Processing method for preparing shape memory product

A processing method and deformation processing technology are applied in the processing field of preparing shape memory products, which can solve the problems of waste, high cost of forming and processing, and complicated procedures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

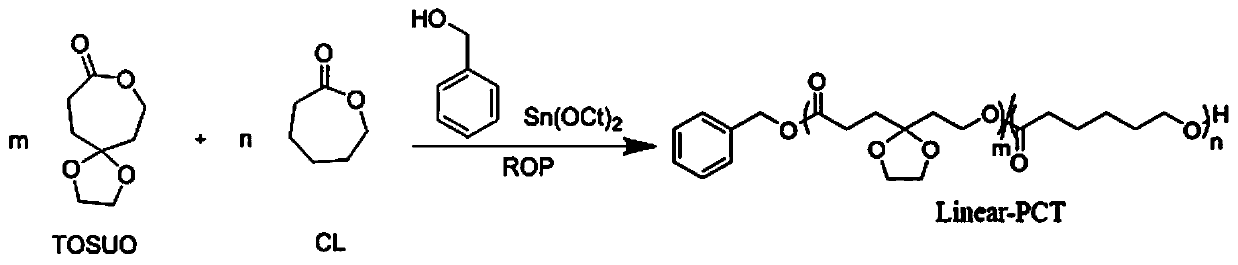

[0055] According to the method in the literature "design and synthesis of elastic polycaprolactone based on pendant cyclic ether modification and its application in soft tissue engineering", linear PCT with a mass ratio of CL to TOSUO of 85:15 was prepared, and the synthesis reaction formula is shown in image 3 .

[0056] The synthesis method is mainly as follows: After purifying and drying the comonomer and drying the ampoule for polymerization, weighing the required content of TOSUO and CL into the dried ampoule, adding Required content of Sn(Oct) 2 (One-thousandth of the molar weight of the cyclic monomer) toluene solution and benzyl alcohol, stirring at room temperature and vacuuming, using the azeotropic effect of toluene to remove traces of water in the reaction system, until no bubbles are generated for at least 30 minutes, melt and seal the tube . The tube-locked product was stirred and reacted in an oil bath at 130°C for 24 hours. After the reaction was completed, ...

Embodiment 2

[0061] The thermally induced shape memory linear PCT with crystallinity in Example 1 is used, and its spline thickness is 1.0mm and width is 3.8mm, so that it can be applied to the situation where the installation space is large and the use space is small.

[0062] Stretching 5 mm long splines to 6.5 mm with DMA at 20 °C brought them into a bulky temporary shape. Keep the initial product of stretched splines while cooling down to 0°C, and fix the initial product with a large volume of temporary shape for 4 minutes, and then pass it through a larger installation space. After the initial product is installed in the desired position, it is heated to 40°C to allow it to retract freely, and finally a 5.6mm spline product is obtained.

Embodiment 3

[0064] The thermally induced shape memory linear PCT with crystallinity in Example 1 is used, and its spline thickness is 1.0mm and width is 3.8mm, so that it can be applied to the situation where the installation space is large and the use space is small.

[0065] Stretch 5 mm long splines to 6.5 mm with DMA at 25 °C to bring them into a bulky temporary shape. Keep the initial product of stretched splines while cooling down to 0°C, and fix the initial product with a large volume of temporary shape for 4 minutes, and then pass it through a larger installation space. After the initial product is installed at the desired position, it is heated to 40°C to allow it to retract freely, and finally a 5.5mm spline product is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com