Manufacturing method for large-dimension high-precision samarium-cobalt magnet

A technology of samarium cobalt magnet and manufacturing method, which is applied in the direction of inductor/transformer/magnet manufacturing, manufacturing tools, magnetic objects, etc., can solve problems such as difficulties, and achieve the effect of overcoming the difficulty of processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

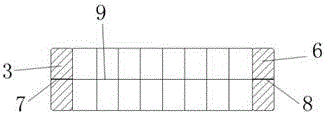

[0044] Manufacture a samarium cobalt product with an outer diameter of 42±0.01mm, a thickness of 122±0.2mm, a perpendicularity of 0.01mm, a parallelism of 0.01mm, a cylindricity of 0.01mm, radial orientation, and a performance grade of Sm2Co17-34H. The steps are:

[0045] s1) Trimming the six faces of the sintered square blank, and smoothing the six faces of the square blank.

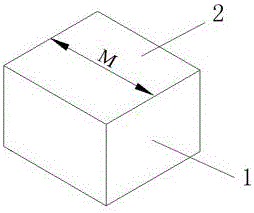

[0046]s2) Mark the two orientation planes of the square blank as A plane and B plane 1 respectively, select two opposite planes from the four planes perpendicular to the orientation plane and mark these two planes as C plane 2 and D respectively noodle.

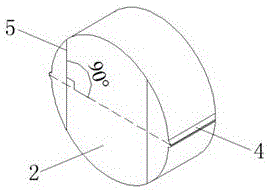

[0047] s3) Roughly grind C surface 2 and D surface, grind off the scale on these two surfaces, and smooth these two surfaces; draw 2~3 lines perpendicular to the orientation on C surface 2 and D surface The first identification line 5 of the surface.

[0048] s4) Carry out vertical grinding on the A surface and the B surface 1, grind off the scale o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com