Backlight module material reliability test fixture

A technology for testing fixtures and backlight modules. It is used in optical instrument testing, machine/structural component testing, optics, etc. It can solve problems such as inability to simulate materials, affect test results, and affect development time, so as to shorten the development cycle. , the effect of reducing costs and reducing development risks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

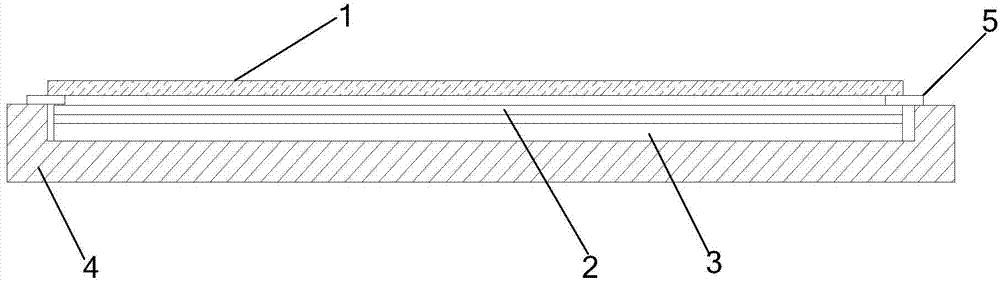

[0029] Such as figure 1 As shown, the backlight module is mainly composed of a light source (not shown in the figure), a light guide plate 3, an optical film material 2, and structural components. Structural components such as backlight module frame 4, light-shielding double-sided adhesive tape 5, etc. The optical film material 2 includes a diffusion sheet, a prism sheet, and the like.

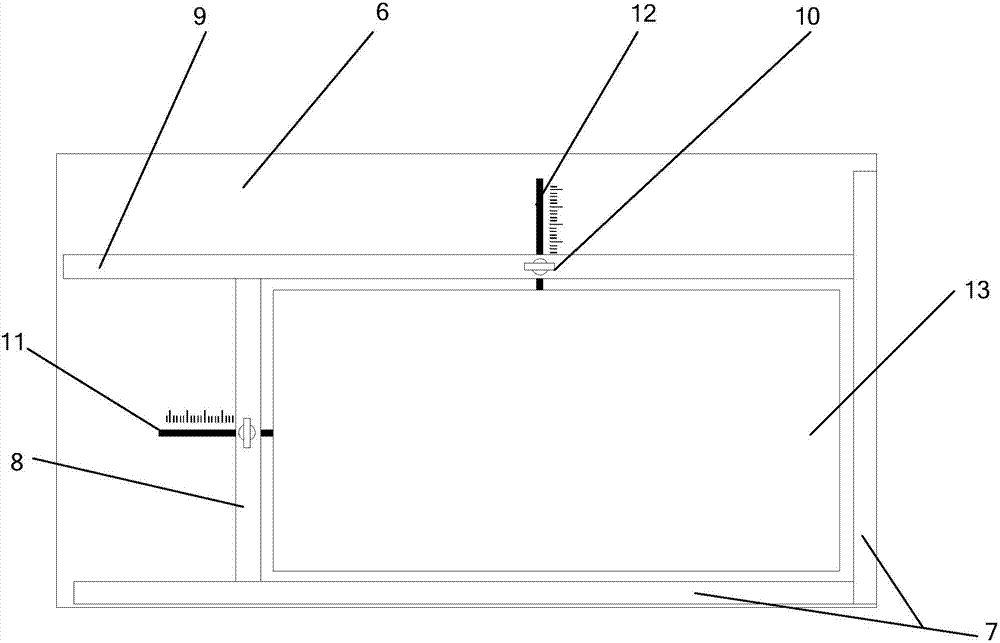

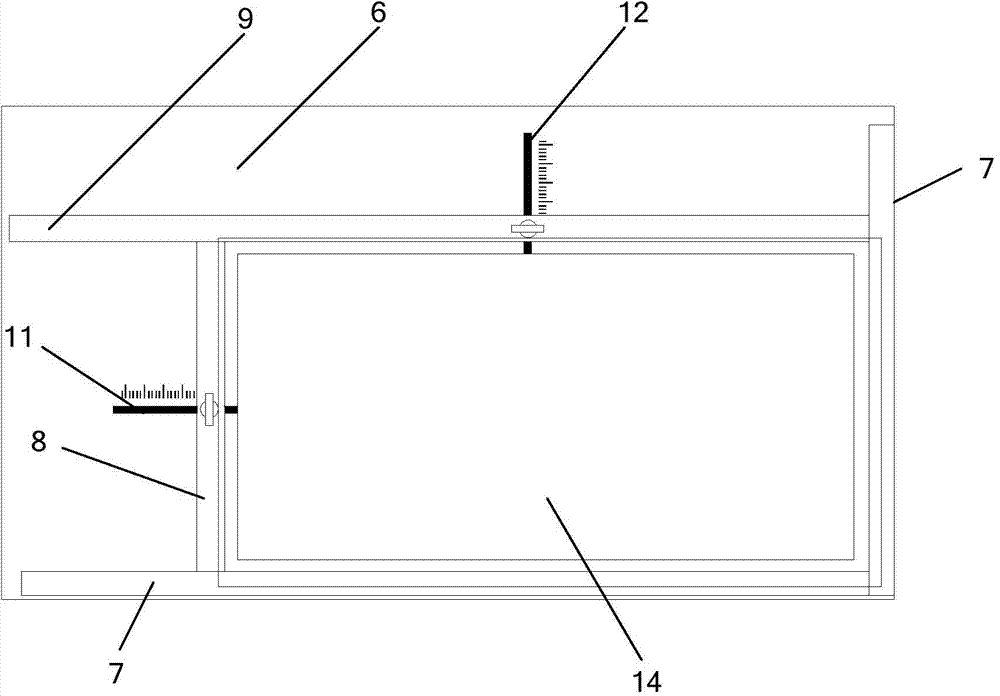

[0030] Such as figure 2 As shown, the present invention provides a backlight module material reliability test fixture, including a fixture base 6 and four fixture side frames, and the four fixture side frames are all arranged on the upper surface of the fixture base 6 , and are vertically connected to each other in turn to form a cavity structure. After the cavity structure of the test fixture is assembled, the material to be tested for the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com