Manufacturing method for radiators

A manufacturing method and heat sink technology, applied in the field of heat sinks, can solve the problems of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but it is not intended to limit the present invention.

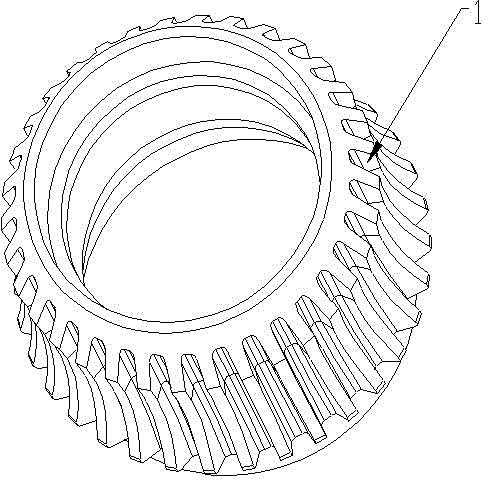

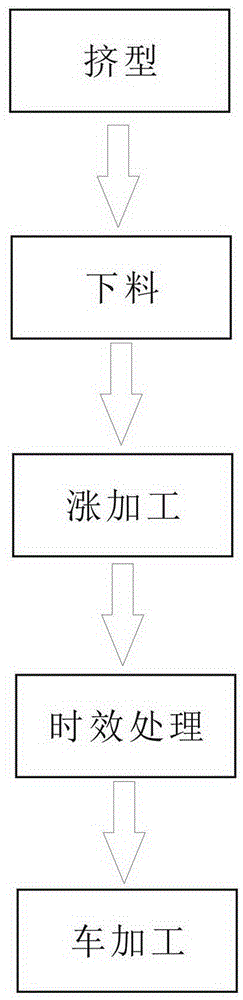

[0014] refer to figure 1 and figure 2 ,from figure 1 and figure 2 As can be seen from the figure, a method for manufacturing a heat sink according to an embodiment of the present invention mainly includes the following steps:

[0015] The first step, extrusion, heats the aluminum material to between 430°C and 470°C, then extrudes the aluminum material into a strip product using a mold and an extruder, and then manually straightens it;

[0016] The second step is blanking, using a sawing machine to cut the extruded aluminum strip product into the workpiece size according to the requirements, so as to prepare for the next process;

[0017] The third step is expansion processing. Use a punch to expand the workpiece size product out of the shape required by the product. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com