Online measuring method used during optical fiber alignment base array manufacturing with silicon substrate technology

An optical fiber alignment and pedestal technology, which is applied in the photoengraving process, optics, measuring device and other directions of the pattern surface, can solve the problems of measurement value error and the accuracy cannot meet the requirements of mass production, etc., and achieve high-precision online line width monitoring. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

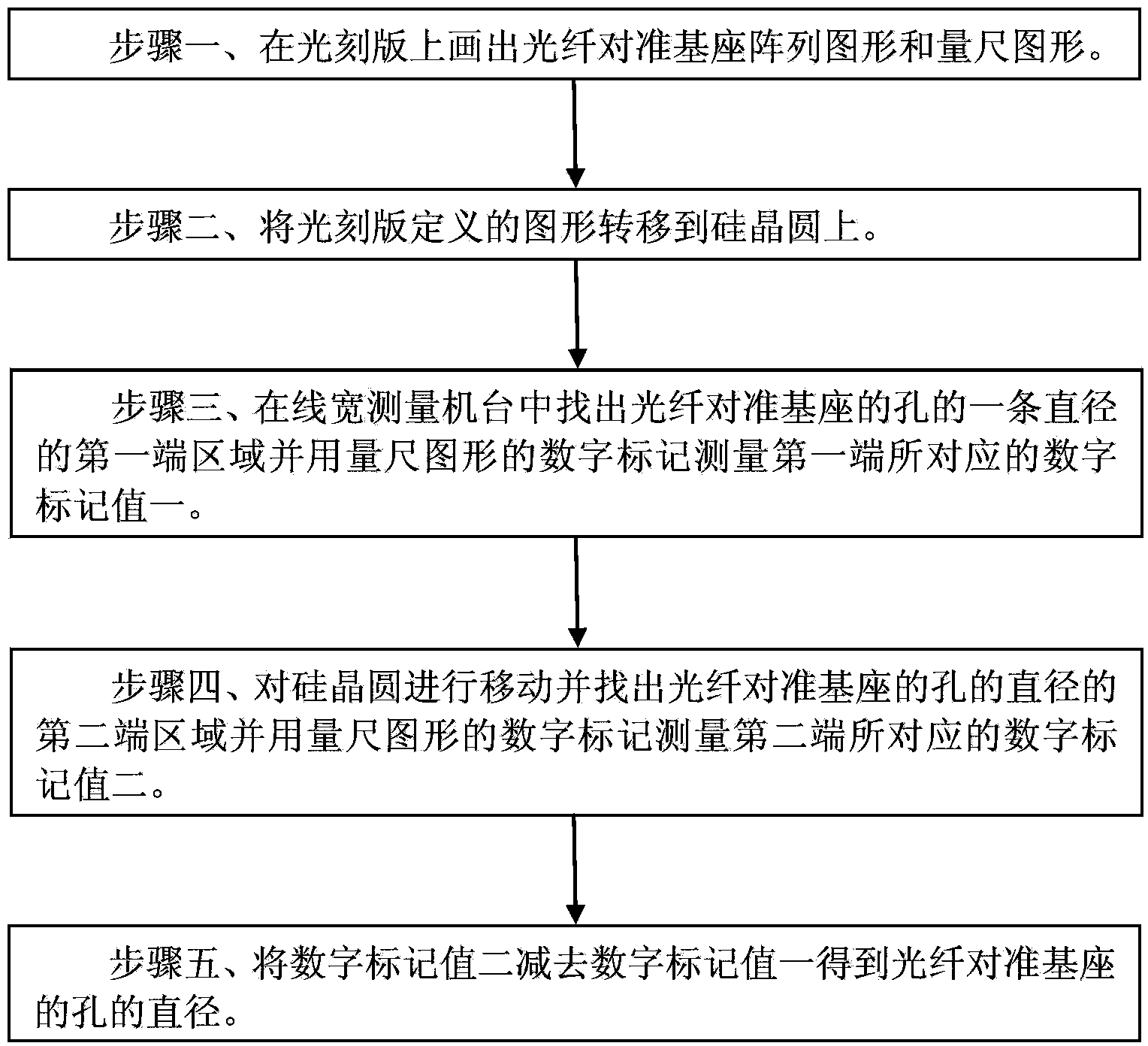

[0021] like figure 1 As shown, it is a flow chart of the method of the embodiment of the present invention; the online measurement method for making an optical fiber alignment base array in the silicon-based process of the embodiment of the present invention includes the following steps:

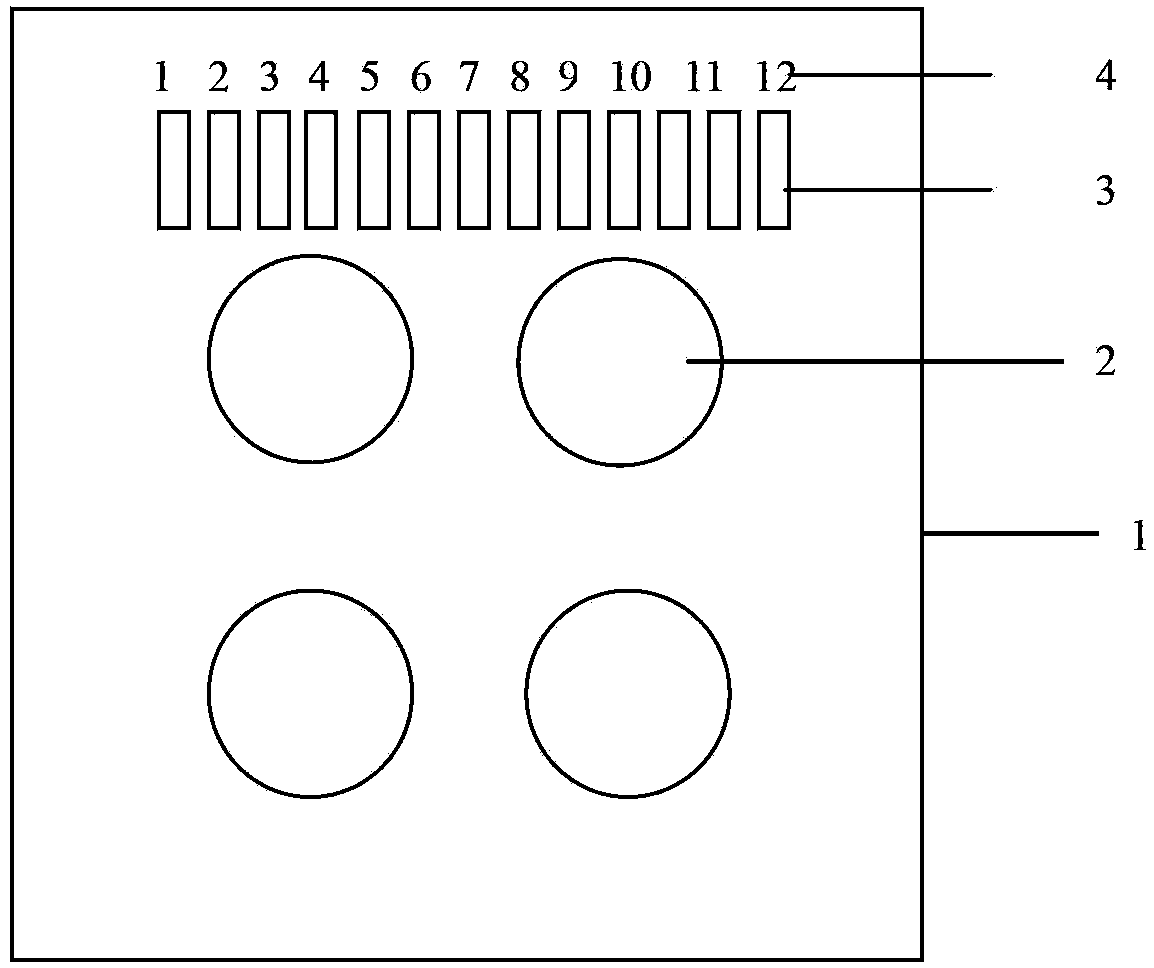

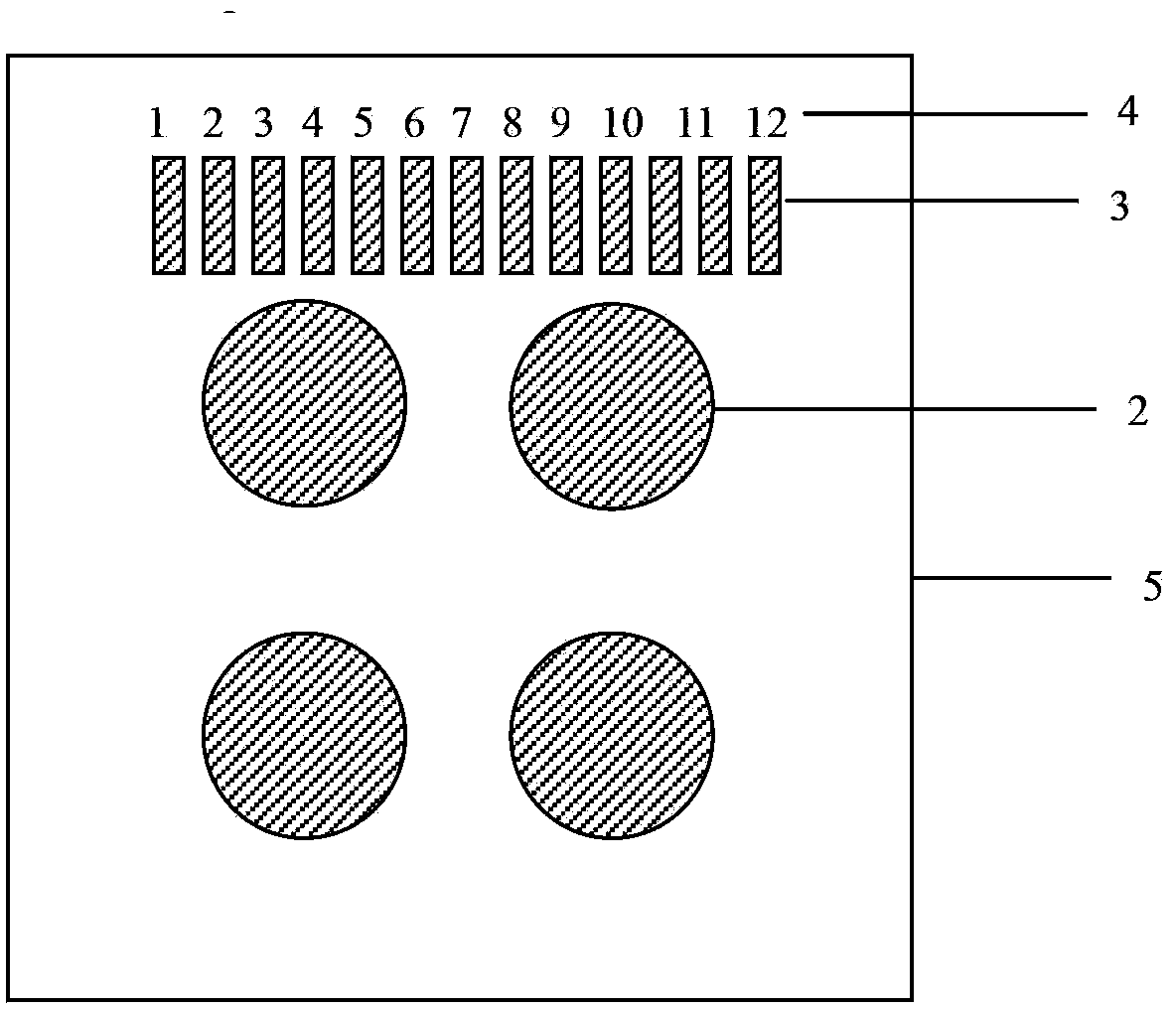

[0022] Step one, as figure 2 As shown, the photoresist plate 1 is made, and the optical fiber alignment base array pattern and the scale figure 3 are drawn on the photoresist plate 1, and the fiber alignment base array pattern defines the holes of the fiber alignment base 2 arrays of size and permutation.

[0023] The scale figure 3 is composed of a series of bar figures with fixed line width and spacing, the line width of the bar figures is 0.1 micron to 1 micron, and the distance between two adjacent bar figures is 0.1 Micron~1 micron, the sum of the line size and spacing of each of the bar graphics of the scale figure 3 is fixed, and the sum of the line size and spacing of each of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com