Combined nesting die-cutting process

A die-cutting and nesting technology, applied in metal processing and other directions, can solve the problem of wasting a lot of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

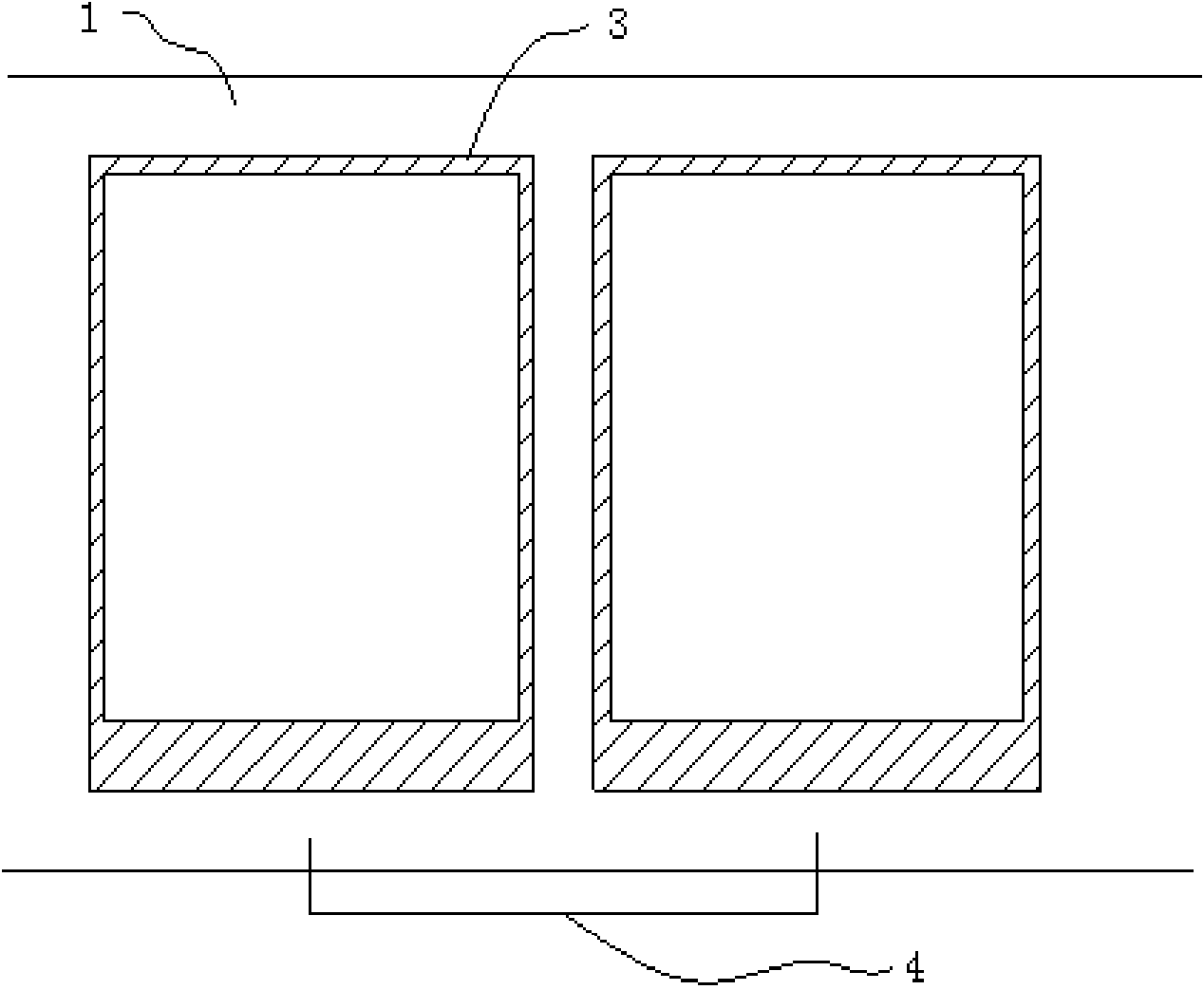

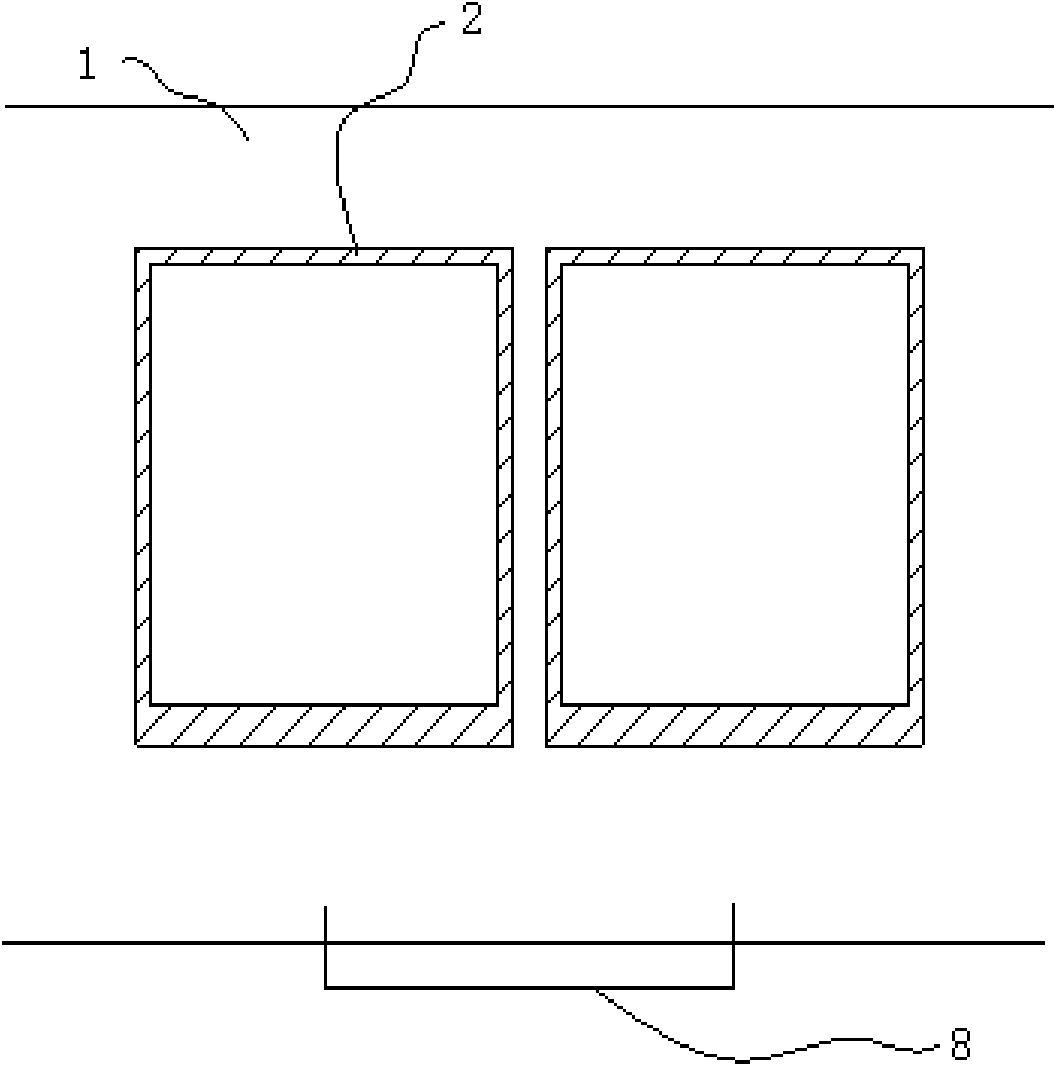

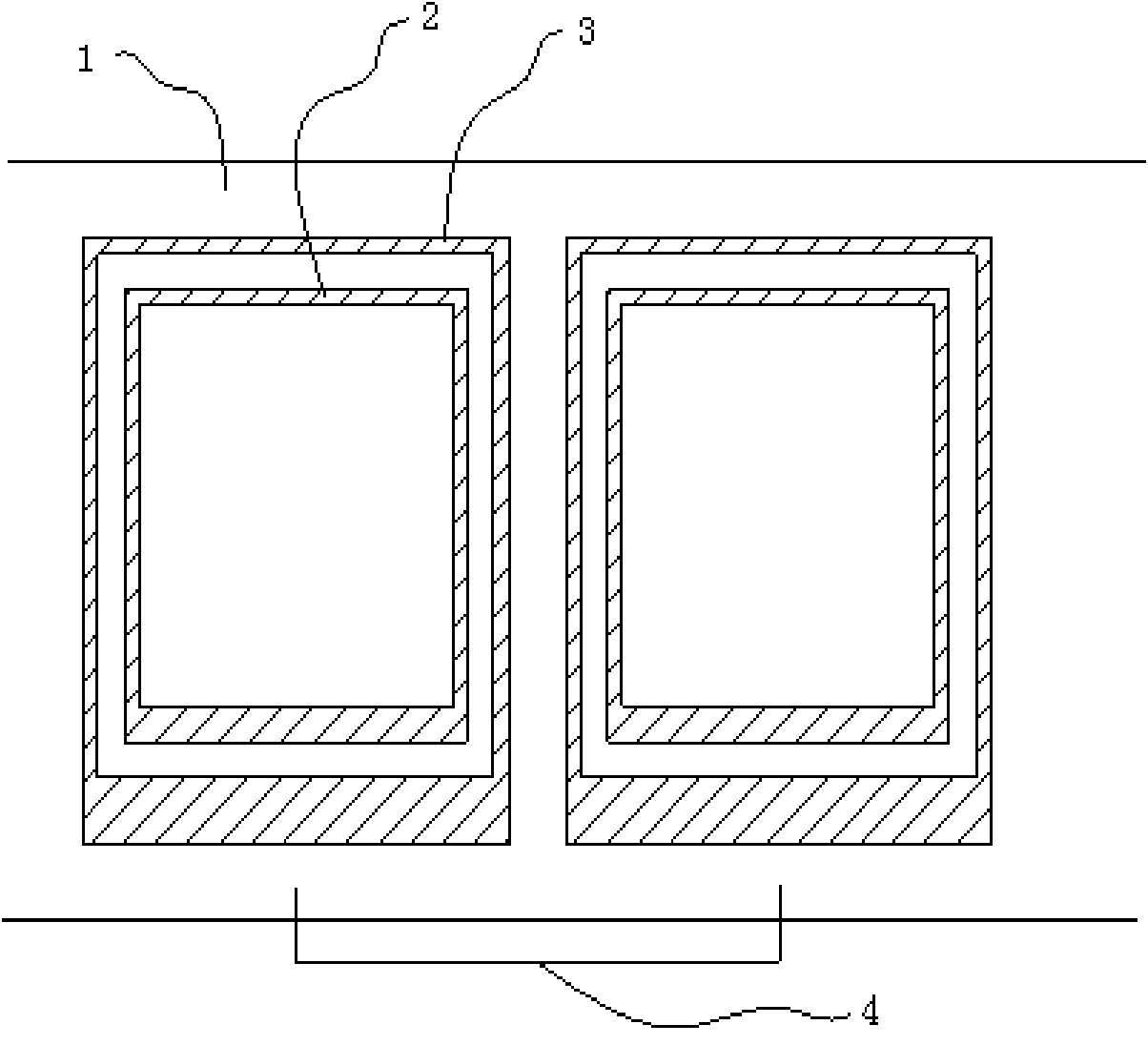

[0065] Embodiment 1: Die-cutting method from inside to outside: Two products of the same material and different sizes are chosen as examples for illustration. The product is mainly double-sided glued foam 6 . First double-sided adhesive tape 5 is applied on both sides of the foam, the original backing paper 11 of the double-sided adhesive tape 5 is replaced, the upper layer of adhesive is coated with the outer backing paper I1, and the lower layer of adhesive is coated with the outer backing paper II7. If the existing separate die-cutting process is used, the large-size products 3 are arranged in a manner of jump distance 4 (see attached Figure 1-I ), the small size products 2 are arranged according to the jump distance 8 (see attached Figure 1-II ), so that the inner and outer materials of the two products are wasted. Switch to a new die-cutting process: first design the combined arrangement of nested products (see attached drawing 1-111 attached drawing 1-VI), there is no ...

Embodiment 2

[0072] Embodiment 2: Die-cutting from outside to inside: at this moment, the first die 14 and the second die 17 are respectively the inner edge die and the outer edge die of large-sized products; the third die 18 and the fourth die Die 19 is respectively the outer edge cutting die and the inner edge cutting die of small size products. The process of making large-sized products remains the same, but the first row of waste 21 is the first main waste. After removing the backing paper I1 on the upper surface, the backing paper I1 is combined, and the front is die-cut to cut through the backing paper I1 and the main material. Cut through the backing paper II7, and separate the backing paper I1 and the backing paper II7; Figure 9 ), the vertical line that cuts through the main material in the figure indicates the position of the die-cutting; then compound the backing paper III on the upper surface and separate it, and the main material outside the outer edge of the small-sized prod...

Embodiment 3

[0073] Embodiment 3: If the large and small size products are to be produced in time, the discontinuous backing paper I1 on the upper surface of the first main waste discharge after the large-size product is made is replaced with a continuous backing paper I and stored as the next small Raw materials for dimension products. When using this raw material to produce small-size products, arrange and design first to ensure that the jump distance of the small-size products is the same as that of the original large-size products.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com