A kind of color filter and its preparation method and display motherboard

A color filter and color filter film technology, applied in the direction of the filter, can solve the problems of large pixel thickness and poor display, and achieve the effect of reducing the accumulation of film layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

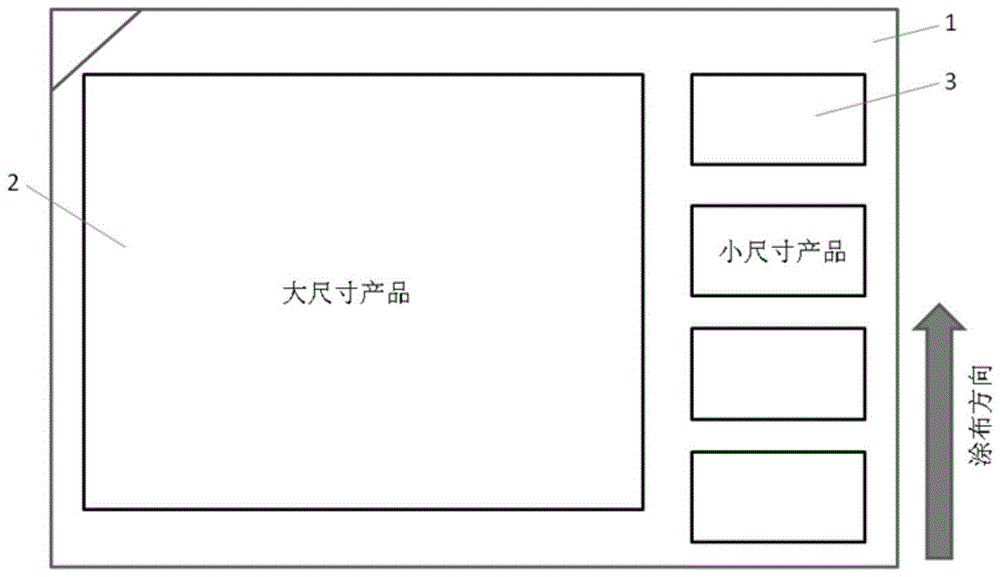

[0028] This embodiment provides a color filter, including a substrate, a black matrix arranged on the substrate, the area on the substrate not covered by the black matrix forms a sub-pixel opening area, and the sub-pixel opening area is provided with A color filter film, the color filter includes at least two sizes of sub-pixel opening areas, wherein the color filter film of a partial color in the small-size pixel opening area is provided with at least one groove on the surface away from the substrate.

[0029] In the color filter of this embodiment, at least one groove is provided on the surface of the color filter film of part of the color in the small-sized pixel opening area away from the substrate, so as to reduce the accumulation of film layers caused by surface tension and realize the display motherboard. Large and small products of different sizes have the same final film thickness of each layer, thus effectively solving the problem that the final actual pixel thickness...

Embodiment 2

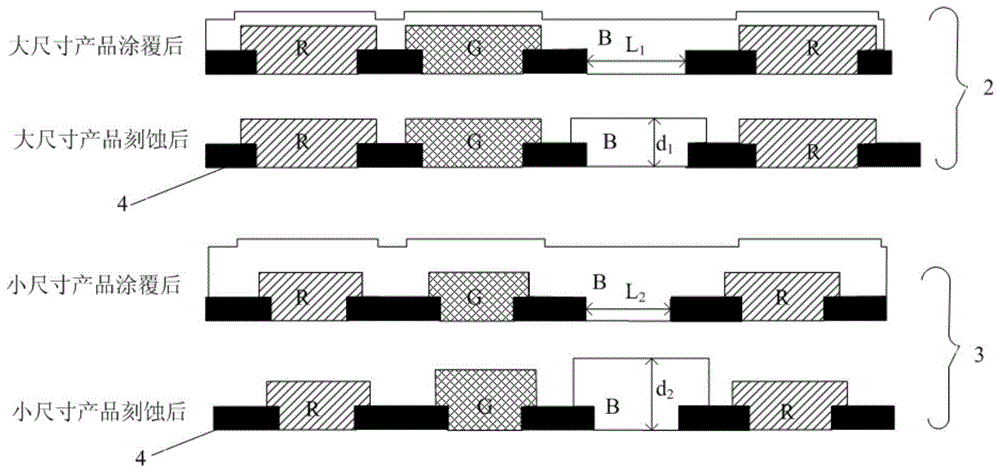

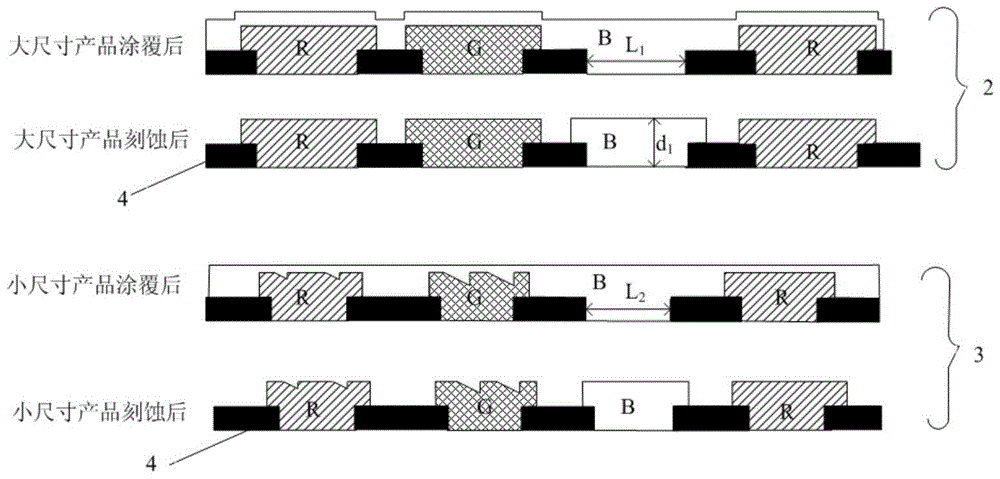

[0031] This embodiment provides a color filter, such as image 3 , Figure 4 As shown, it includes a substrate, a black matrix 4 arranged on the substrate, the area not covered by the black matrix 4 on the substrate forms a sub-pixel opening area, and the sub-pixel opening area is provided with a color filter film, so The color filter includes at least two sizes of sub-pixel opening areas, wherein, at least one groove is provided on the surface of the color filter film of a partial color in the small-size pixel opening area away from the substrate.

[0032] That is to say, at least one groove is provided on the surface of the color filter film of part of the color in the small-sized pixel opening area away from the substrate, so as to reduce the accumulation of film layers caused by surface tension and realize the display of products with different sizes of large and small motherboards. Finally, the film thickness of each layer is consistent, thereby effectively solving the p...

Embodiment 6

[0051] This embodiment provides a method for preparing the color filter of Embodiment 2, the method includes the step of forming grooves on the surface of the color filter film of a partial color in the small-sized pixel opening area away from the substrate.

[0052] Preferably, the color filter film is formed by a photolithography process.

[0053] That is to say, the color filter film is coated on the whole layer first, and then the pattern is completed using a mask plate. Take the formation of the third color filter film B as an example for illustration (at this time, the first color filter film R and the second color filter film G have been completed), as image 3 As shown, after R and G are completed, the entire layer of B is coated, and then the B pixels other than the opening area of the B pixel are etched away to form a B pixel.

[0054] Preferably, the method specifically includes the following steps:

[0055] forming a first color filter film;

[0056] forming a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com