Waterproof electronic equipment unit

An electronic equipment, waterproof technology, applied in the direction of electrical equipment structural parts, electrical components, electrical equipment shell/cabinet/drawer, etc. The device 42 has problems such as poor heat dissipation characteristics, and achieves the effects of not being in direct contact with water, suppressing effective space, and having a small and cheap structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0039] (1) Detailed description of the structure

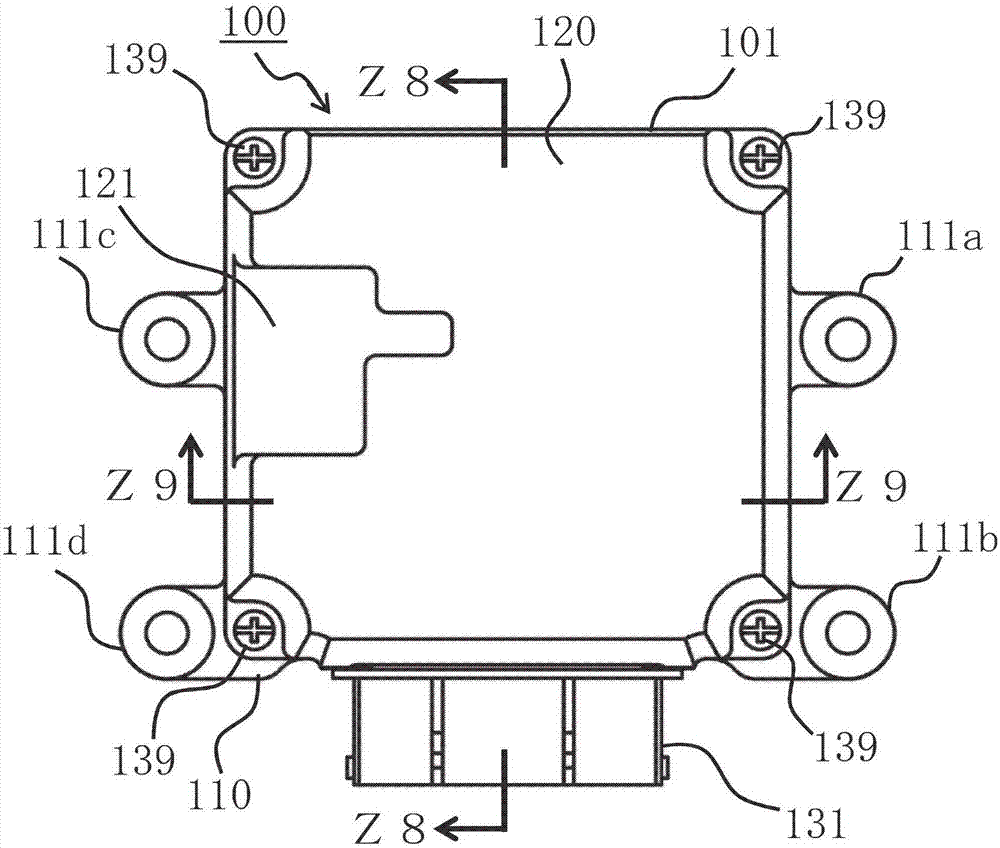

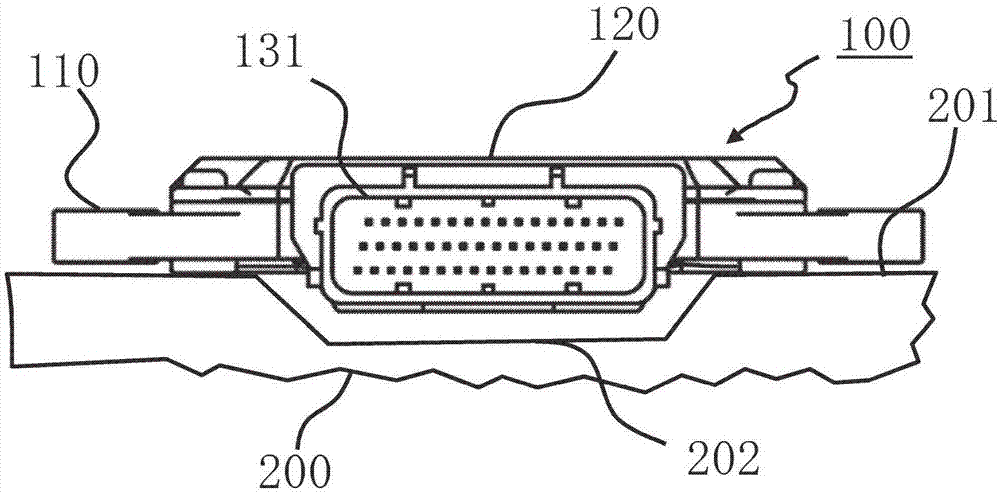

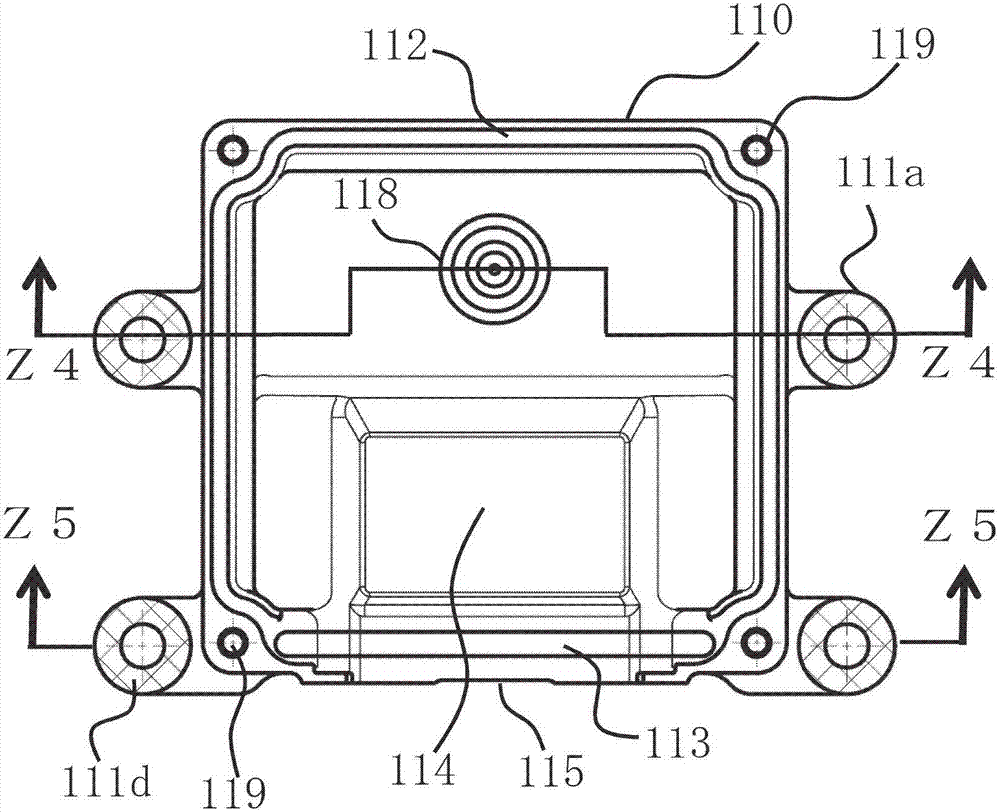

[0040]Next, a top appearance view of a waterproof electronic equipment unit according to an embodiment of the present invention, that is, will be sequentially described. figure 1 ,From figure 1 The appearance of the end face viewed from the mounting side of the middle connection shell is figure 2 , figure 1 The internal top view of the base is image 3 , image 3 The sectional view at the Z4-Z4 line is Figure 4 , image 3 The sectional view at the Z5-Z5 line is Figure 5 , figure 1 The internal top view of the middle cover is Figure 6 , Figure 6 The sectional view at the Z7-Z7 line is Figure 7 Be explained.

[0041] First, in the external view of the unit viz. figure 1 , figure 2 Among them, the waterproof electronic equipment unit 100 (hereinafter sometimes simply referred to as the unit) consists of a housing 101 and a circuit board 130 housed in the housing (refer to Figure 8 ), the casing 101 is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com