flexible clamping device

A clamping device and flexible technology, applied in the direction of workpiece clamping devices, manufacturing tools, etc., can solve the problems of poor versatility, achieve accurate and stable clamping, stable movement, and reduce the number of productions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

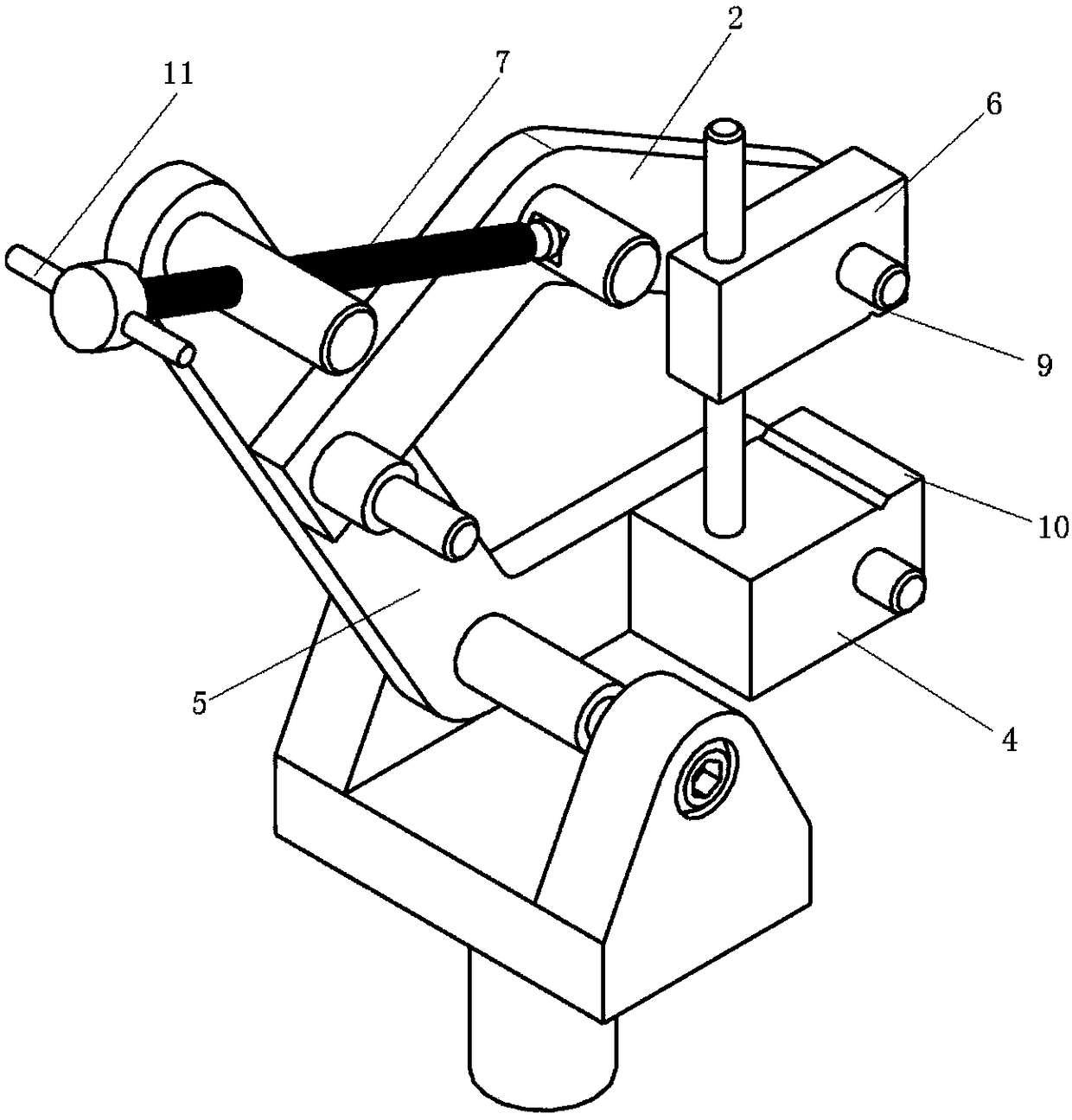

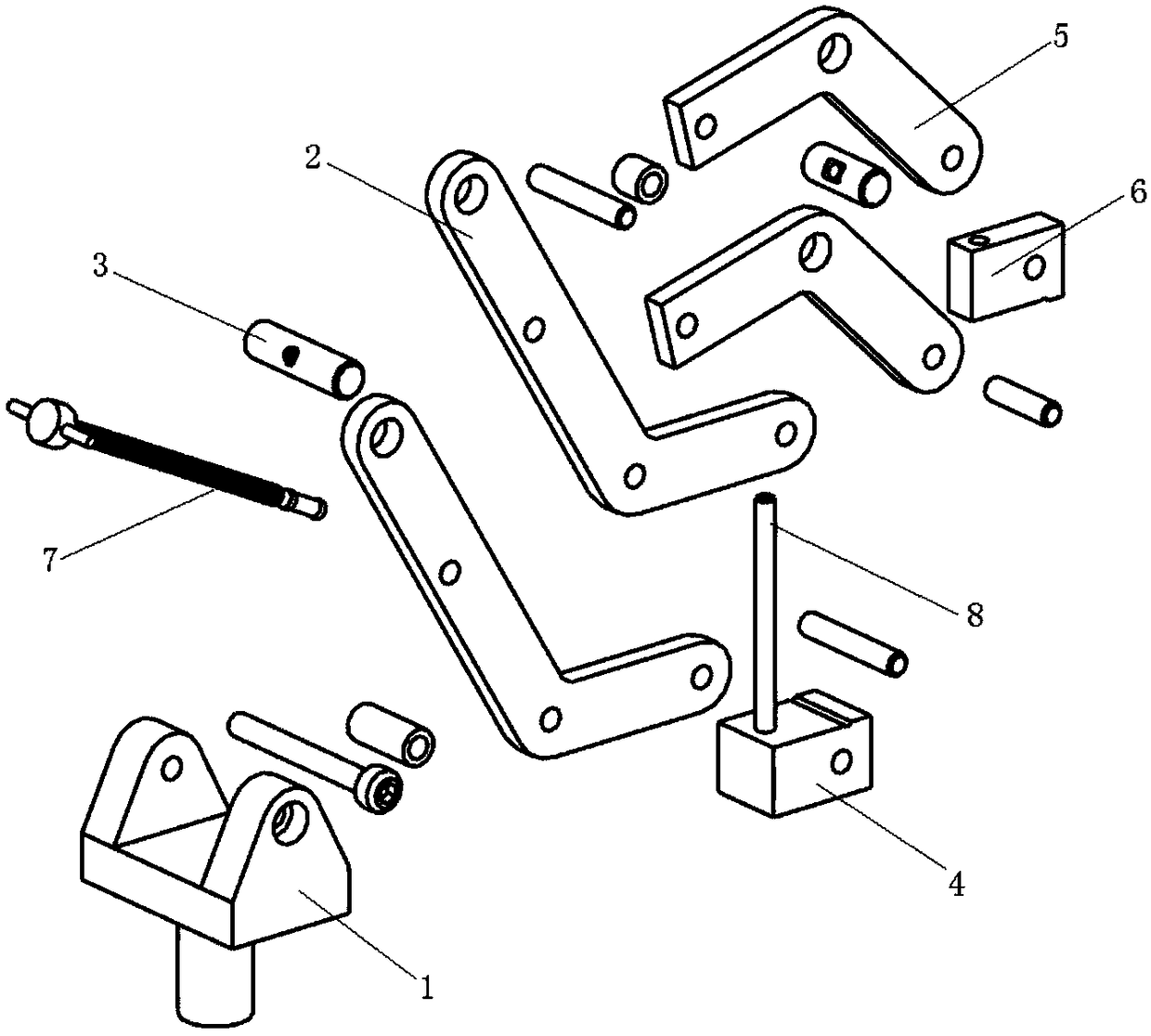

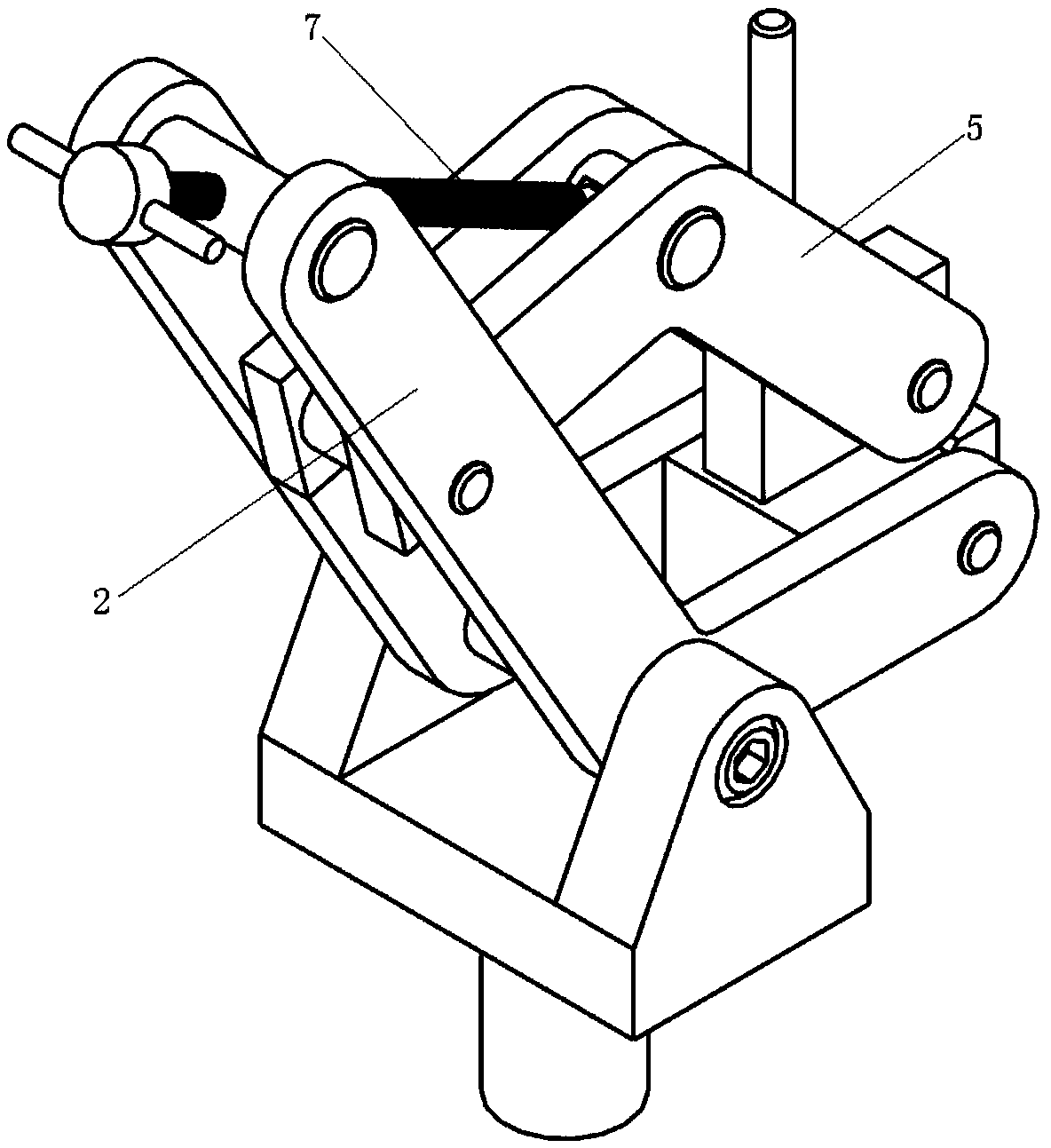

[0022] combine figure 1 with figure 2 As shown, a flexible clamping device provided for an embodiment of the present invention includes:

[0023] Base 1, which is used to support the device as a whole, base 1 includes a top support and a bottom insertion shaft in this scheme, the two sides of the support are provided with lugs, and the active frame 2 is rotatably installed between the two lugs; The connecting shaft is installed at the bottom of the support. When installing, the plug-in shaft is inserted into the corresponding round hole of the BASE plate of the inspection tool and fastened to the body of the inspection tool.

[0024] The main clamping group includes the active frame 2 and the drive nut 3 and the lower clamping block 4 installe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com