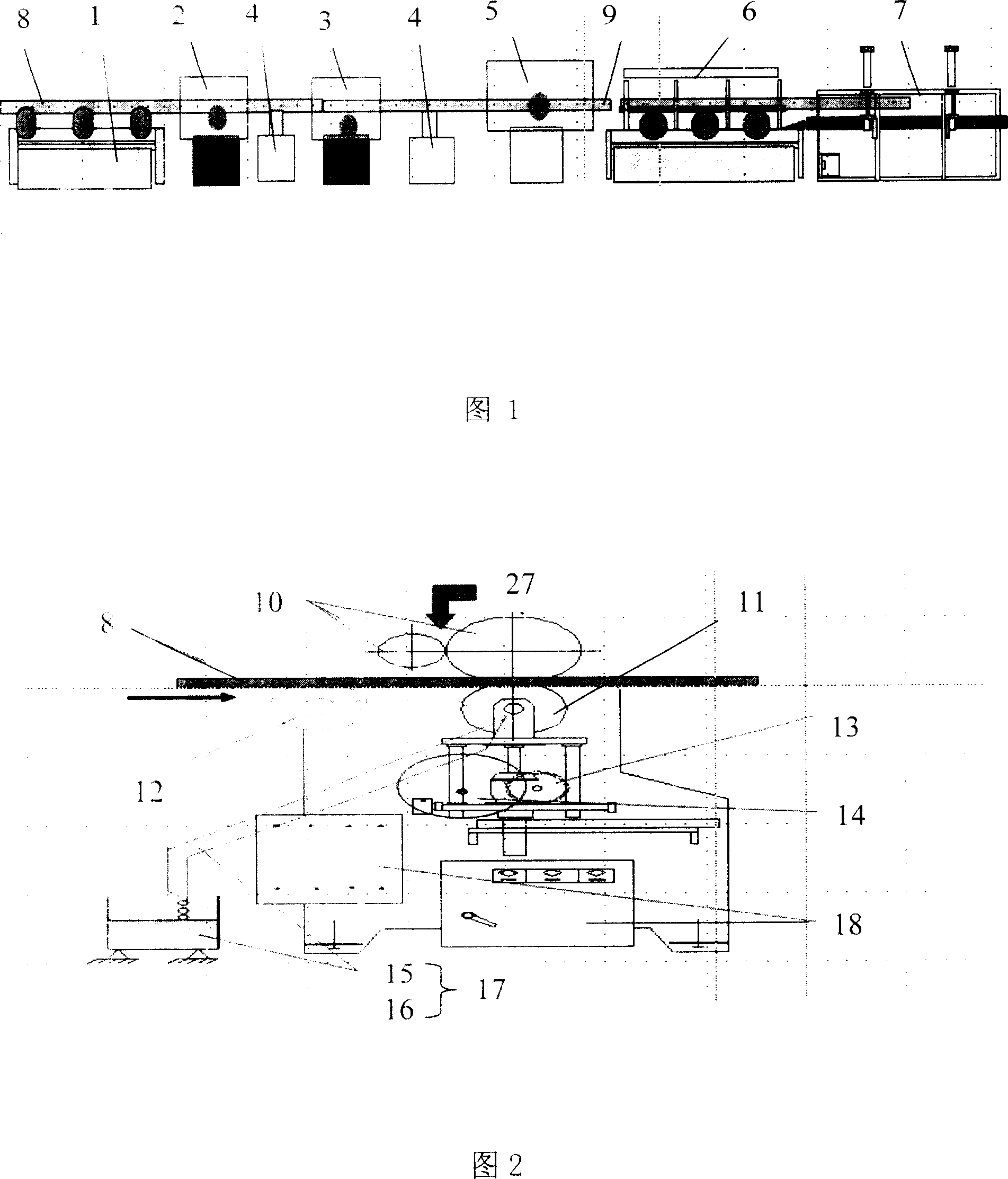

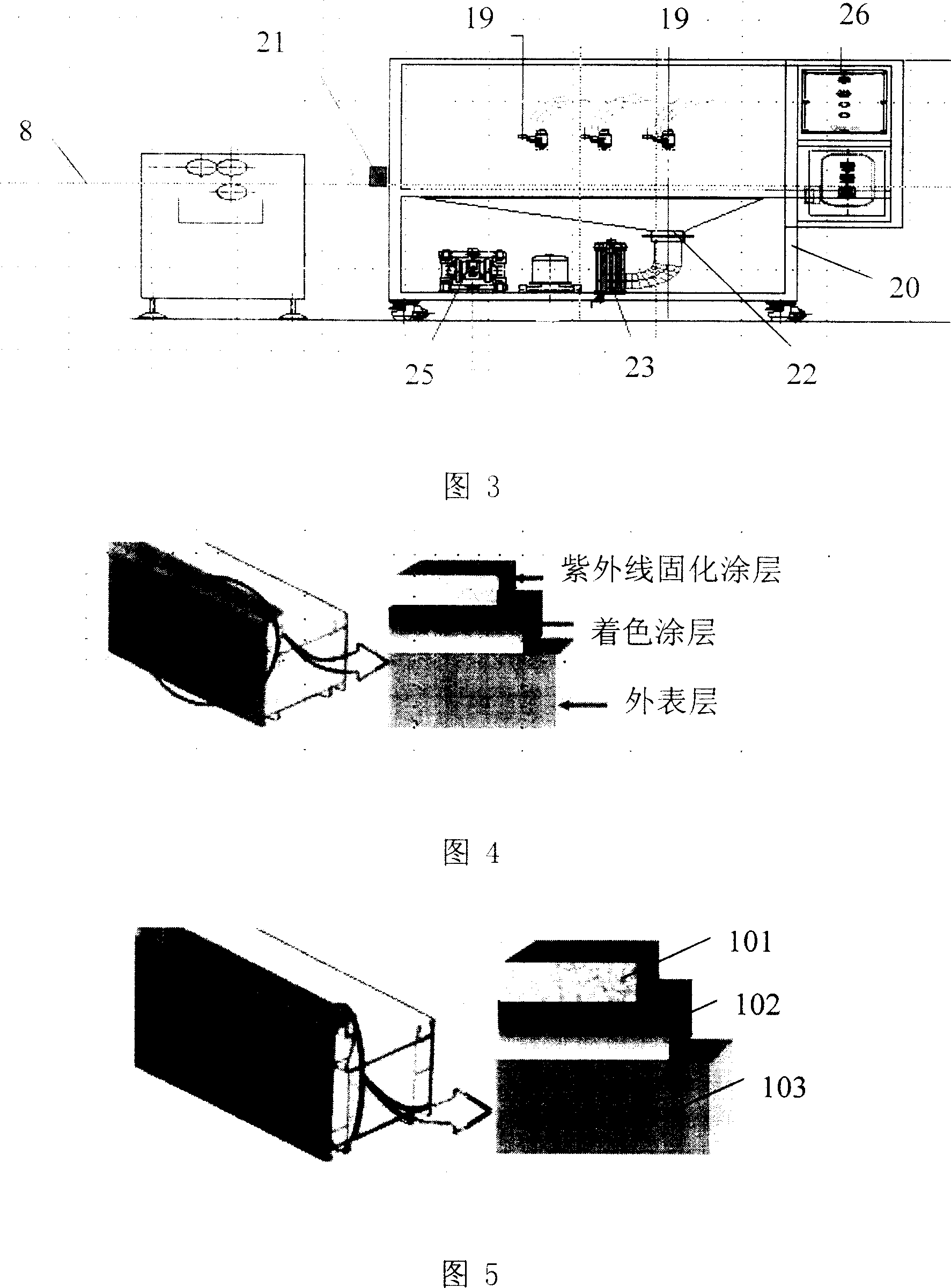

Synthetic resin window section bar having metal qualitative sense and surface coating equipment thereof

InactiveCN101082256AIncreased durabilityGood external aestheticsDoors/windowsCoatingsUV curingUltraviolet

The invention discloses the metallic synthetic resin window sectional material and its surface coater. It covers ultraviolet solidified coat on at least one exterior surface of the common synthetic resin window sectional material. It coats the thermosetting resin and the metallic ultraviolet solidified coating on the common synthetic resin window sectional material to achieve good endurance and external aesthetic while processing the windows. The surface coater provided by this invention can realize the continuous coating and solidifying on the surfaces of two or three dimension products, which can improve the working efficiency and extend its application range.

Owner:LG HAUSYS TIANJIN

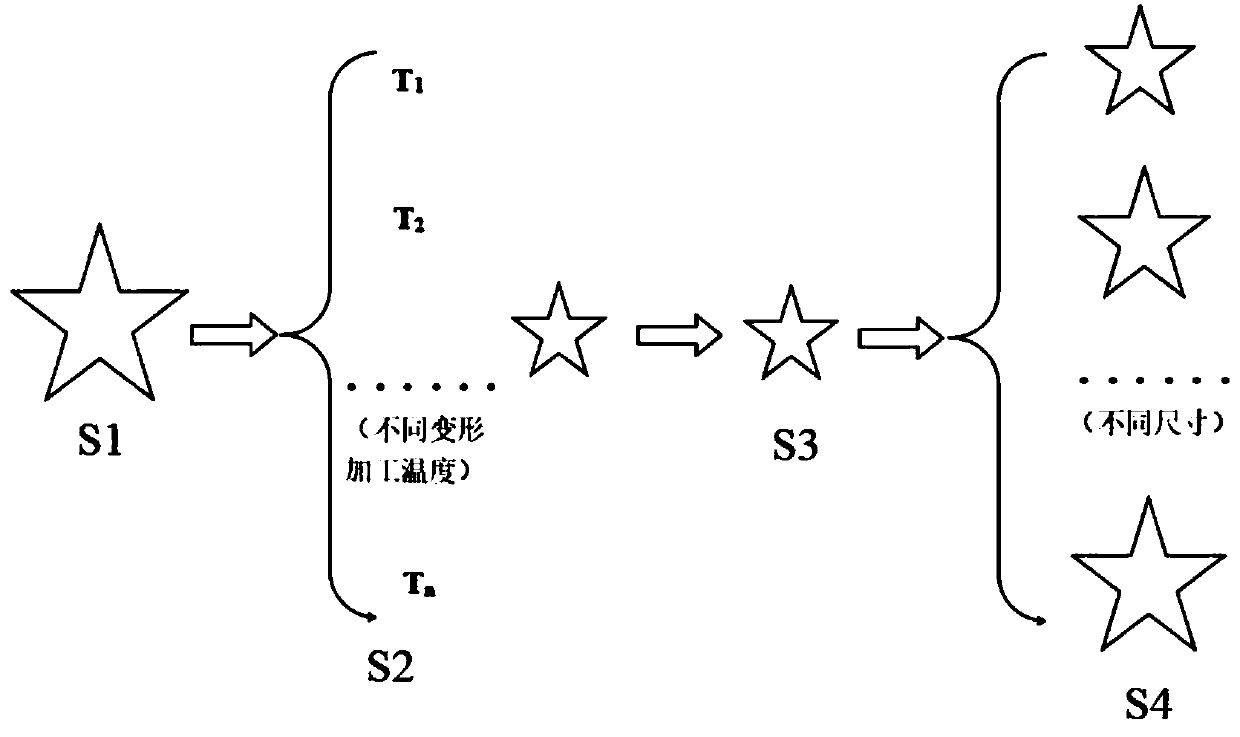

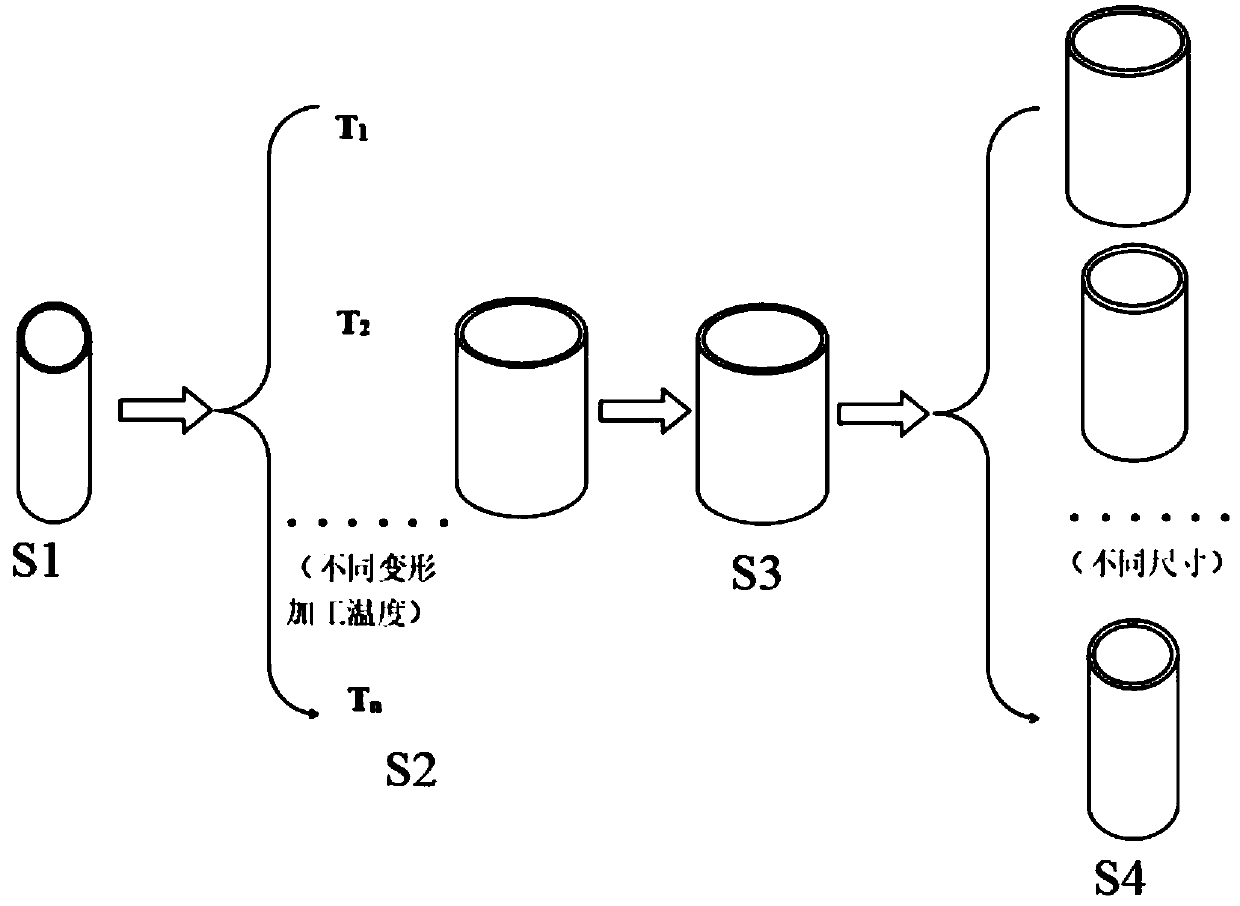

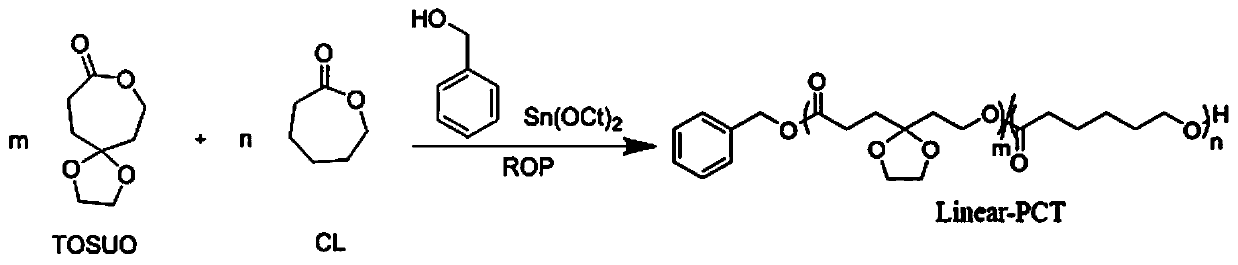

Processing method for preparing shape memory product

According to the scheme, the processing method for preparing a shape memory product comprises the following steps of 1, preparing an initial product with an initial shape by using a thermotropic shapememory polymer material according to a conventional processing method; 2, adjusting the deformation machining temperature according to the size requirement after recovery, deforming the initial product continuously at the temperature till the deformed shape meets the preset requirement, cooling, and obtaining a temporary shape product; and 3, heating the installed temporary shape product, and generating different deformations after the temporary shape product returns from the deformed shape to the initial shape so as to obtain preset shape memory products with different sizes. The invention provides a simple processing method for preparing products with different sizes, which only needs to control the deformation processing temperature and does not need multi-size molds or modeling design. The preparation method is suitable for the thermotropic shape memory polymer with crystallinity and has universality, and the prepared product is particularly suitable for special conditions of larger space range or shape difference during installation and use.

Owner:SUN YAT SEN UNIV

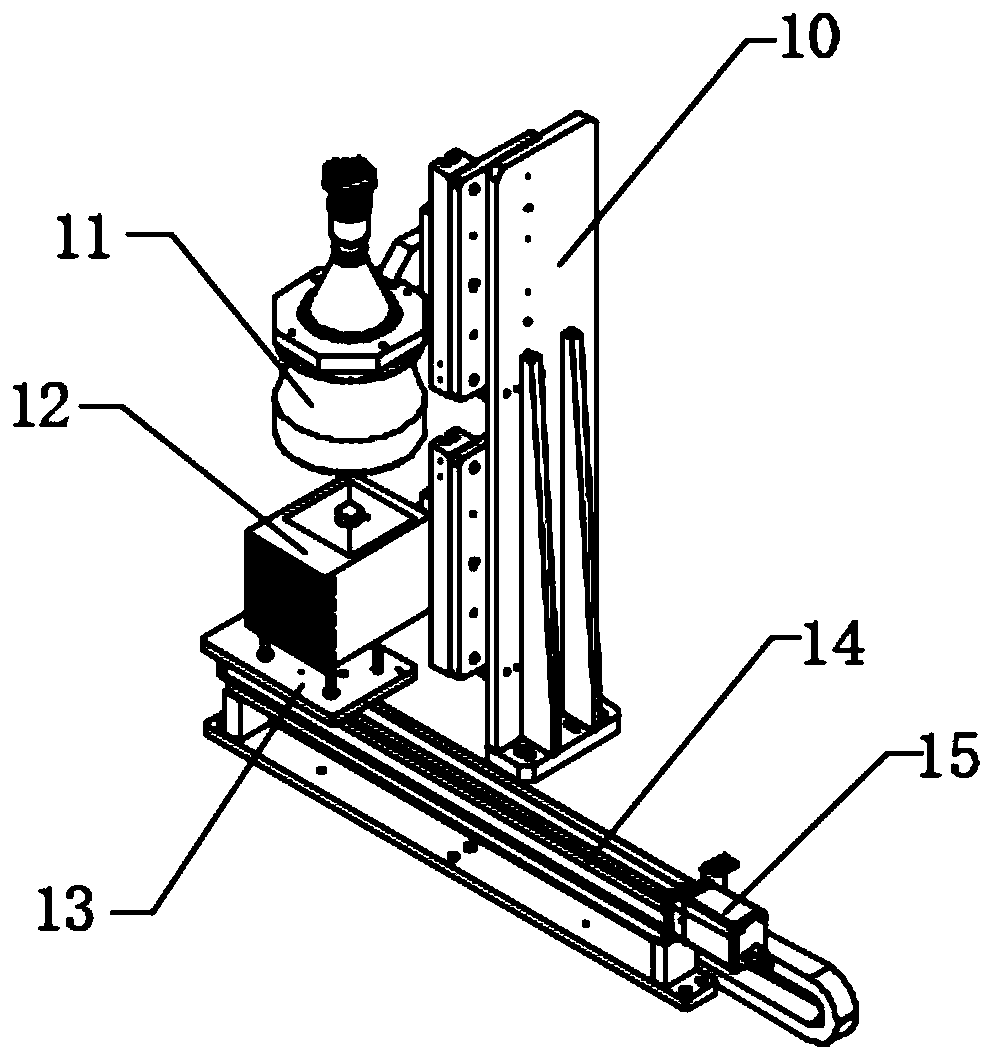

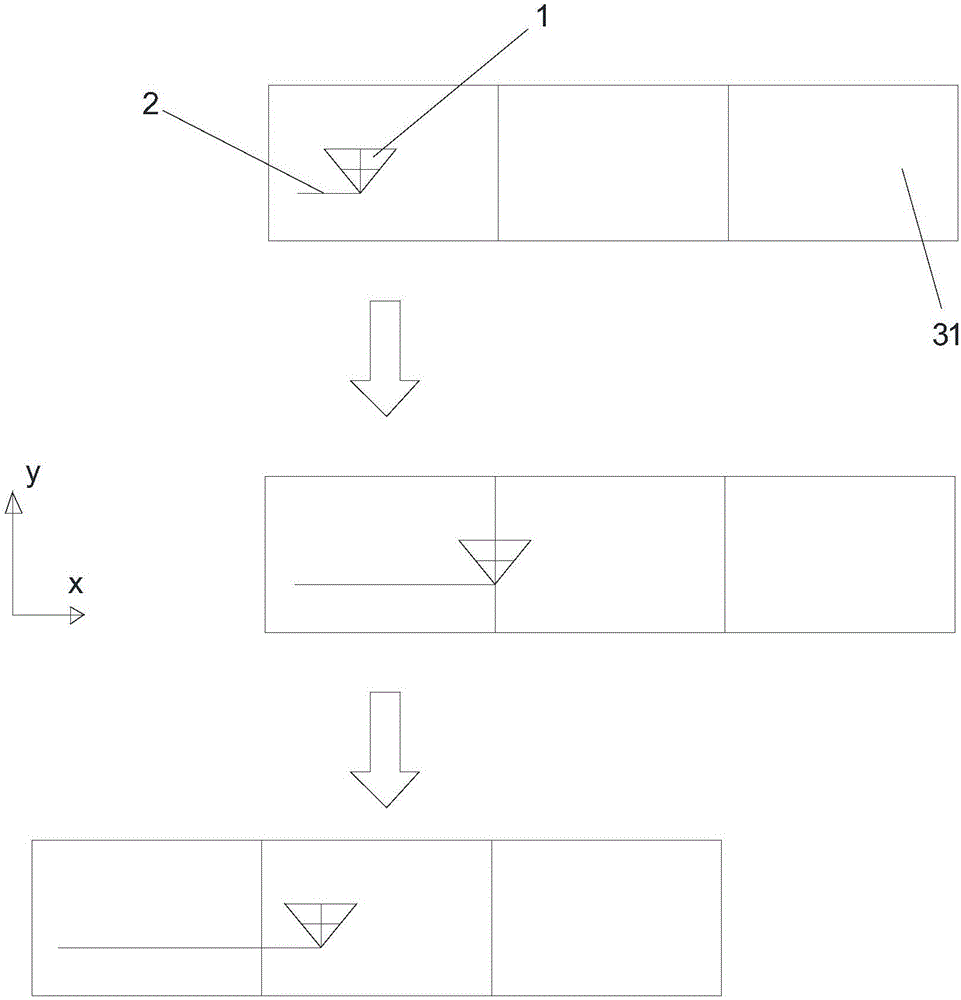

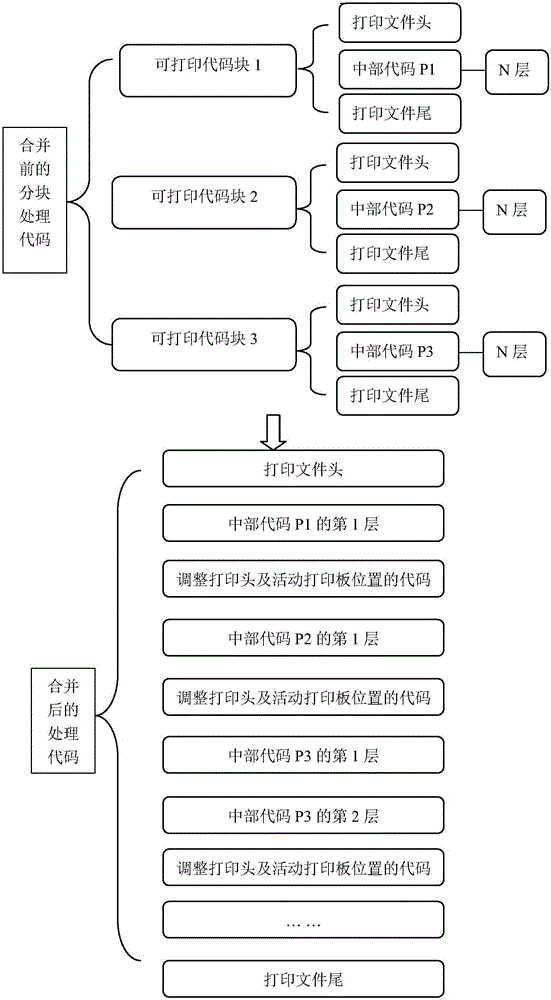

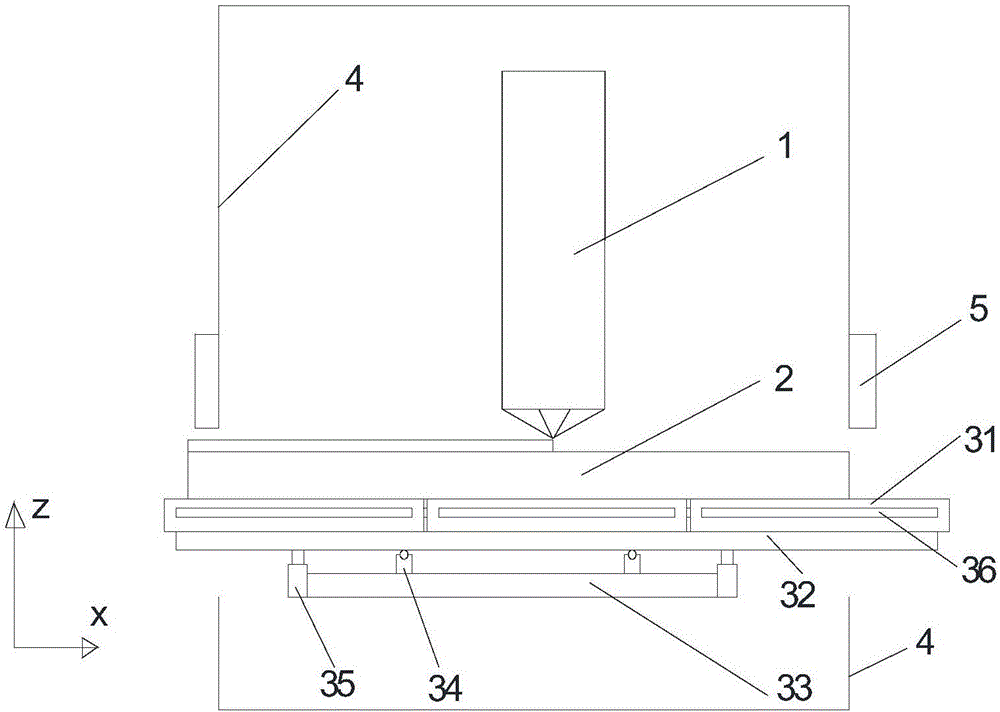

3D printing method and device for one-way large-dimension products

ActiveCN106584840AEasy to use and flexibleFlexible temperature controlManufacturing driving means3D object support structuresEffective solutionEngineering

The invention discloses a 3D printing method and device for one-way large-dimension products. Special treatment is conducted on codes which are formed after a model of the products to be printed is subjected to segmentation processing, the situation that a printing head and a printing base readjust the printing position automatically in the printing process can be achieved, and accordingly the printing range is ensured. The printing base is of a combined structure, and movable printing plates can be freely connected and spliced so as to form the integrated printing base meeting the one-way dimensional requirement finally. The printing base can cooperate with the printing head in the printing process to realize automatic shifting of the movable printing plates. By means of the 3D printing method and device for the one-way large-dimension products, the problem that the one-way printing dimension of existing 3D printing equipment is limited is solved, automatic integrated 3D printing of the one-way large-dimension products is achieved, the performance and dimension precision of the large-scale products are ensured accordingly, and a quick and effective solution is provided for manufacturing of one-way large-dimension parts in various fields.

Owner:JIANGSU UNIV OF SCI & TECH

Parallel iterative decoding method for product code

InactiveCN1688111AReduce bit error rateCode conversionError correction/detection by combining multiple code structuresCoding decodingComputer science

This invention relates to a parallel iteration decode method for product codes in a communication field, which selects a method of decoding in all dimension directions simultaneously or alternately decoding in time division at all dimensional directions or partly decoding simultaneously partly decoding alternately in time division according to the proportion of the number of the sub-codes decoders and dimension numbers of the product codes including: N sub-code decoders carry out sub-code decoding at N directions of N dimensional product codes simultaneously, or one decoder decodes at N directions of N dimension product codes alternately in time division, which can start from any dimensional direction of the N dimensions, or when the number of the decoders M is smaller then M, M is smaller than N, they work at the same time or partly work to finish the decode at N directions of N dimension product codes.

Owner:SHANGHAI JIAO TONG UNIV

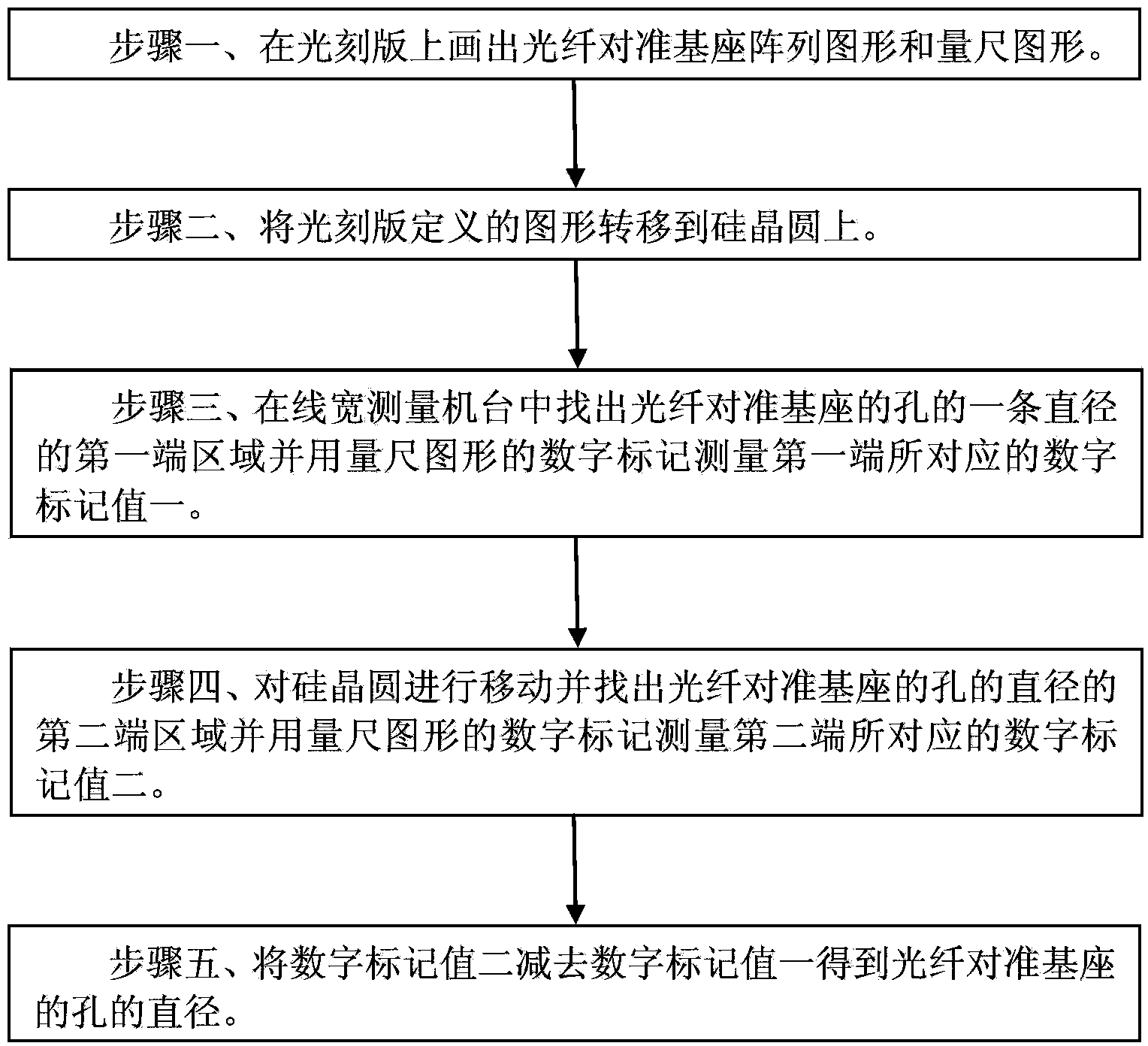

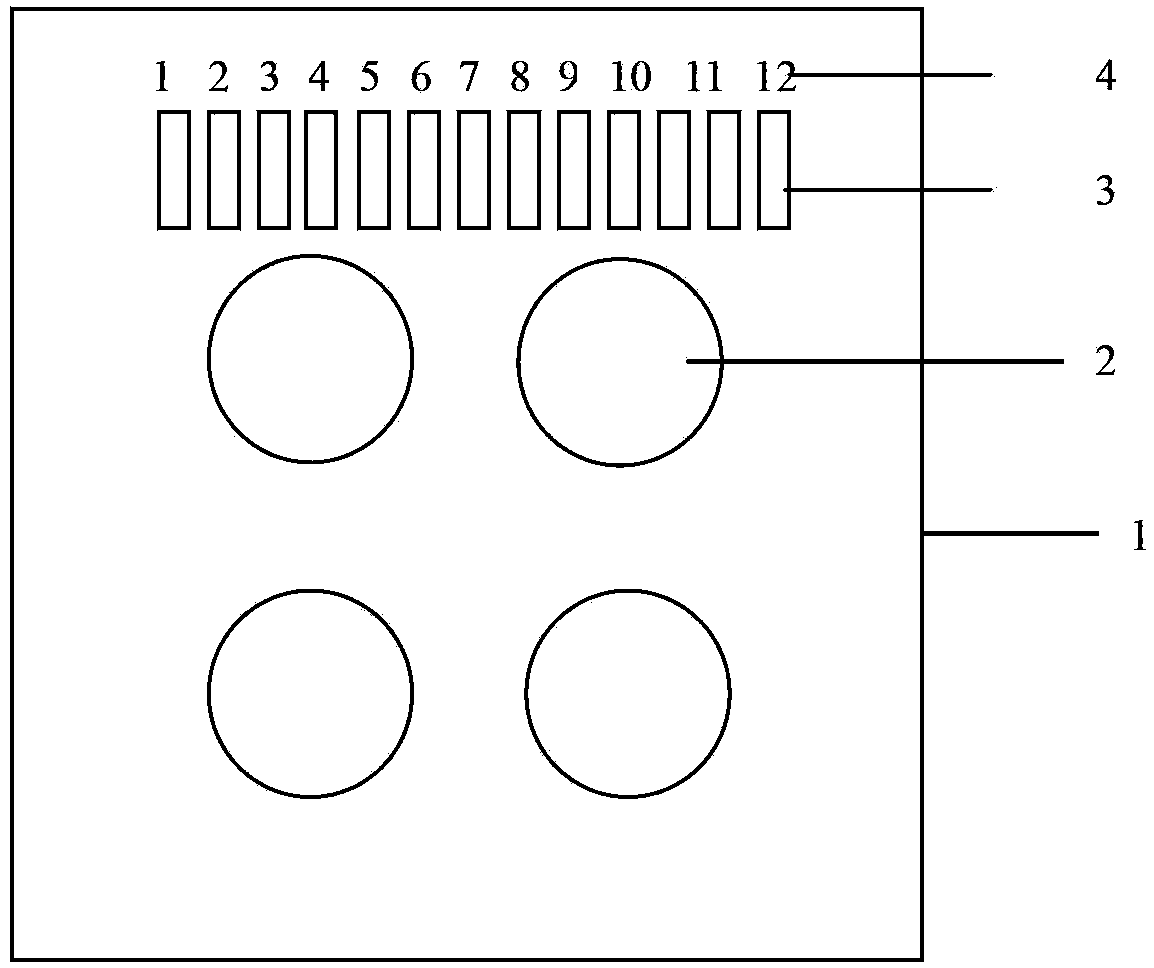

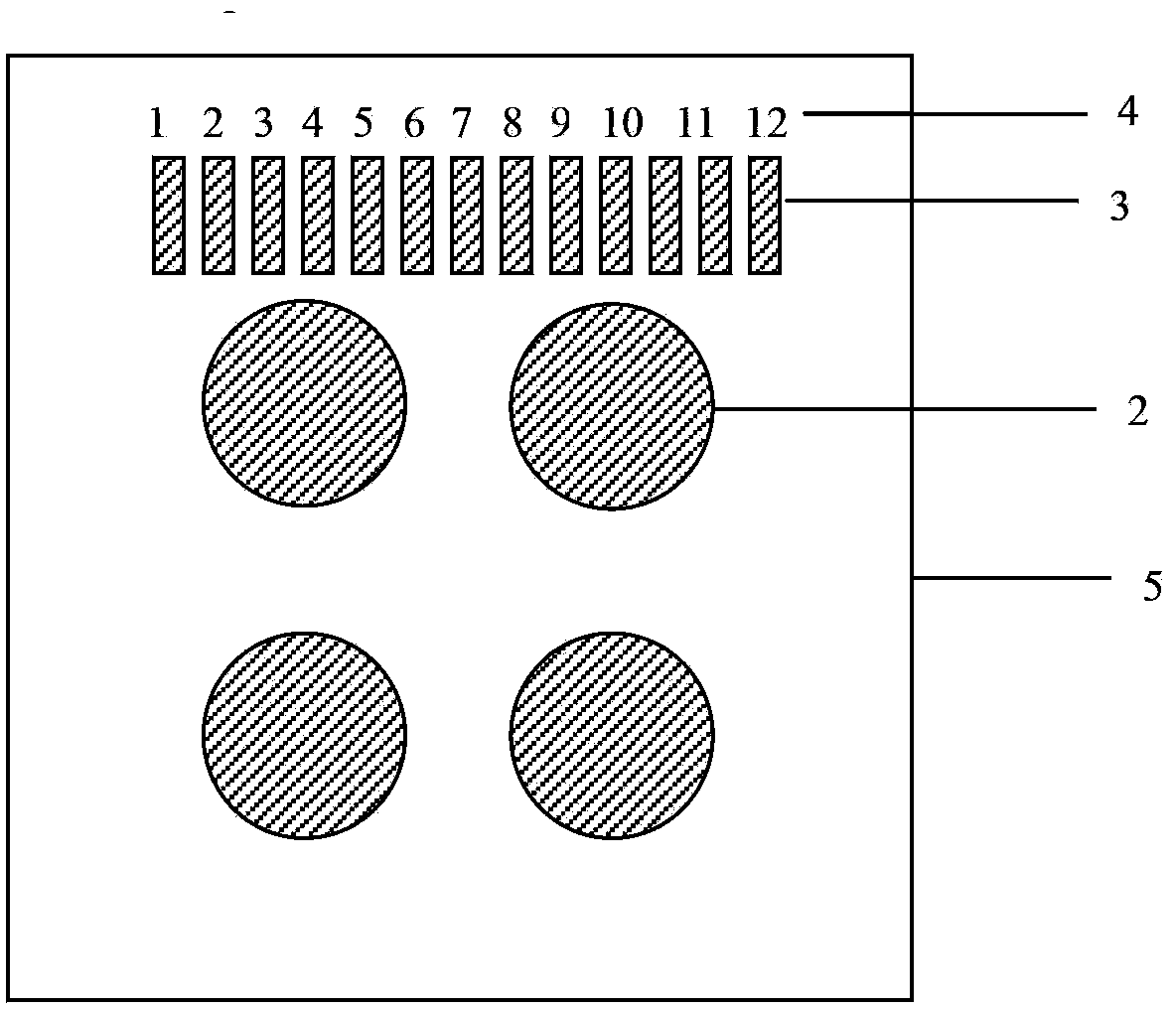

Online measuring method used during optical fiber alignment base array manufacturing with silicon substrate technology

ActiveCN103852044AHigh measurement accuracyRealize high-precision online line width monitoringMeasurement devicesPhotomechanical apparatusLine widthMeasurement precision

The invention discloses an online measuring method used during optical fiber alignment base array manufacturing with the silicon substrate technology. The method comprises the steps of manufacturing a photolithography mask, manufacturing a measuring scale graph beside a hole of the graph of an optical fiber alignment base array, setting the line width of each line of the measuring scale graph to be smaller than the size of the hole of the graph of the optical fiber alignment base array by two orders of magnitudes, and making the line width and intervals of the lines of the measuring scale graph unchanged; transferring the graph of the photolithography mask to a silicon wafer; measuring a first numerical flag value corresponding to the first end of the hole of the optical fiber alignment base with numerical flags of the measuring scale graph in a line width measuring machine table; measuring a second numerical flag value corresponding to the second end of the hole of the optical fiber alignment base with numerical flags of the measuring scale graph in the line width measuring machine table; obtaining the diameter of the hole of the optical fiber alignment base based on the difference between the first numerical flag value and the second numerical flag value. According to the method, the measurement accuracy of the size of the optical fiber alignment base array can be improved by two orders of magnitudes, and high-accuracy online line width measurement of large products can be achieved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

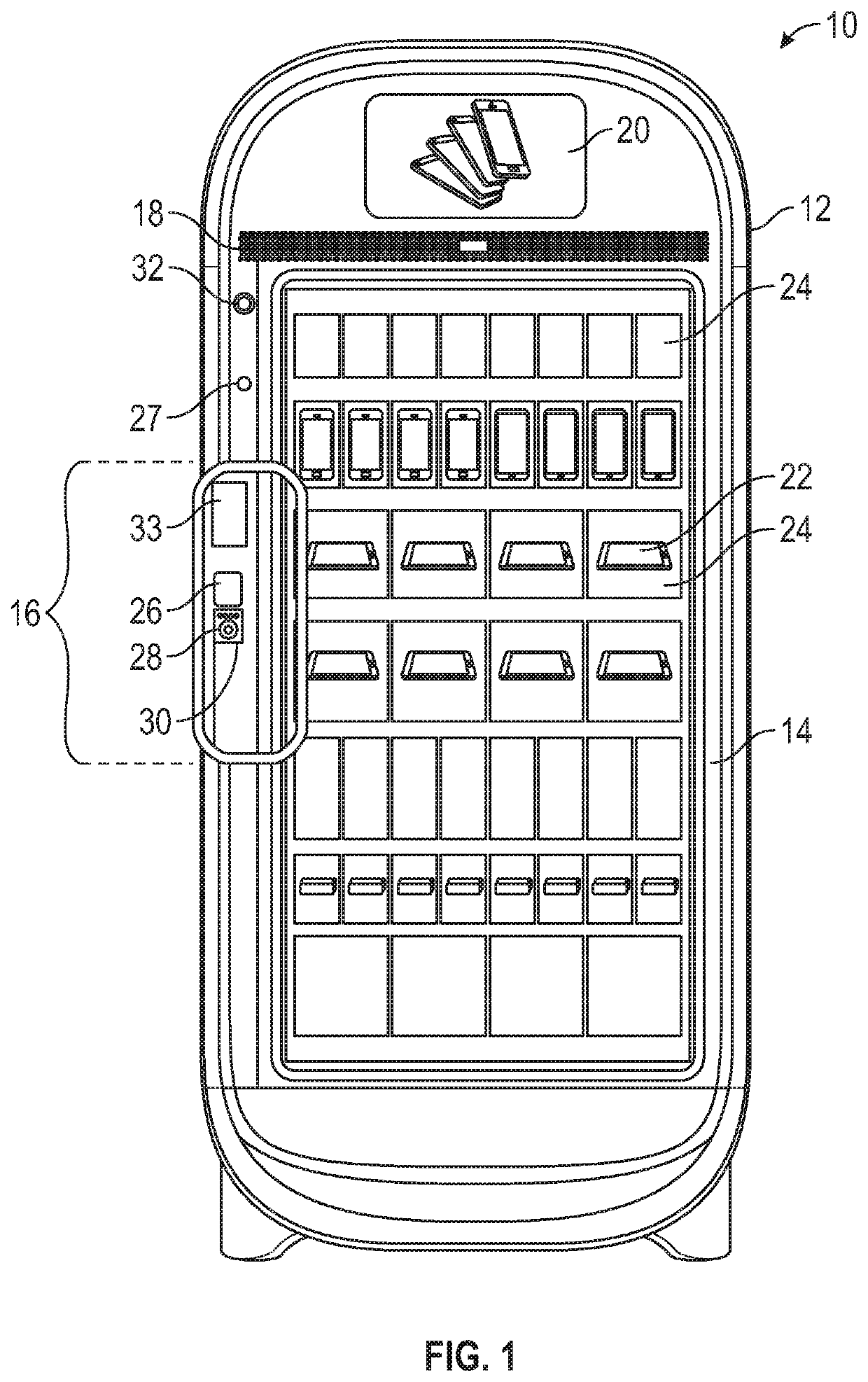

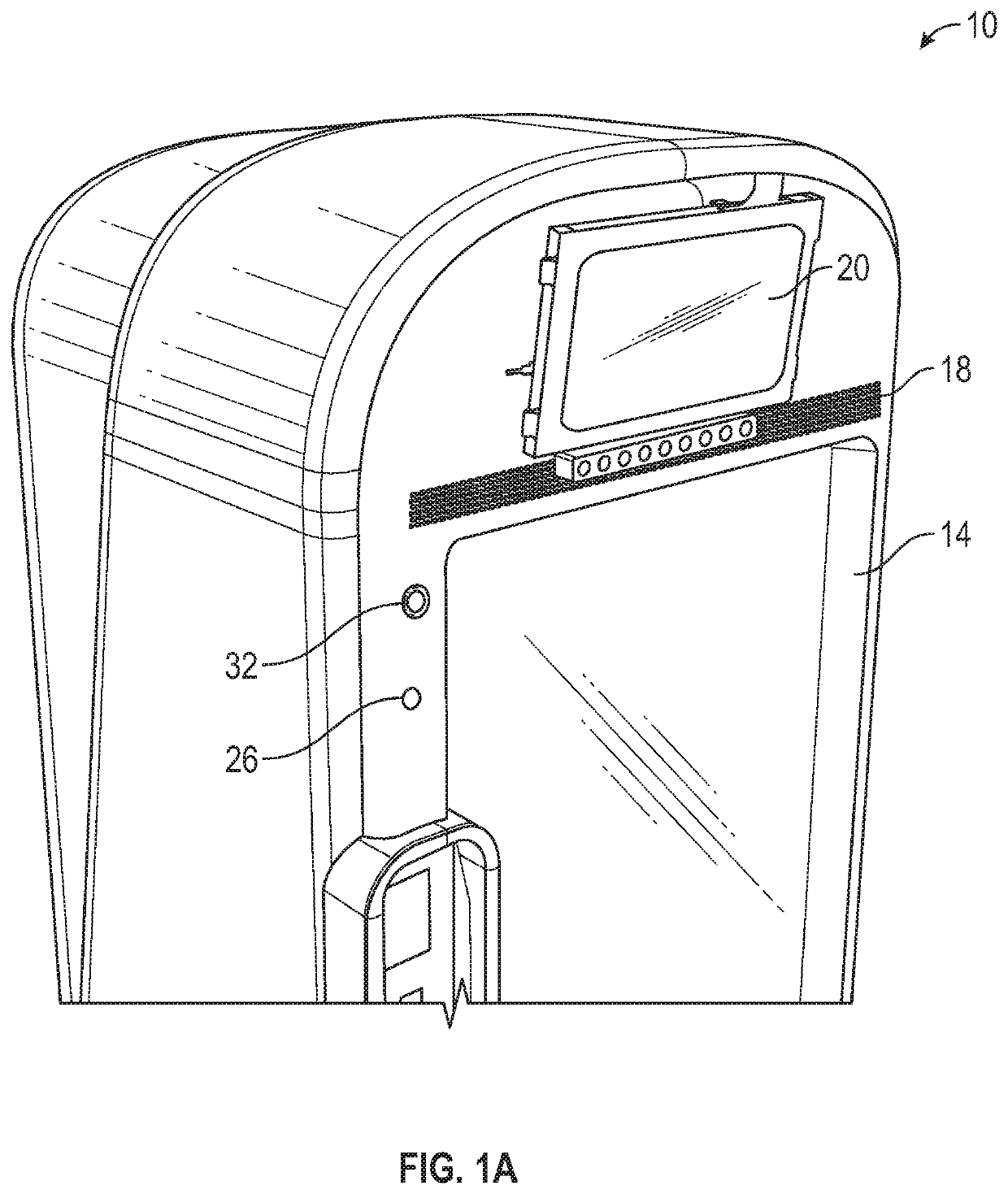

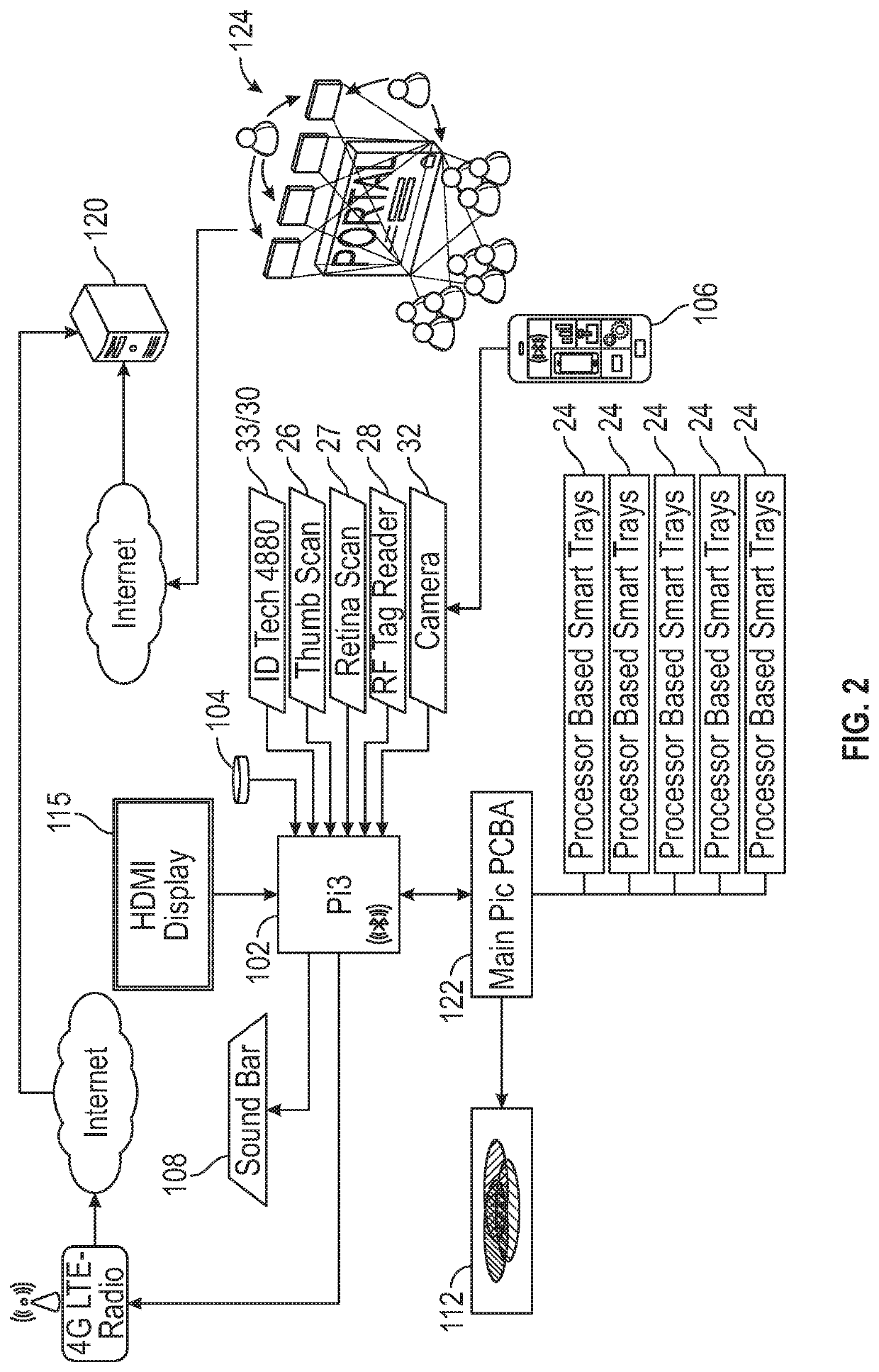

System and method of individualized merchandising in an automatic retail device

A system and method of stocking an automatic retail device including receiving seller identification information of a seller including financial institution information of the seller, receiving proposed product information of a product to be offered for sale by the seller, assigning a lease space in the automatic retail device for stocking of the product, determining whether the assigned leased space in the automatic retail device is available, acquiring product information of the product using the automatic retail device, and indicating a location of the leased space in the automatic retail device for stocking the product. The proposed information of the product may include a description of the product, a size of the product, or a weight of the product. The acquired product information may include an image of the product or a weight of the product.

Owner:VIATOUCH MEDIA INC

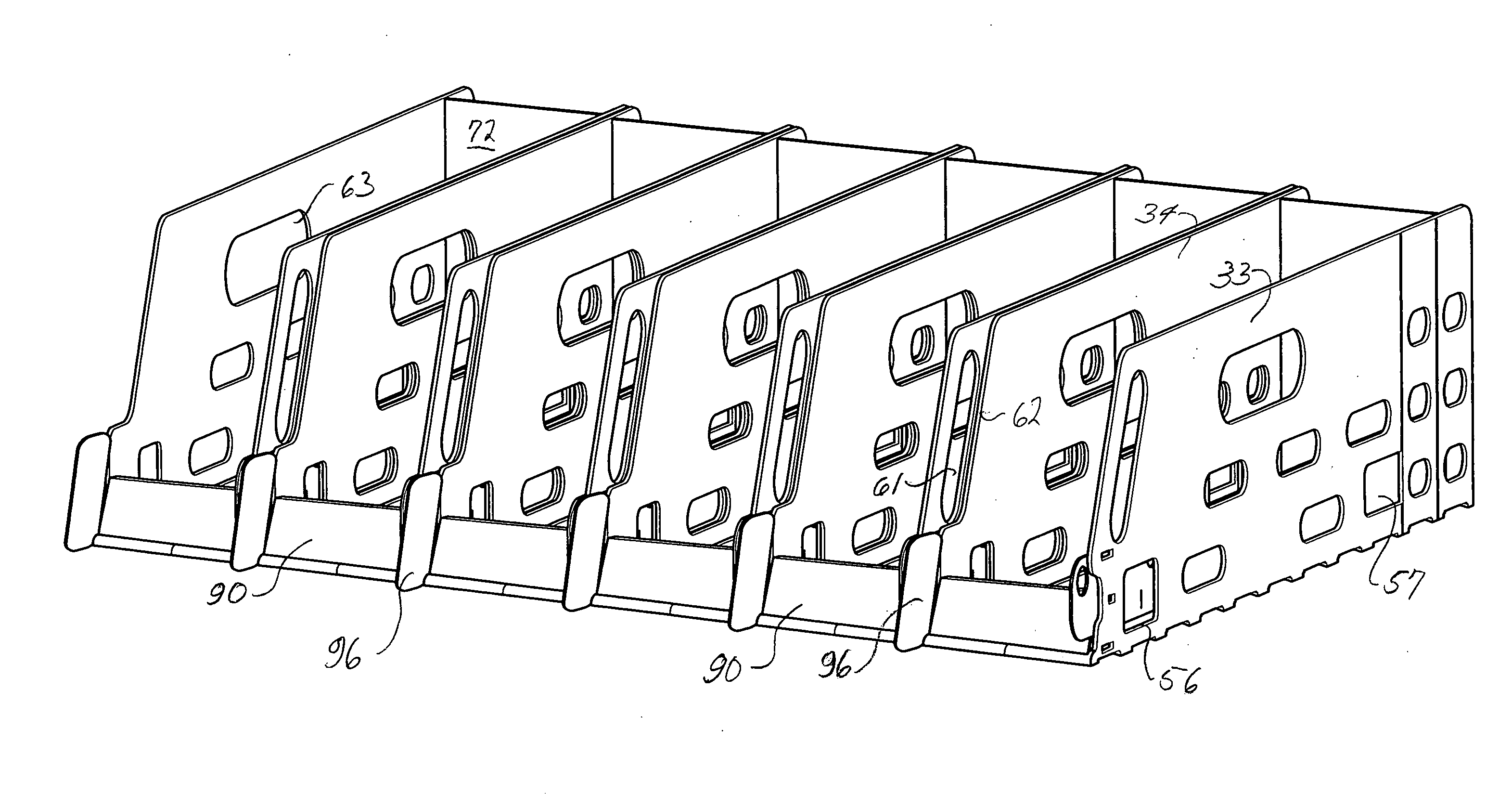

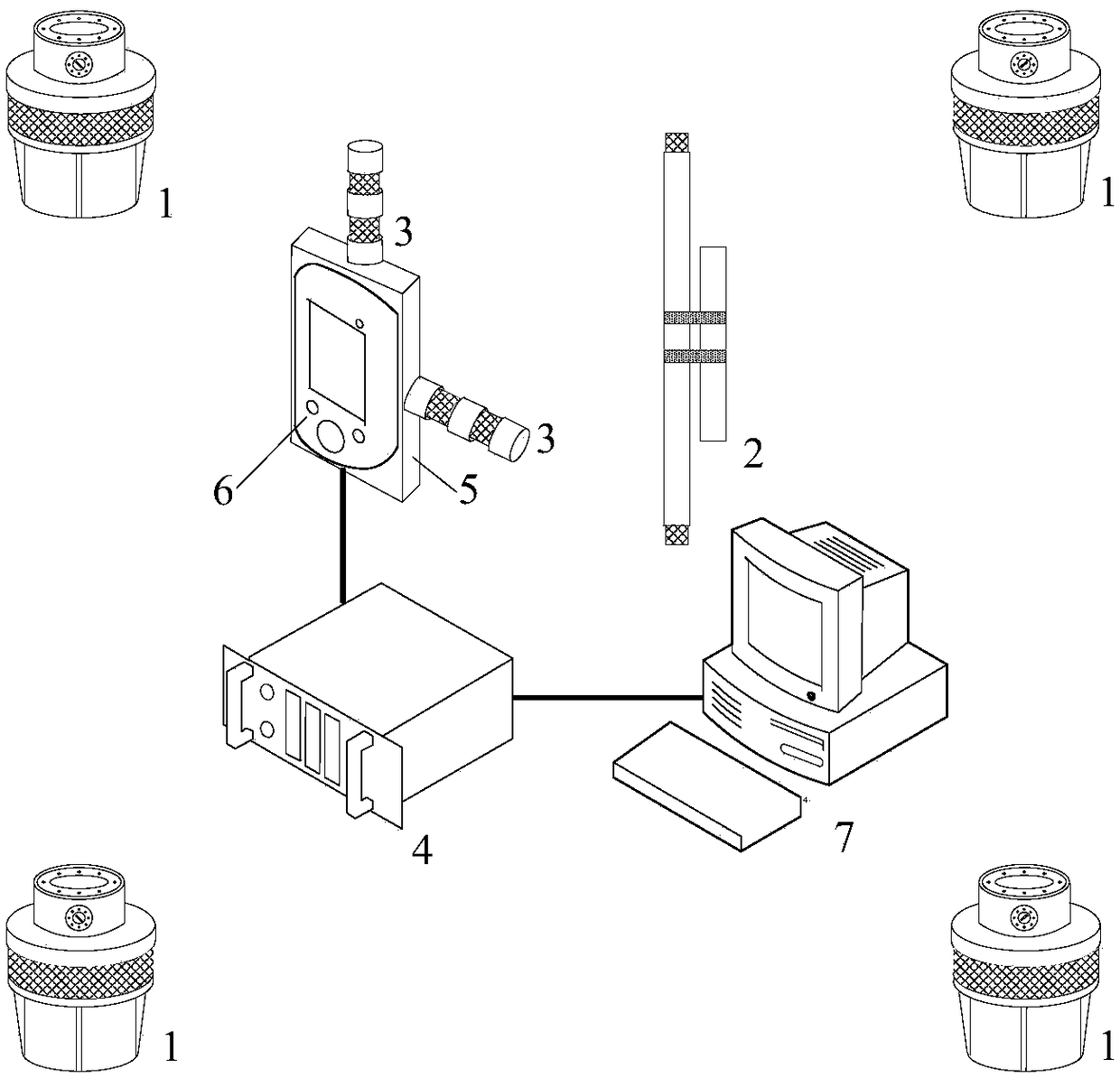

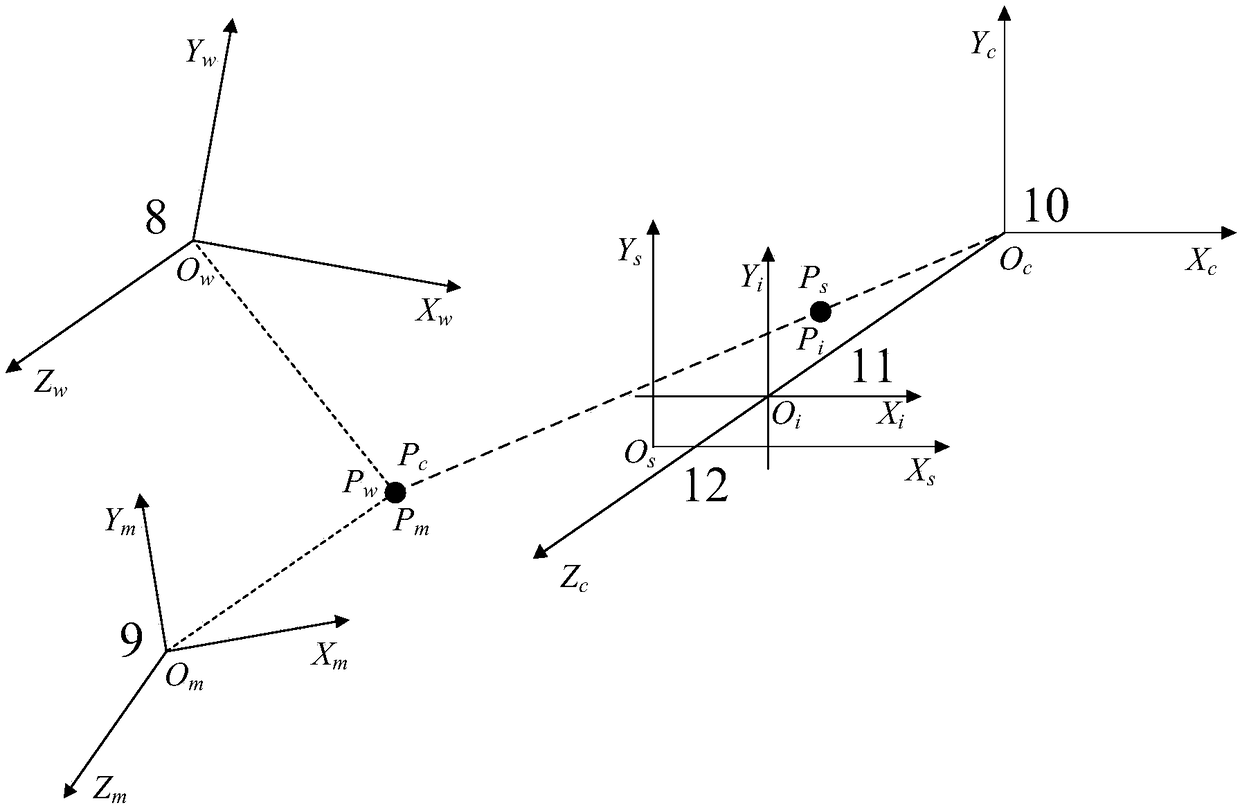

A panoramic three-dimensional registration system and method for augmented reality assembly

ActiveCN109345633AAccurate identification and registrationRealize panoramic accurate 3D registrationImage data processingVisual field lossWorkstation

The present invention relates to a panoramic three-dimensional registration system and method for augmented reality assembly, belonging to the field of augmented reality technology, and solves the problems of high registration error rate, small application environment size, high lighting requirement, high calculation amount of algorithm and low positioning accuracy in the prior art. Includes an iGPS transmitter for emitting a sector laser; IGPS reference ruler for calibrating the surveying coordinate system; An iGPS vector sensor for receiving a laser signal emitted from the transmitter; An iGPS workstation for obtaining coordinates of laser signal receiving points in an iGPS vector sensor; An imaging terminal for acquiring a realistic scene image; A calculation and display terminal is configured to perform coordinate transformation on the virtual information and superimpose the virtual information on a real scene image. The invention can realize panoramic three-dimensional registration of products of all sizes, visual field angles and any lighting environment without feature recognition. At the same time, the algorithm has low computational complexity and 0.2 mm positioning accuracy, which can be applied to the accurate display of augmented reality assembly process.

Owner:BEIJING MECHANICAL EQUIP INST

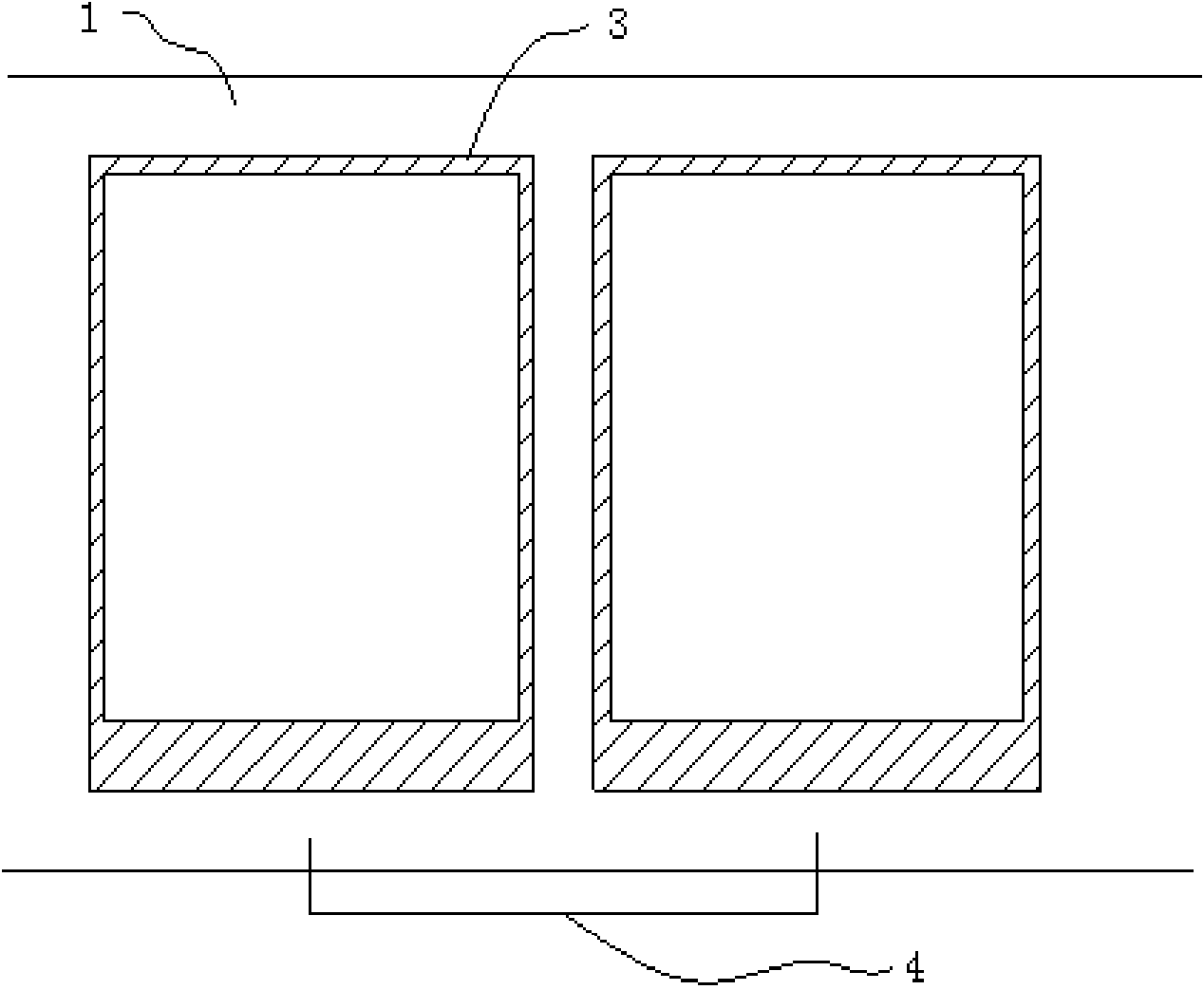

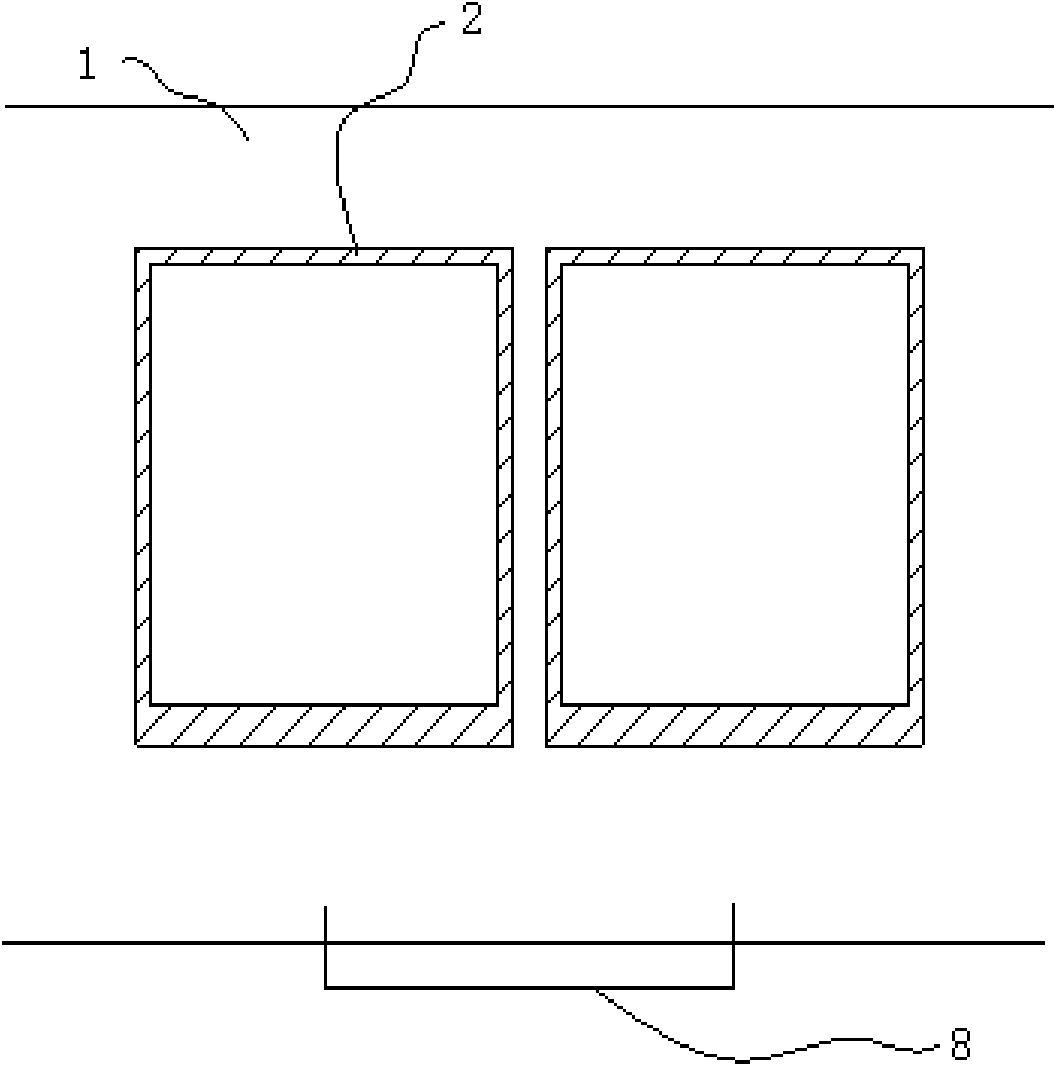

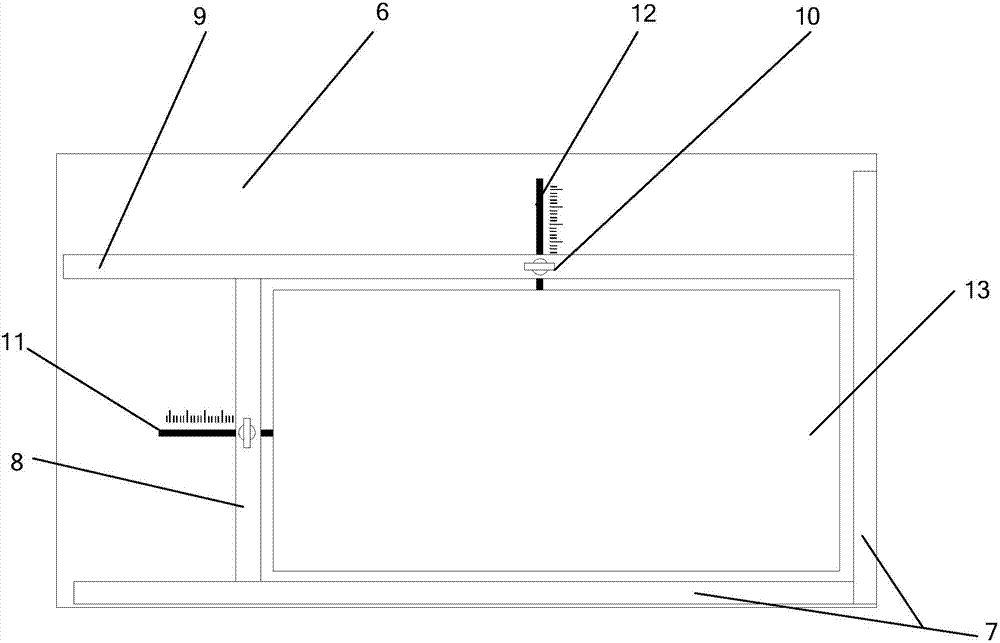

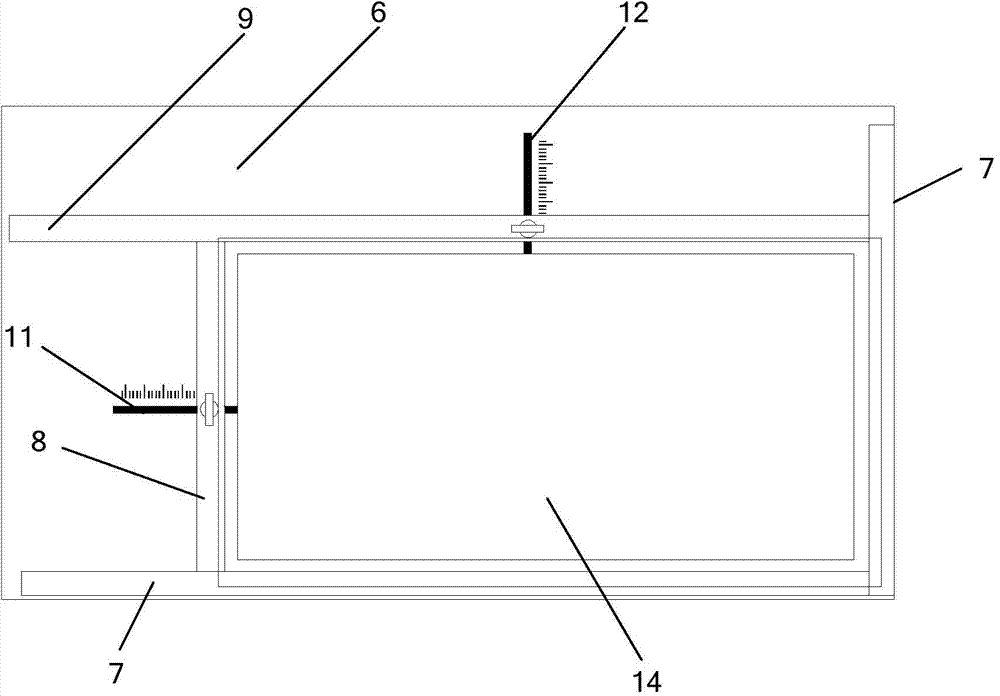

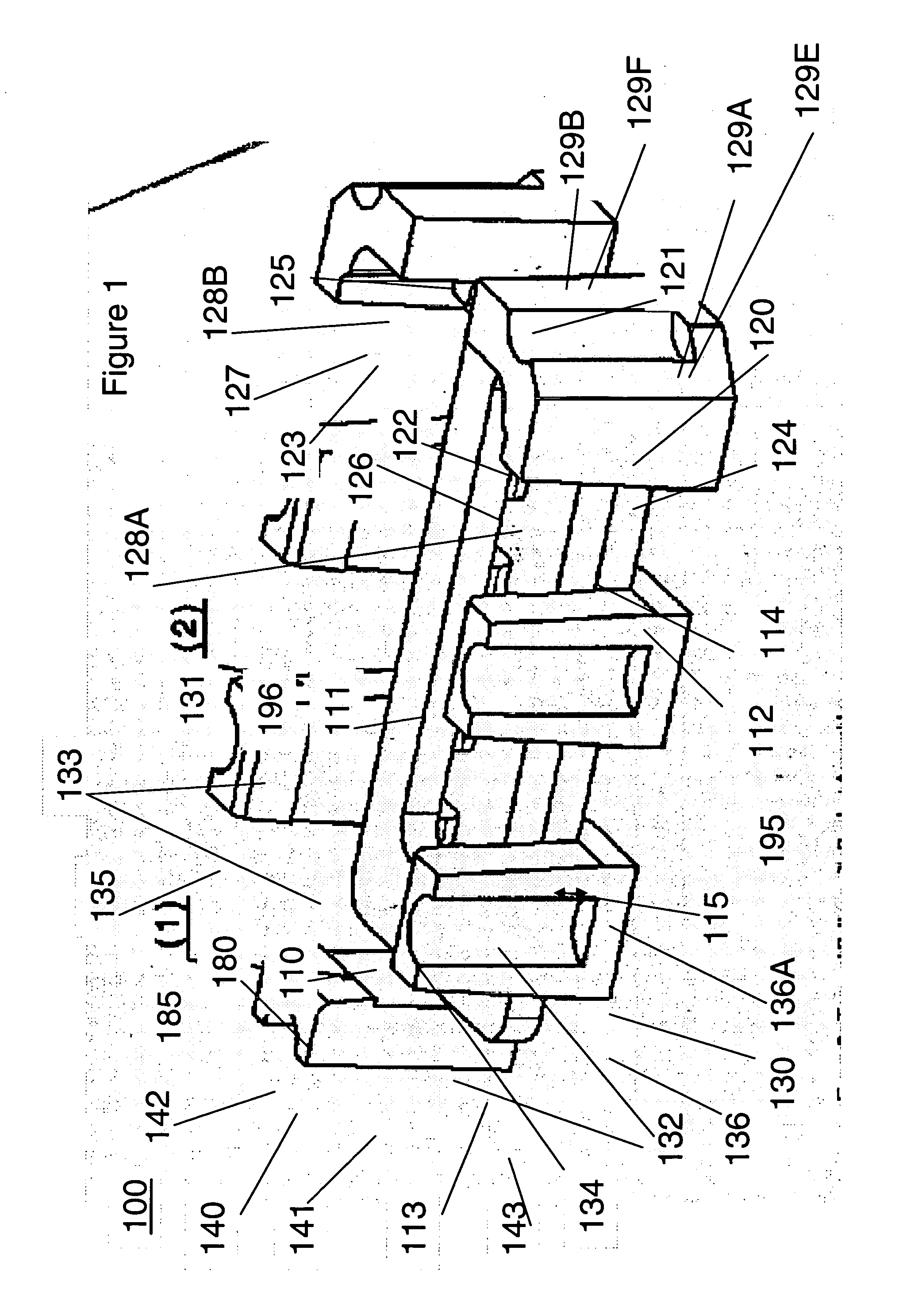

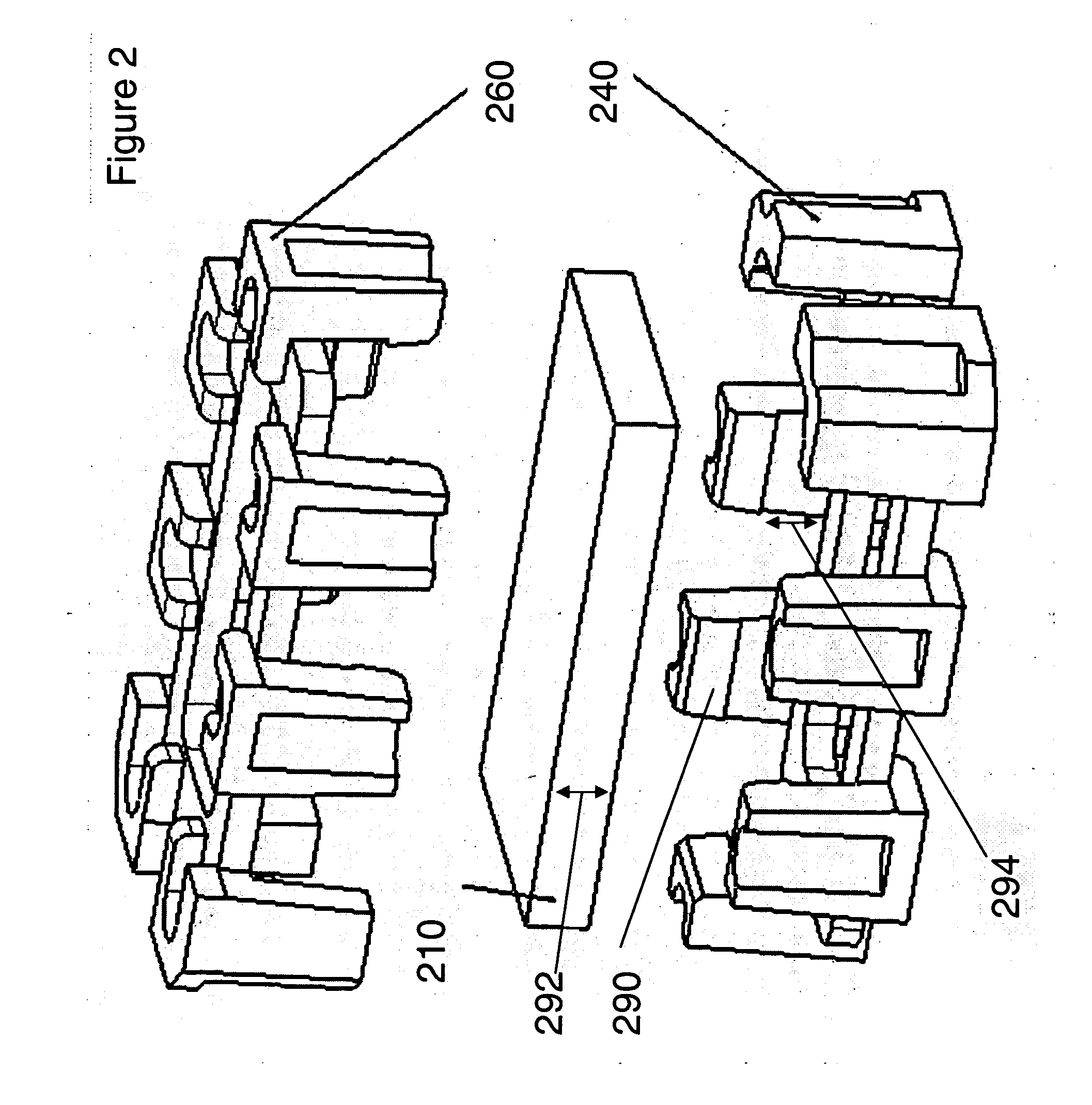

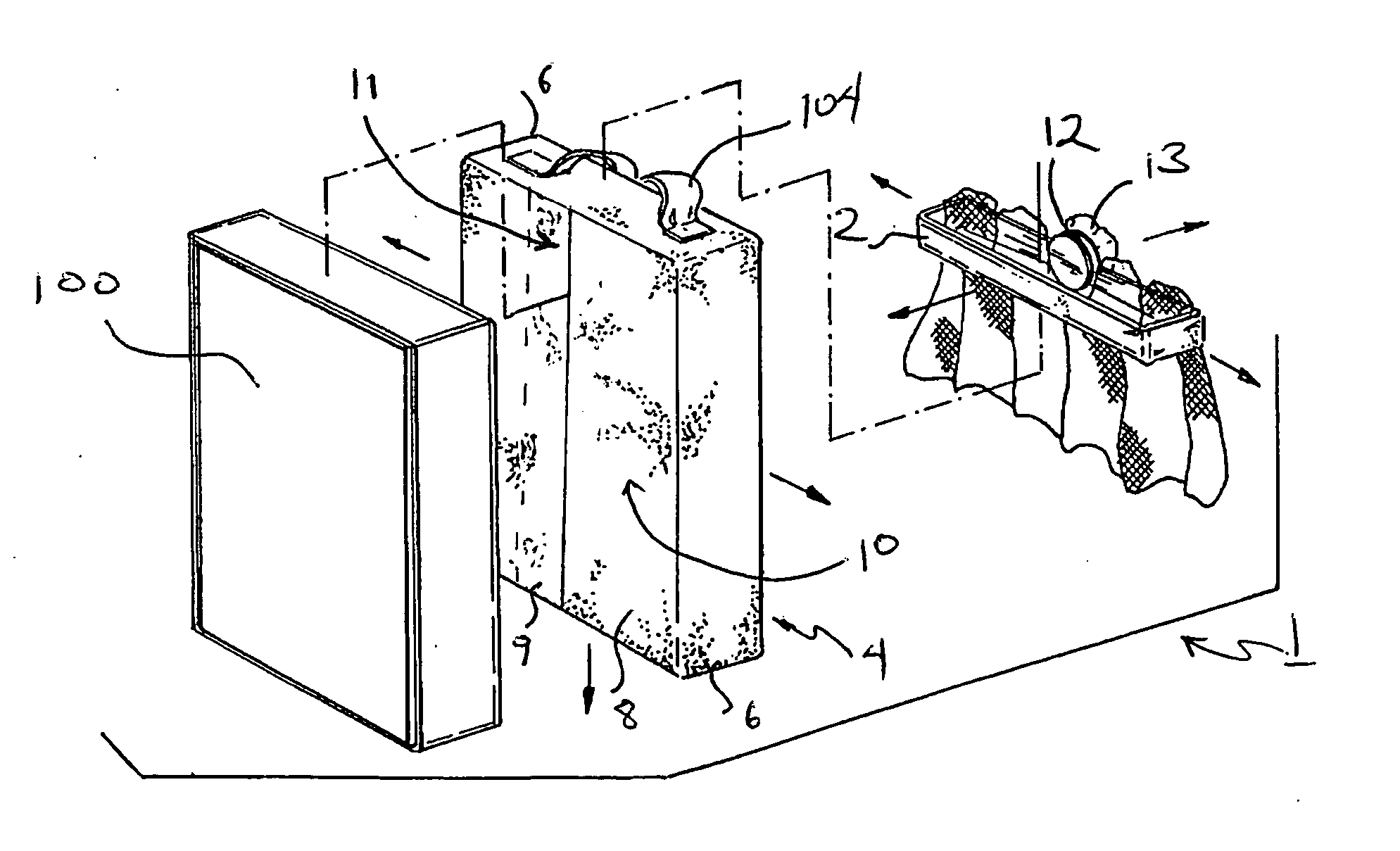

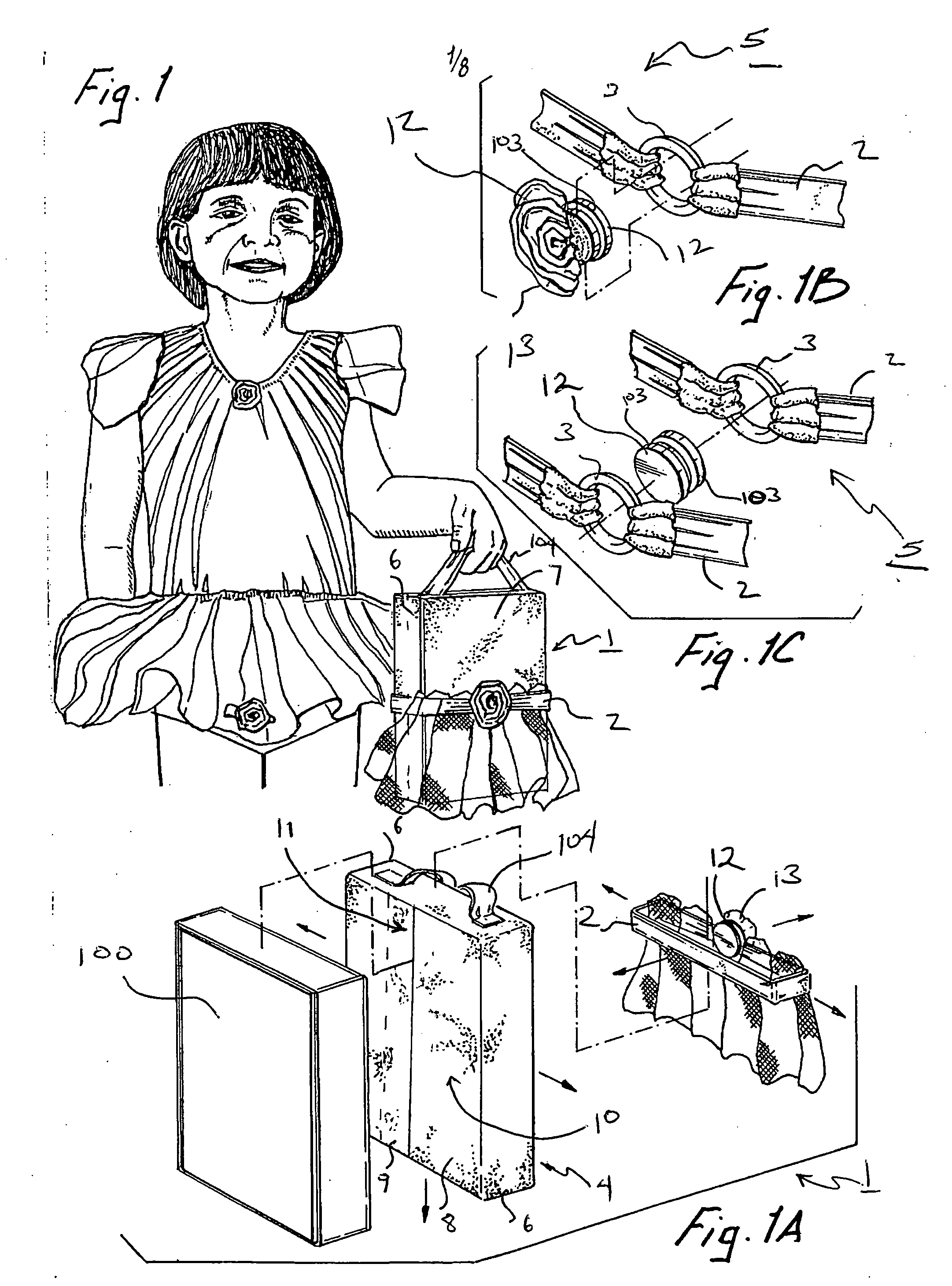

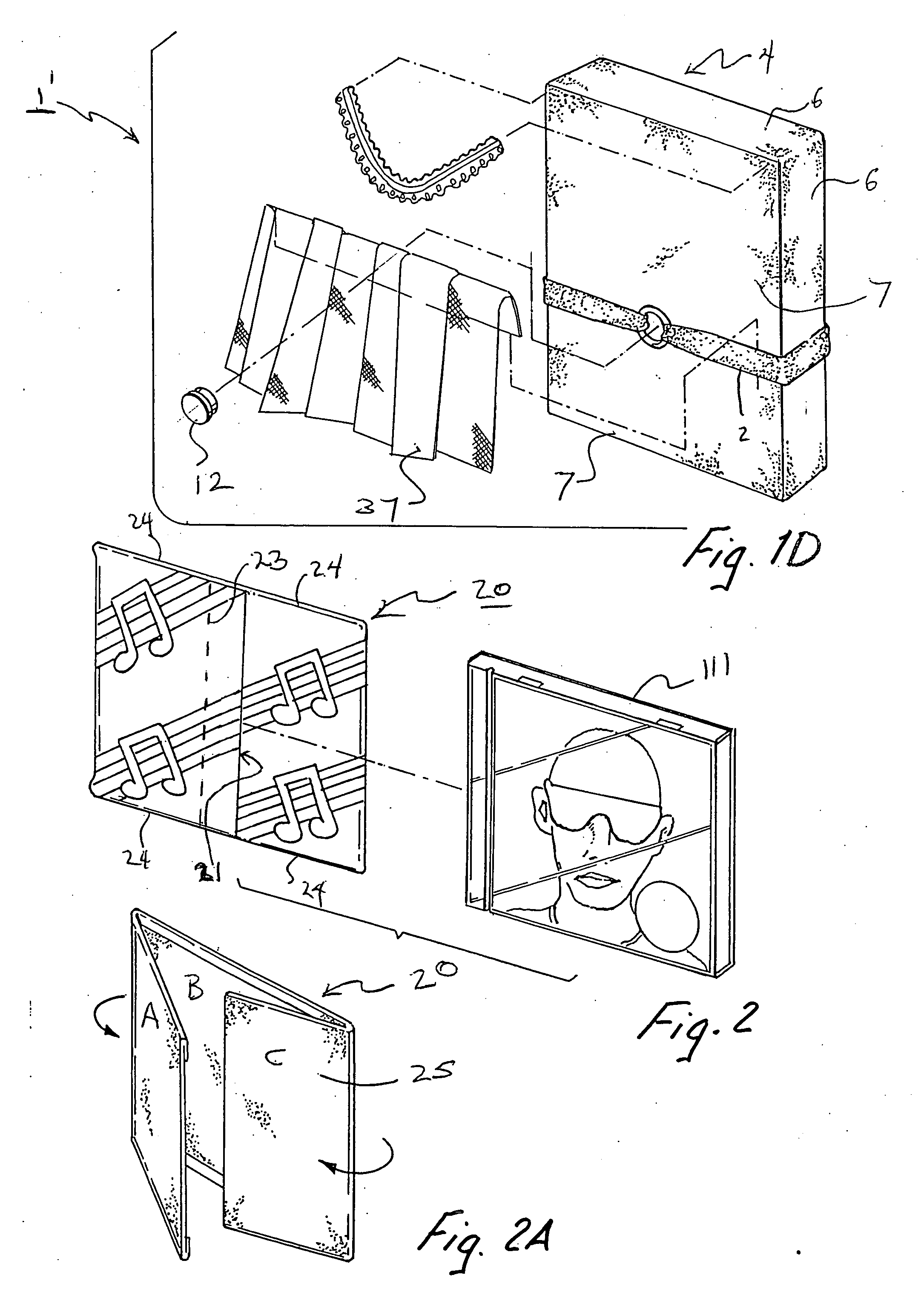

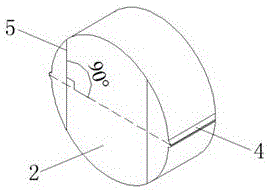

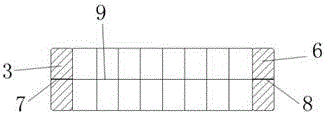

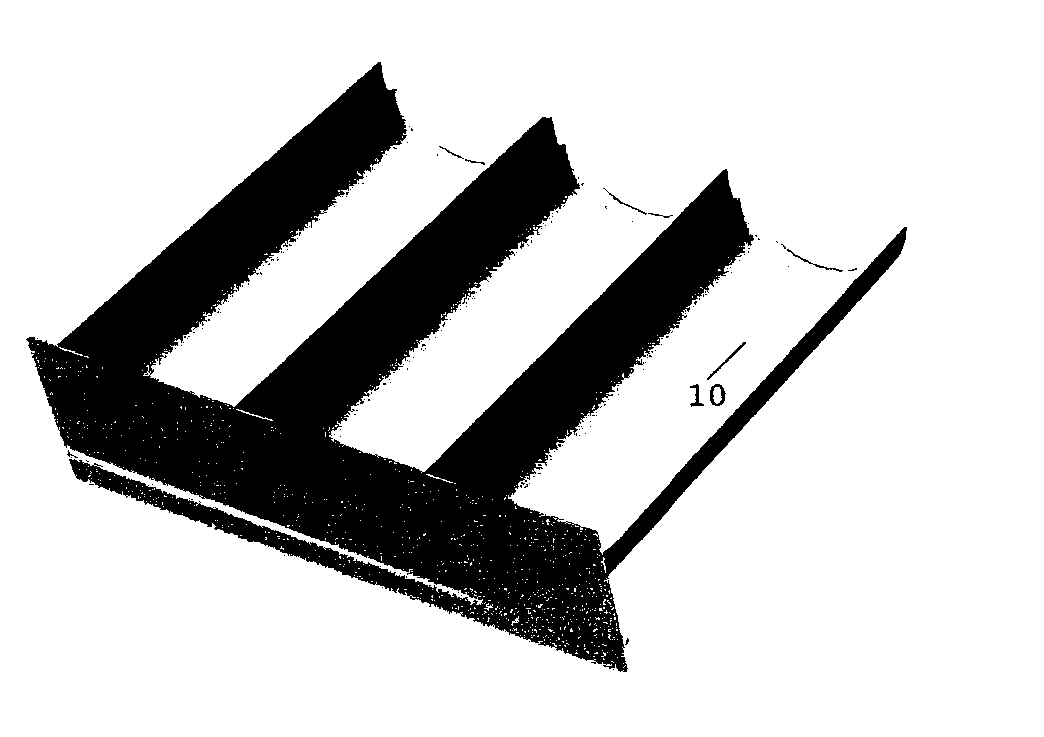

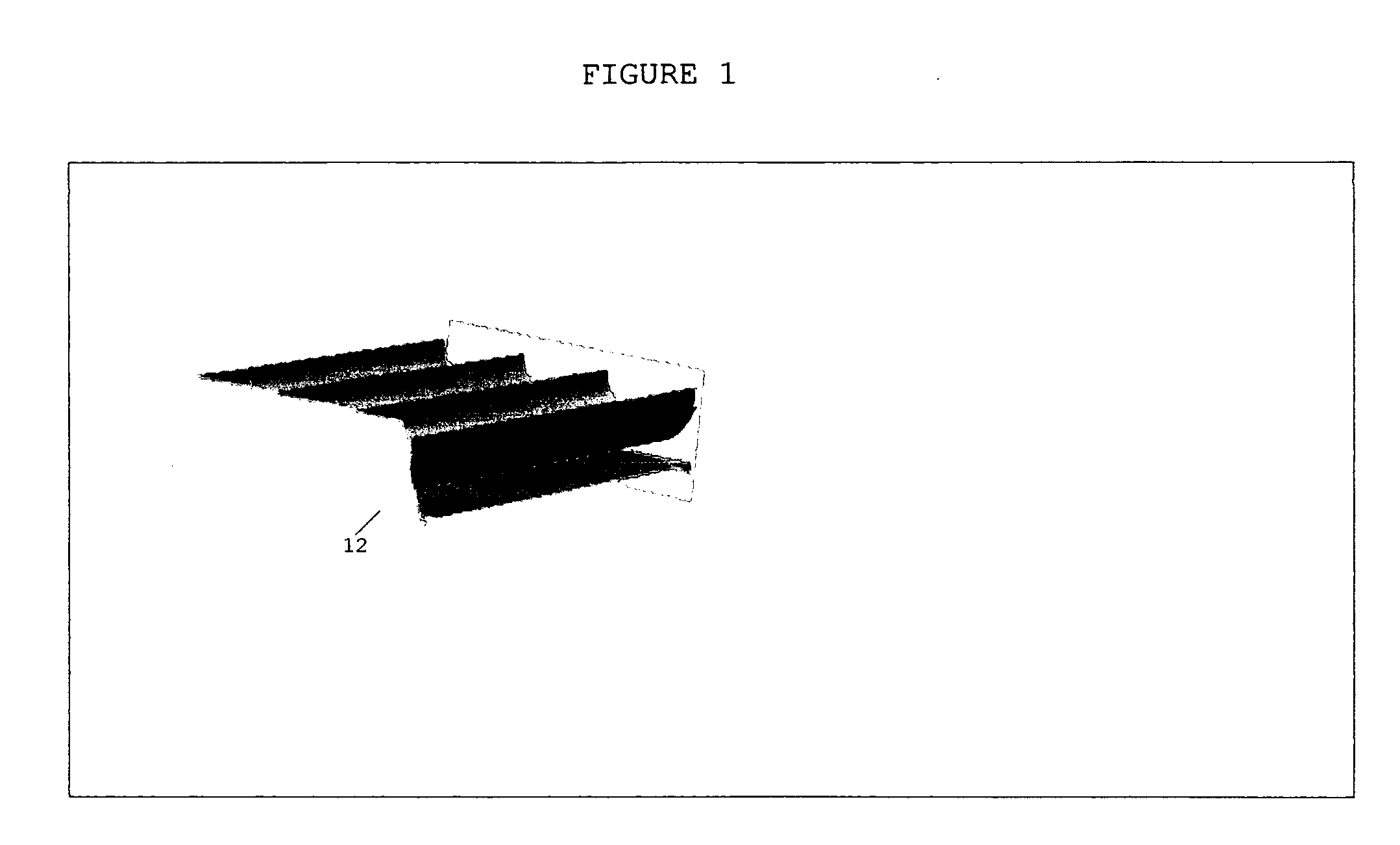

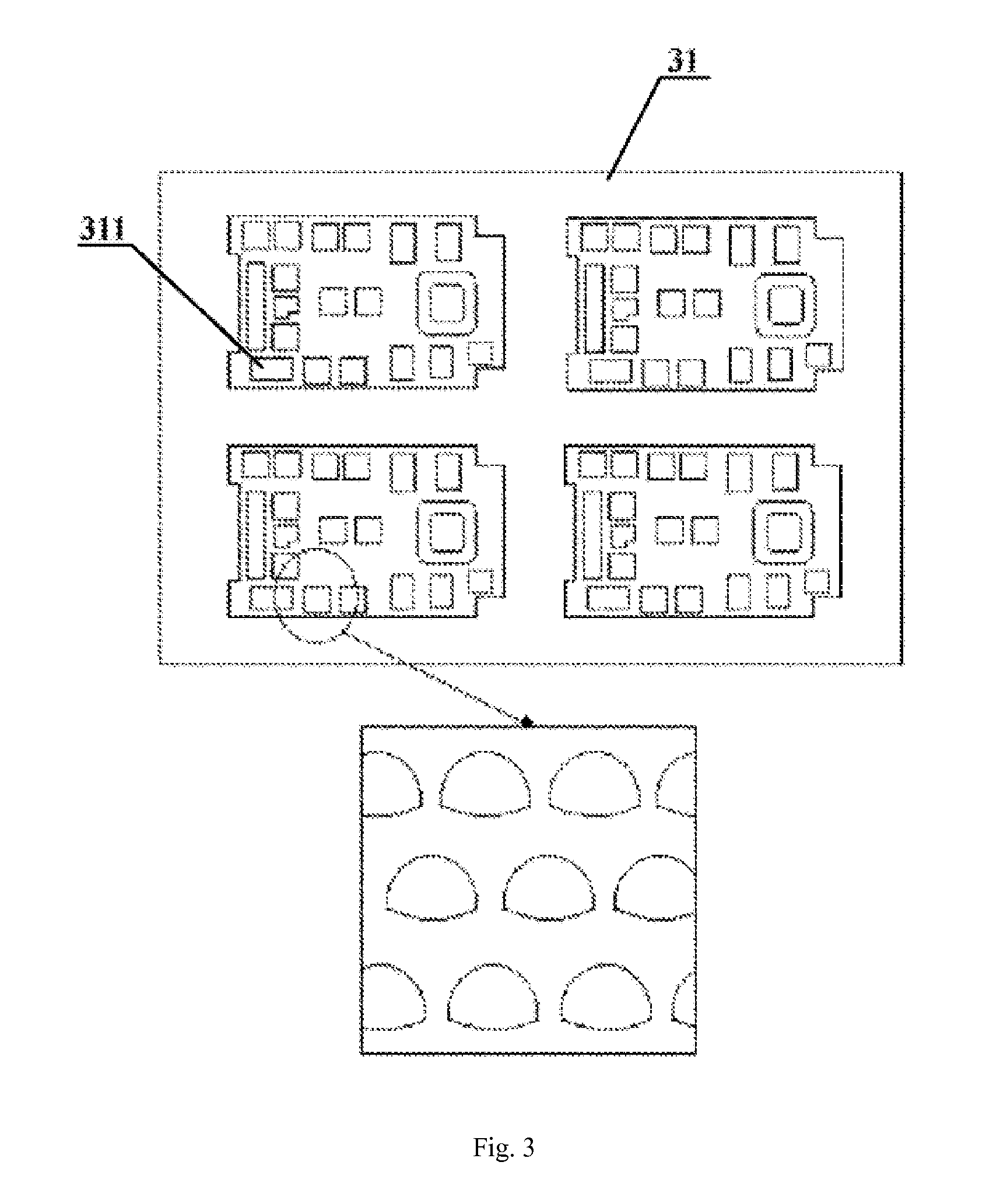

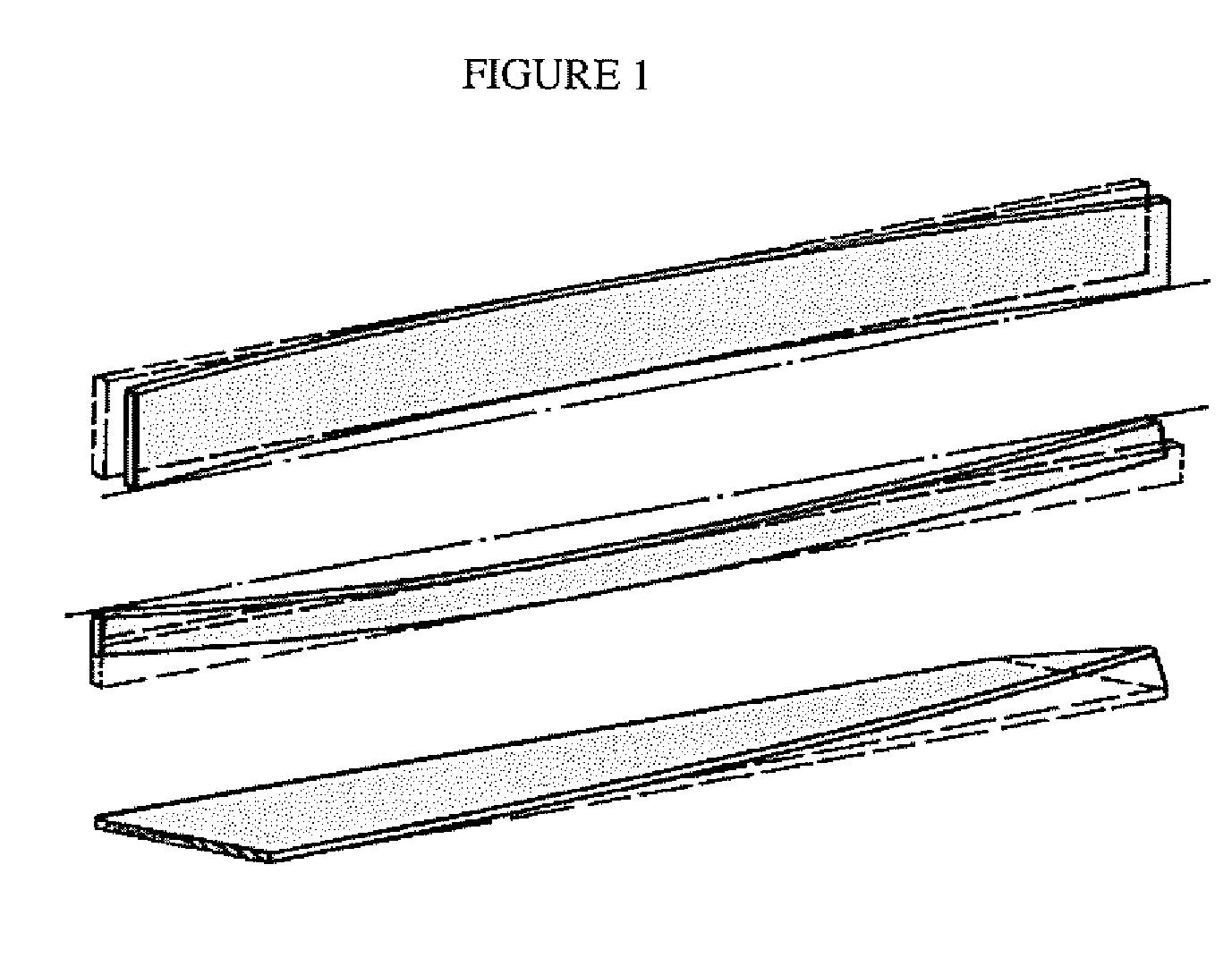

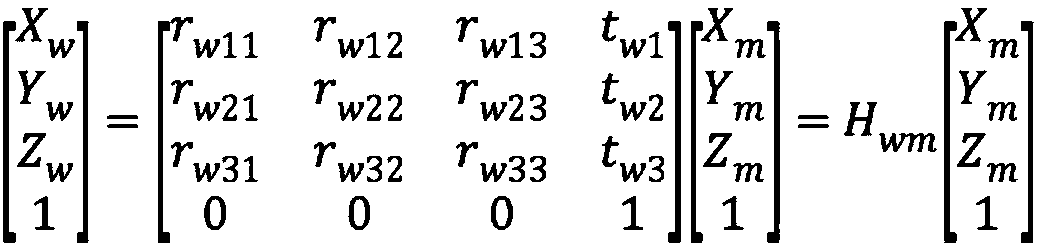

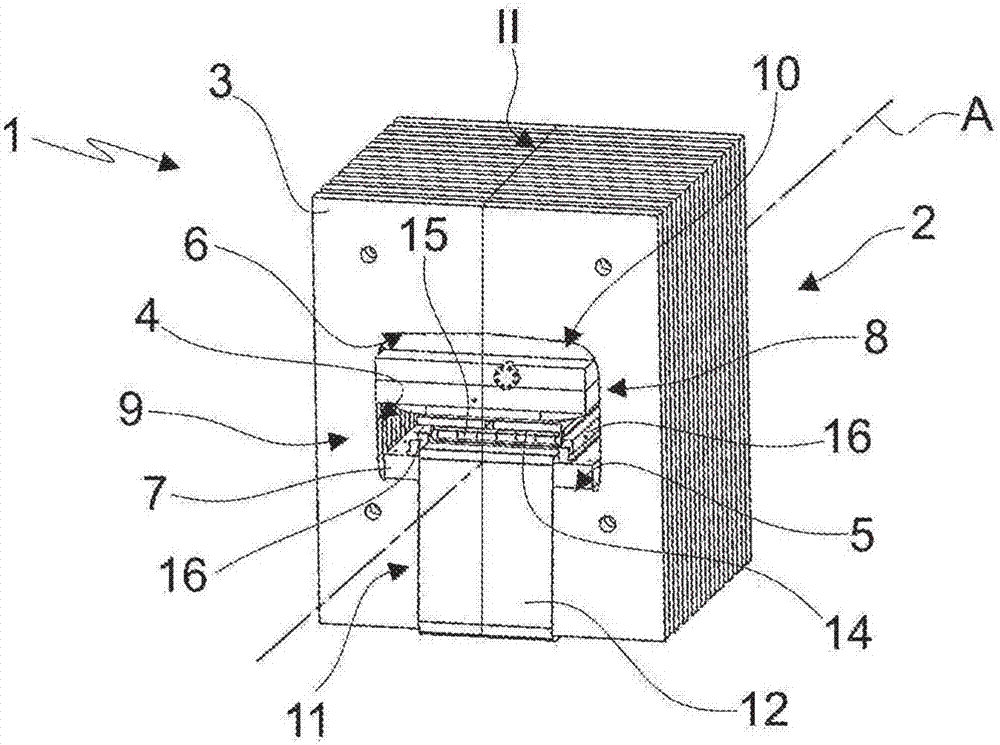

Press for large size products

A press for large-size ceramic products comprises a modular structure (2) defined by a plurality of annular plates (3), aligned in succession one after the other, and provided with a through seat (4) which has a lower portion (5) and an upper portion (6) opposite one another, a bed (7) supported by the annular plates (3) at the lower portion (5) and a head (8) connectable to the upper portion (6), wherein the bed (7) and the head (8) delimit a work chamber (9) for housing power elements (10) suitable for carrying out the operations of pressing a material to be pressed, and a conveyor belt (12) that passes through the through seat (4) along a longitudinal direction (C) of the modular structure (2), wherein the power elements (10) comprise at least one upper punch (14), first lateral holding elements (15) and second lateral holding elements (16) for the powder material to be pressed, movable with respect to one another and suitable for delimiting during use a work chamber where such powder material is pressed.

Owner:SITI B&T GRP

A kind of fpc manufacturing method of silk screen and dispensing to make covering layer

ActiveCN107801317BNo change in structureDo not change the materialOther printing apparatusPrinting after-treatmentScreen printingElectric-vehicle battery

The invention discloses an FPC manufacturing method with a covering layer manufactured through silk-screen printing and glue dispensing. The method comprises the steps of S1, silk-screen printing including, covering uncovered areas through a silk-screen board to expose areas to be printed, ensuring that every edge of board patterns to be printed shrinks inwards 0.75-1.25 mm compared with designedpatterns to be printed, printing ink onto the areas to be printed of a copper foil base material through a silk-screen printing machine to form silk-screen printed patterns; S2, glue dispensing including dispensing glue onto glue dispensing areas of the copper foil base material through a glue dispenser to fill up missed parts between the silk-screen printed patterns and the designed patterns, andensuring that every edge of the glue dispensing areas expands 1.5 mm compared with the designed patterns; S3, baking including heating glue-dispensed FPCs at 160-180 DEG C for 10 min. The FPC manufacturing method with the covering layer manufactured through silk-screen printing and glue dispensing can directly reduce production processes of products, especially large-dimension products such as signal collecting FPCs of energy storage and electric vehicle battery packs, and meanwhile, can reduce dependency on large-top customized pressing machine tools and save costs of machine tool purchase,labor and time.

Owner:奕东电子科技股份有限公司 +1

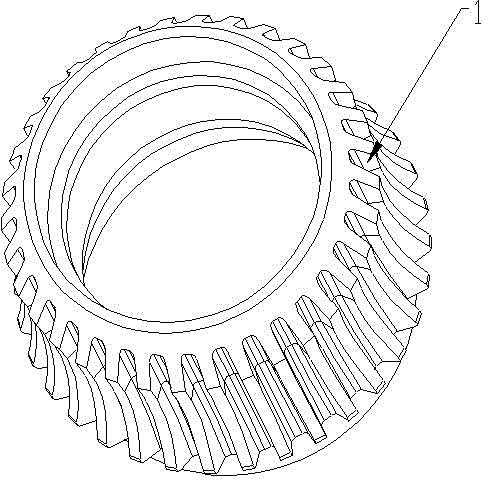

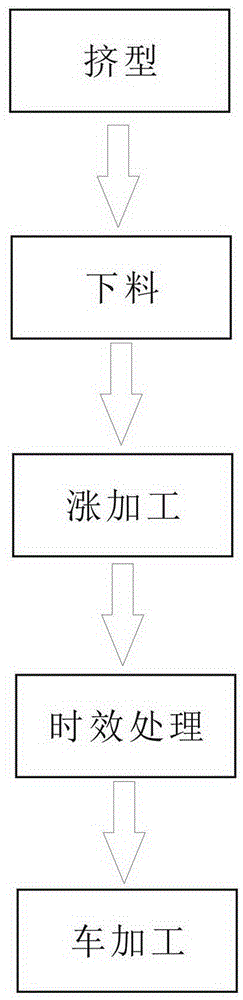

Manufacturing method for radiators

The invention belongs to the technical field of radiators in lamp illumination, in particular to a manufacturing method for the radiators. The manufacturing method is characterized by mainly including five steps of mold extrusion, blanking, expansion processing, aging treatment and lathing. A forging mode in the prior art is replaced by an expansion processing mode, and workpiece dimension products are expanded to be in the shape required by products, so that manufacturing cost is greatly reduced, and efficiency is improved.

Owner:中山市三丰精密铝制品有限公司

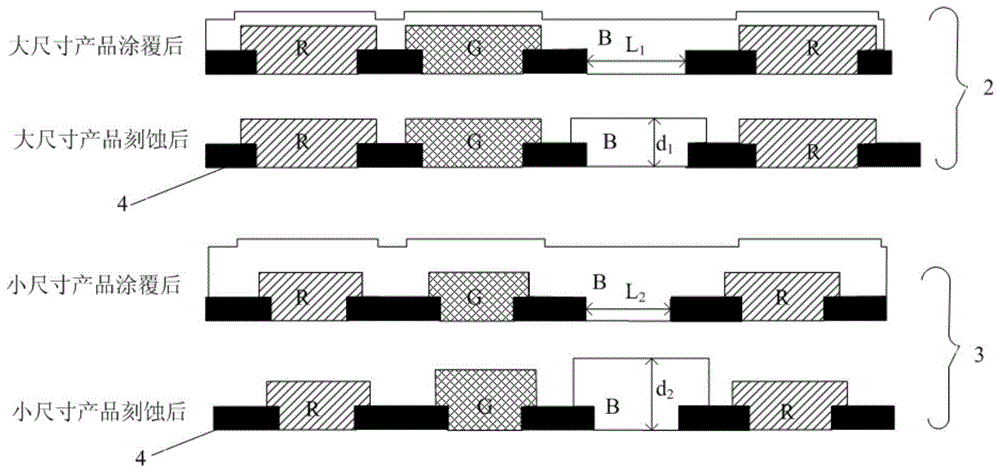

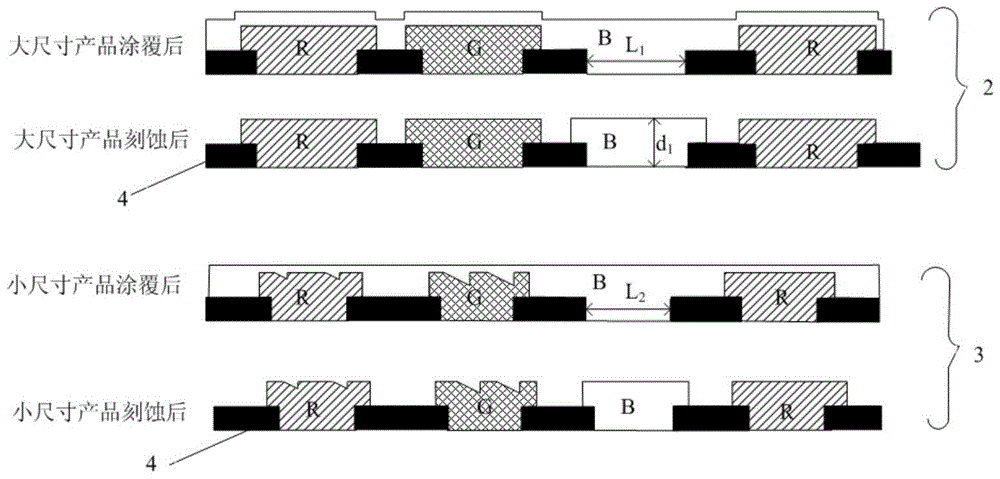

A kind of color filter and its preparation method and display motherboard

InactiveCN105137516BReduce accumulationUniform film thicknessOptical filtersProduction lineColor gel

The invention provides a color filter, a manufacturing method thereof and a display mother board, which belongs to the technical field of display. In the color filter, on the surface, far away from a substrate, of a color filter film with a different color in a small-size pixel opening area is provided with at least one groove, film layer accumulation caused by surface tension is reduced, effects that a product can finally get a consistent film layer thickness when the display mother board size is different, and the problem of poor display caused as the final actual pixel thickness of a product with a small size is over large can be effectively solved. The color filter of the invention can be applied to various display panels, and particularly display panels with different sizes cut by the display motherboard in a production line.

Owner:BOE TECH GRP CO LTD +1

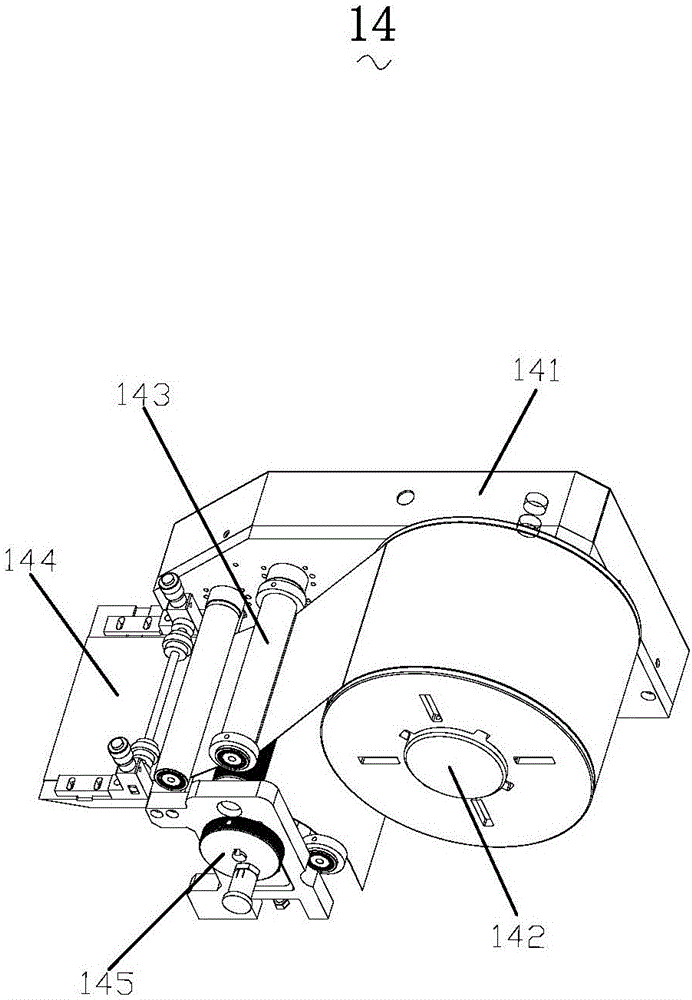

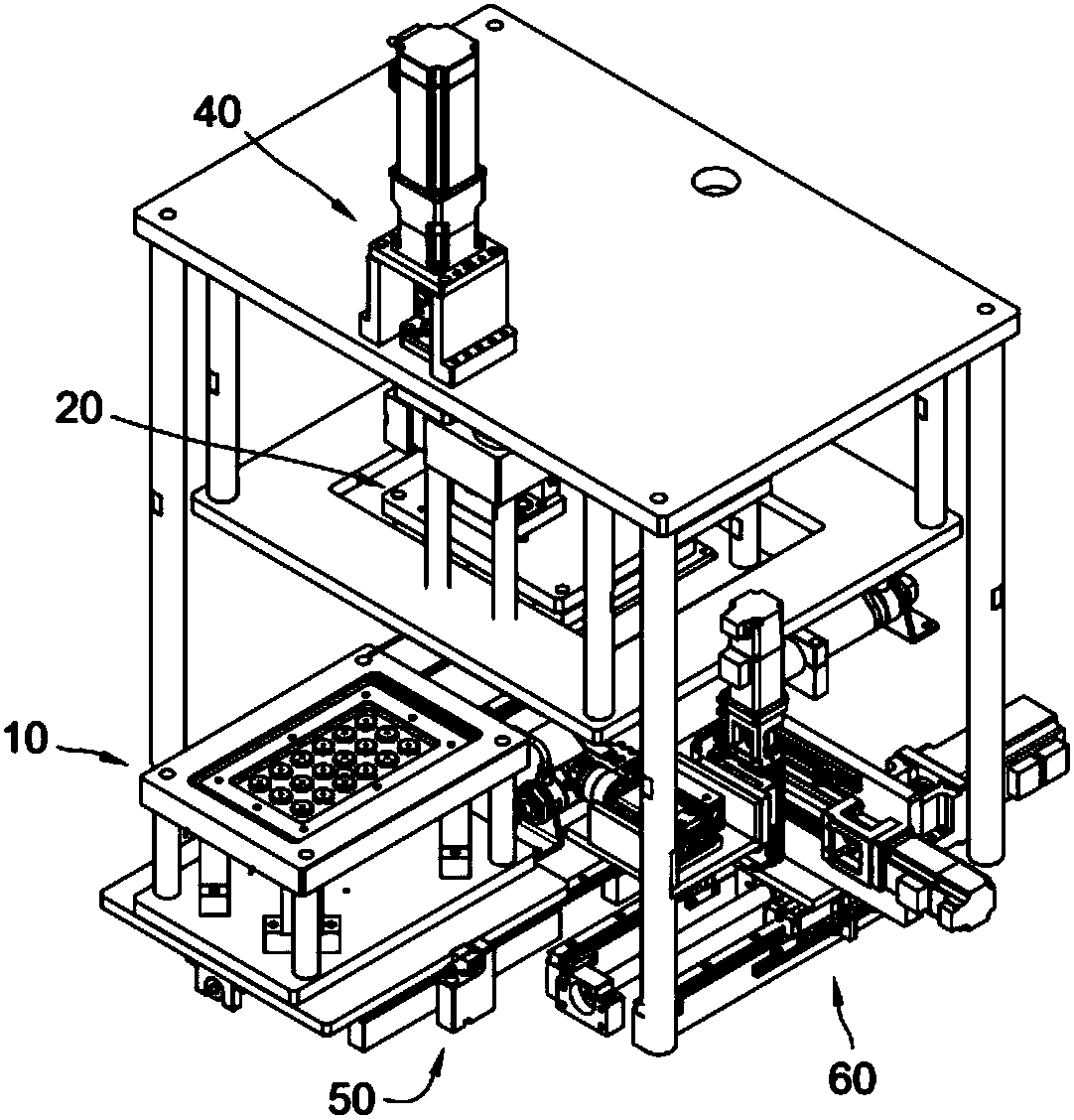

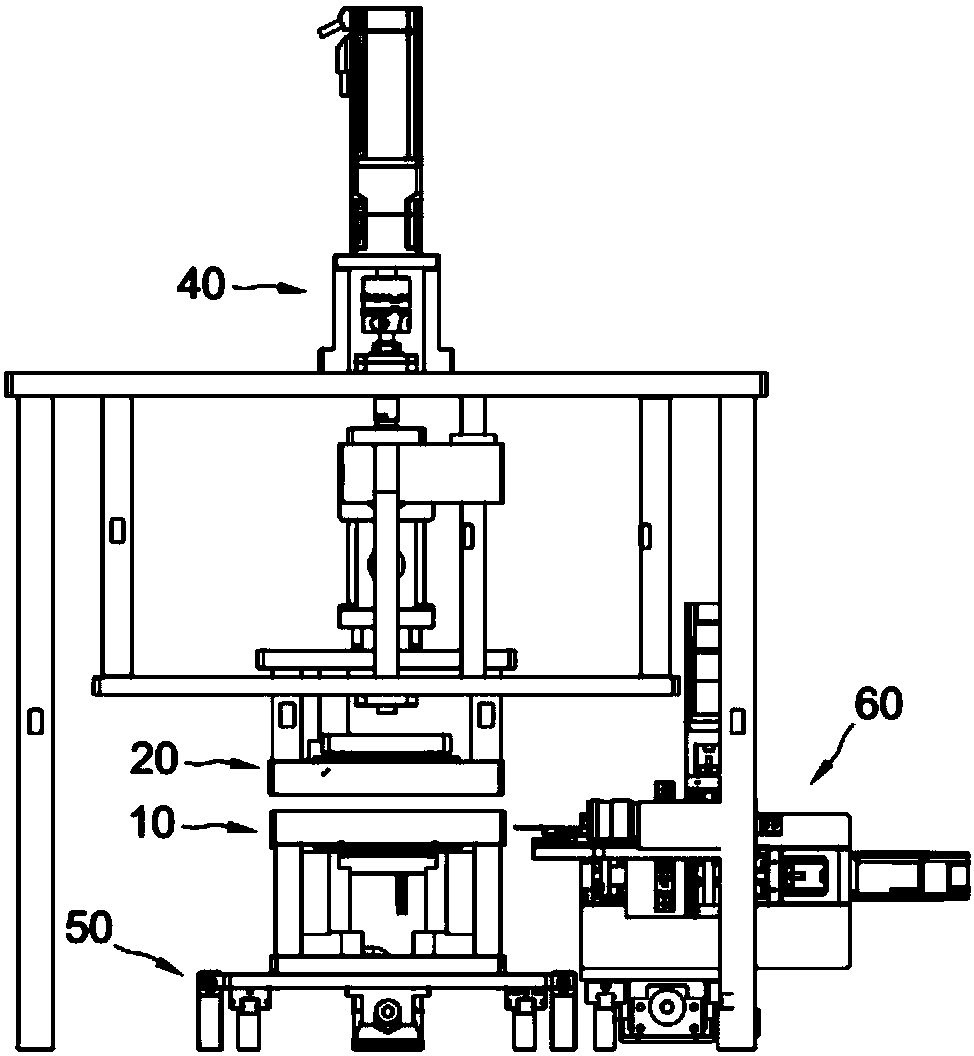

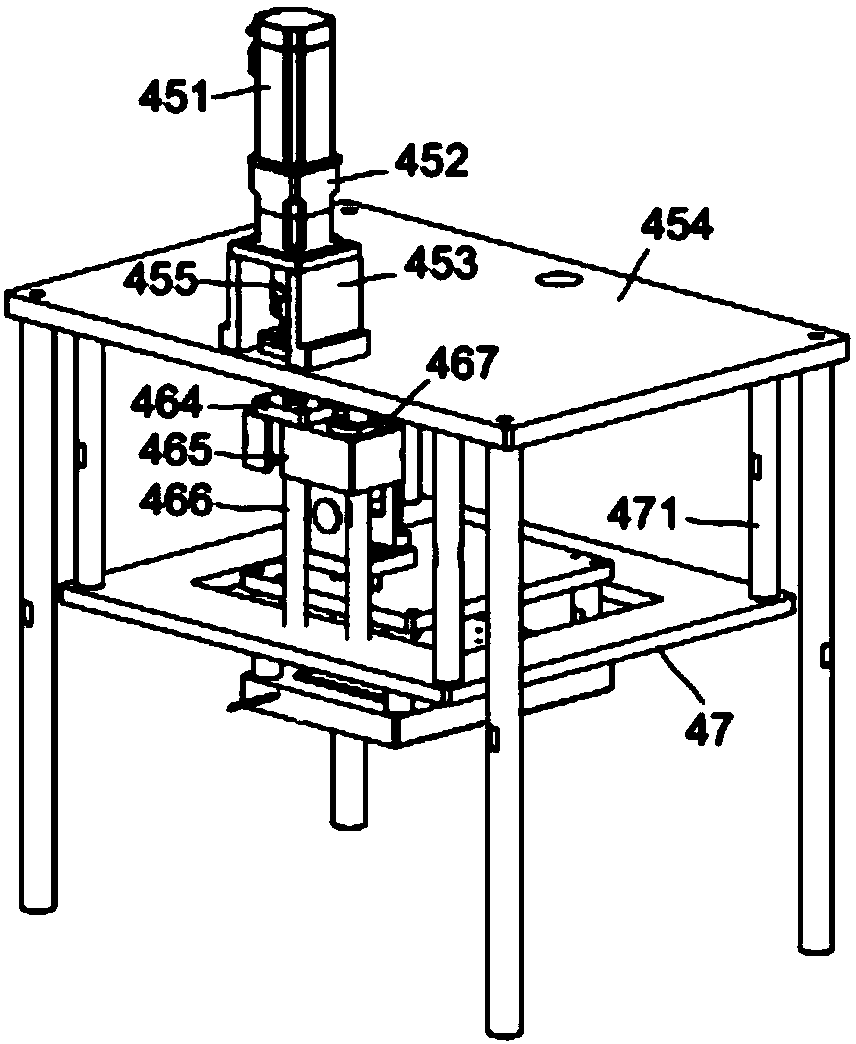

A hot-melt removal mechanism

ActiveCN106002209BImprove general performanceConvenient detection and adjustment of tension and pressureMetal working apparatusPull forceCoupling

Owner:BOZHON PRECISION IND TECH CO LTD

ccd glue machine

ActiveCN106122203BImprove quality and efficiencyIncrease productivityMaterial gluingAdhesiveIndustrial engineering

The invention provides a CCD adhesive attachment machine which comprises a product conveying belt. A product locating platform is arranged on the product conveying belt. A CCD alignment platform and a plurality of adhesive piece feeding mechanisms are arranged on one side of the product locating platform. A four-axis linkage mechanical arm freely moving above the product conveying belt, the product locating platform, the CCD alignment platform and the multiple adhesive piece feeding mechanisms is arranged on the other side of the product locating platform. The product locating platform comprises two fixed check blocks and two movable check blocks. Each fixed check block and the corresponding movable check block are arranged in a relatively parallel manner. According to the CCD adhesive attachment machine, attachment operation of single-sided adhesives and double-sided adhesives of products of different sizes can be achieved only through one set of equipment, and attachment operation of single-sided adhesives and double-sided adhesives in different shapes and different sizes and at different positions can be achieved on the same product; product quality and production efficiency are greatly improved; normal operation of a machine table is operated only with one person; and production personnel are saved for enterprises well.

Owner:SHENZHEN WEIHONGKE TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com