3D printing method and device for one-way large-dimension products

A technology of 3D printing and printing devices, which is applied in the direction of manufacturing auxiliary devices, processing drive devices, 3D object support structures, etc., can solve the problems of changing material structures, exceeding requirements, and limiting, etc., to achieve guaranteed performance and dimensional accuracy, and flexible temperature control , the effect of an effective solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

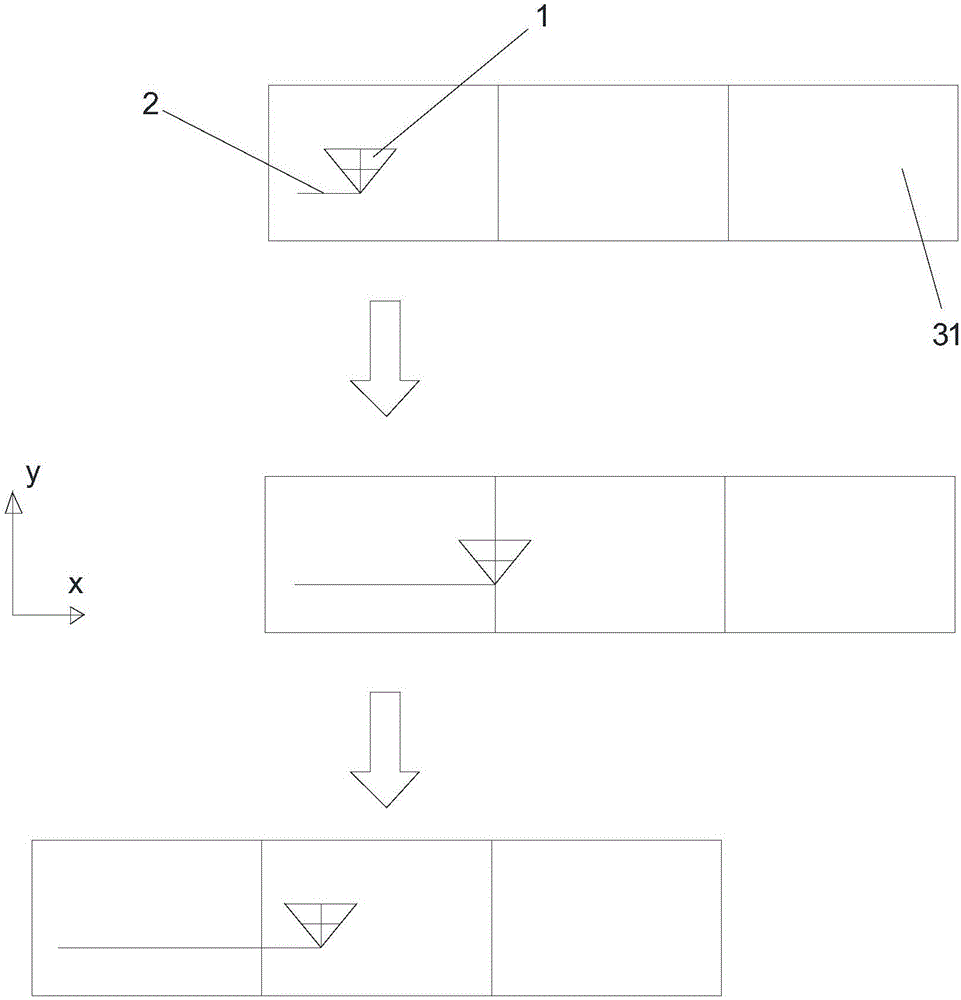

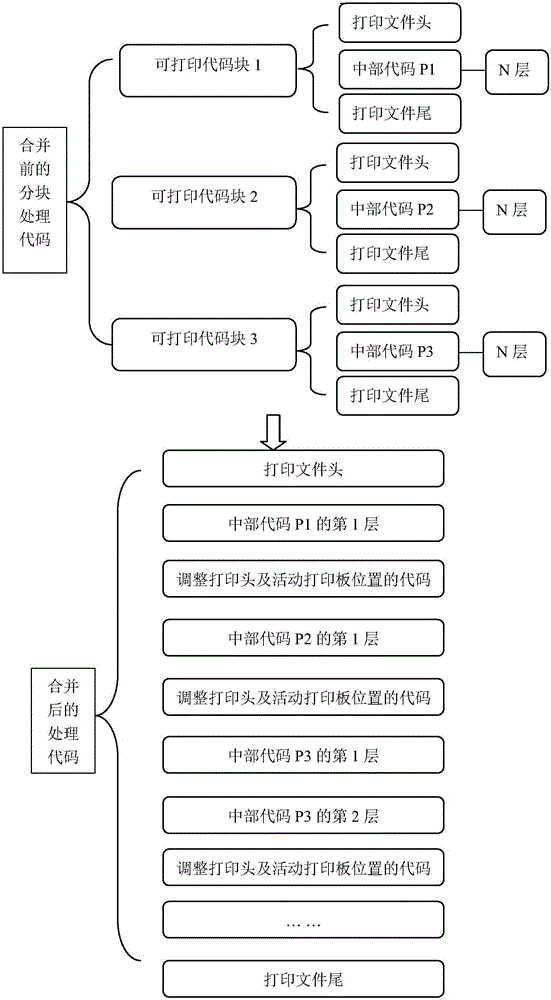

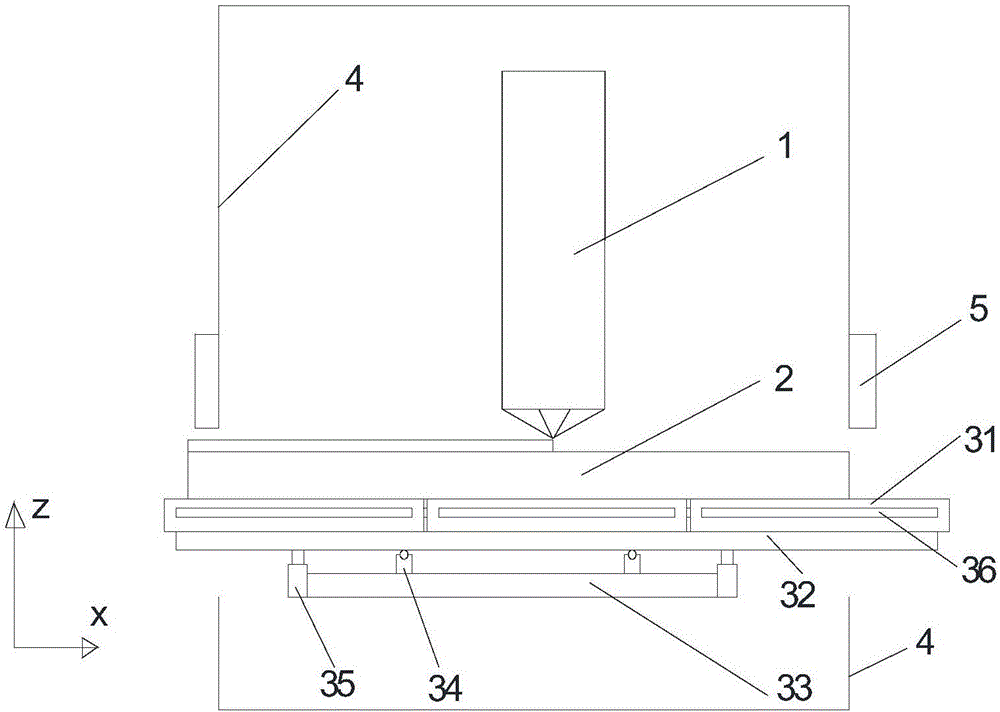

[0032] In order to be able to break through the size limit of the existing 3D printer in a certain direction, in this embodiment, the X direction is taken as an example, and the use of three movable printing boards is used as a representative, and the pretreatment method and printing method of the corresponding printed parts The device and printing process are described as follows:

[0033] 1) Pretreatment of printed parts

[0034] When it is necessary to print a unidirectional large-size part, in addition to the pre-processing method similar to the conventional printed part, the following two aspects need to be dealt with. First, assuming that the length of the active printing plate in the X direction is 500mm, the printed part When the X direction of the piece is 1001 ~ 1500mm, it is determined that the number of blocks required is 3 (1500 / 500 = 3), and there are plug-in parts at the end of the movable printing board, and there are temperature control components inside the m...

Embodiment 2

[0044] The printing process in Example 1 realizes block printing between each layer. In this way, the number of movements of the printing plate is only 2N times (N layers). In order to be closer to the printing path of the existing 3D printing, in the implementation On the basis of Example 1, this embodiment still takes the large-size product in the X direction as an example, and uses 3 movable printing plates as a representative, and the pre-processing method, printing device and printing process of the corresponding printed product For illustration. but,

[0045] 1) Pretreatment of printed parts

[0046] When it is necessary to print a unidirectional large-size part, in addition to the pre-processing method similar to the conventional printed part, the following two aspects need to be dealt with. First, assuming that the length of the active printing plate in the X direction is 500mm, the printed part When the X direction of the piece is 1001-1500mm, the number of blocks r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com