Wire transfer ladle

A transfer bag and wire technology, applied in the field of electric power equipment, can solve the problems of waste of iron wire and wire binding, easy loosening of cables, cumbersome binding process, etc., and achieve the effect of avoiding looseness and falling, improving the scope of application, and not easy to scatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

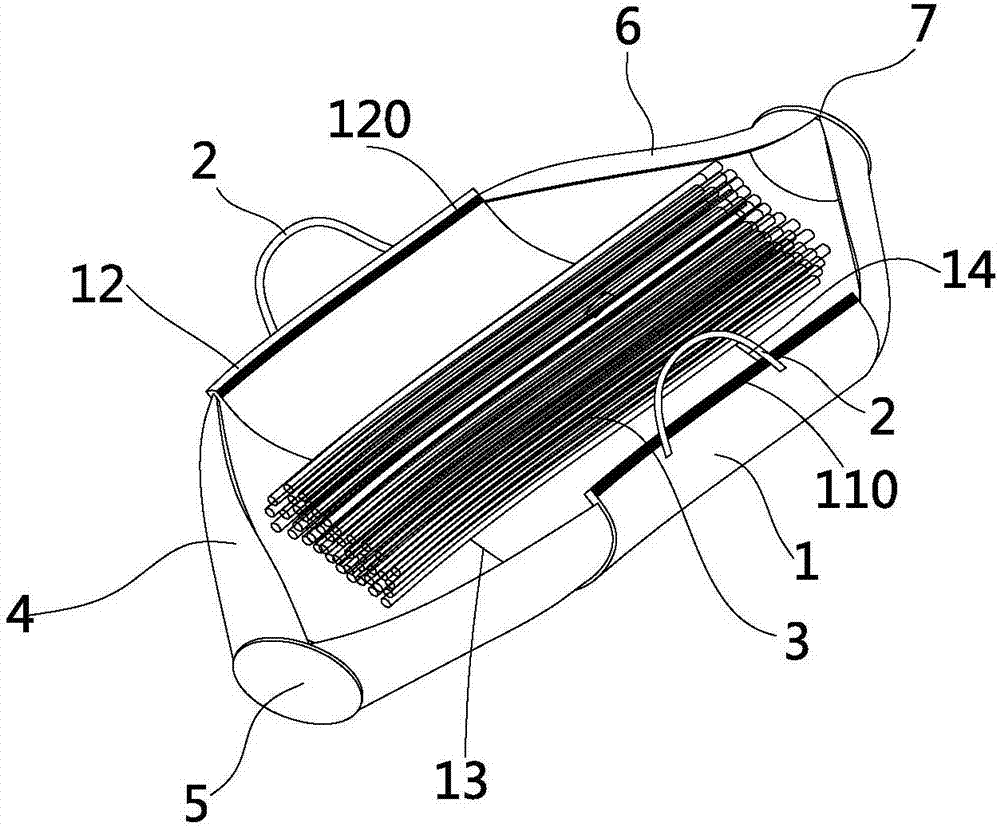

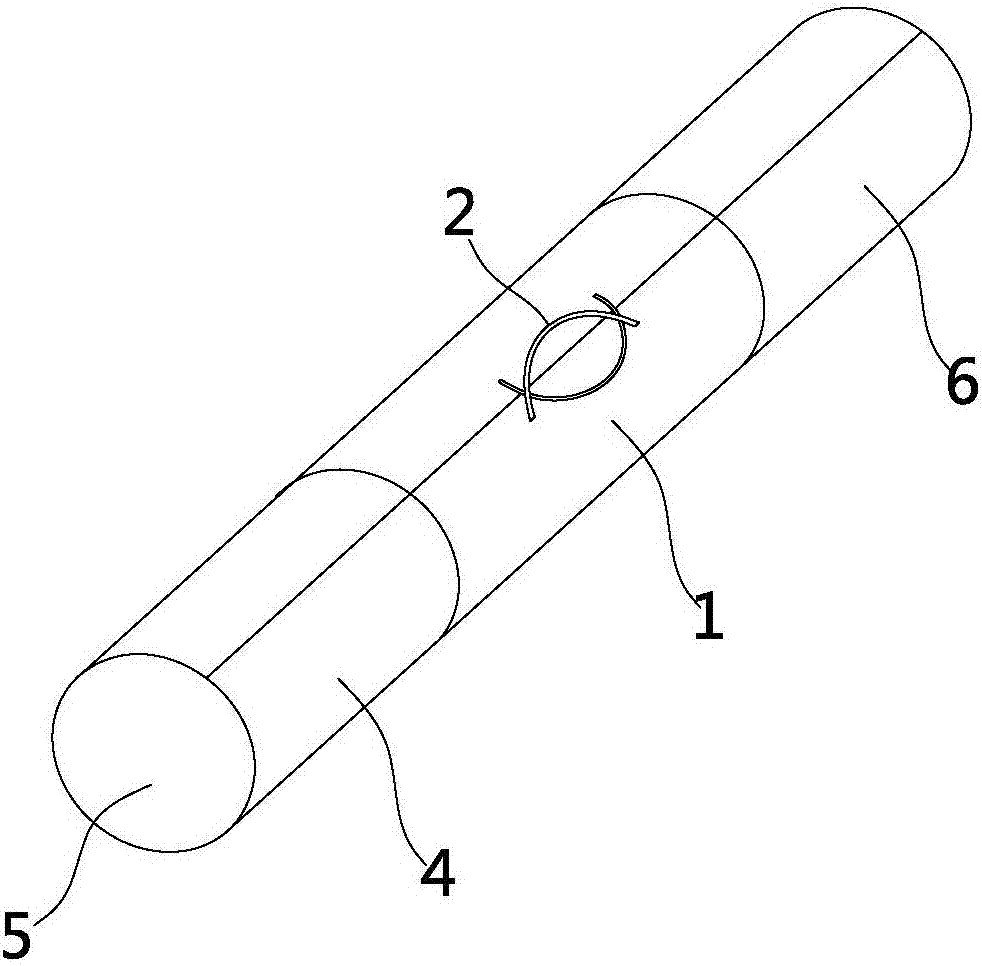

[0035] Such as Figure 1 to Figure 2 As shown, the wire transfer bag in this embodiment includes a flexible bag body 1, the flexible bag body 1 can be made of fabrics such as nylon cloth, fiber cloth or canvas, the flexible bag body 1 is in the shape of a rectangular sheet, and the flexible bag body 1 includes oppositely arranged The first side 11 and the second side 12, and the third side 13 and the fourth side 14 arranged between the first side 11 and the second side 12, the third side 13 and the fourth side The sides 14 are arranged oppositely, wherein the handle 2 is provided on the first side 11 and the second side 12, and the first side 11 and the second side 12 in this embodiment are detachably connected, for example, the first side 11 It is connected with the second side 12 by Velcro or buckle or zipper or snap button or hasp. In this embodiment, Velcro is preferred. Velcro includes Velcro hook surface and Velcro rough surface. Specifically, Velcro rough surface 110 i...

Embodiment 2

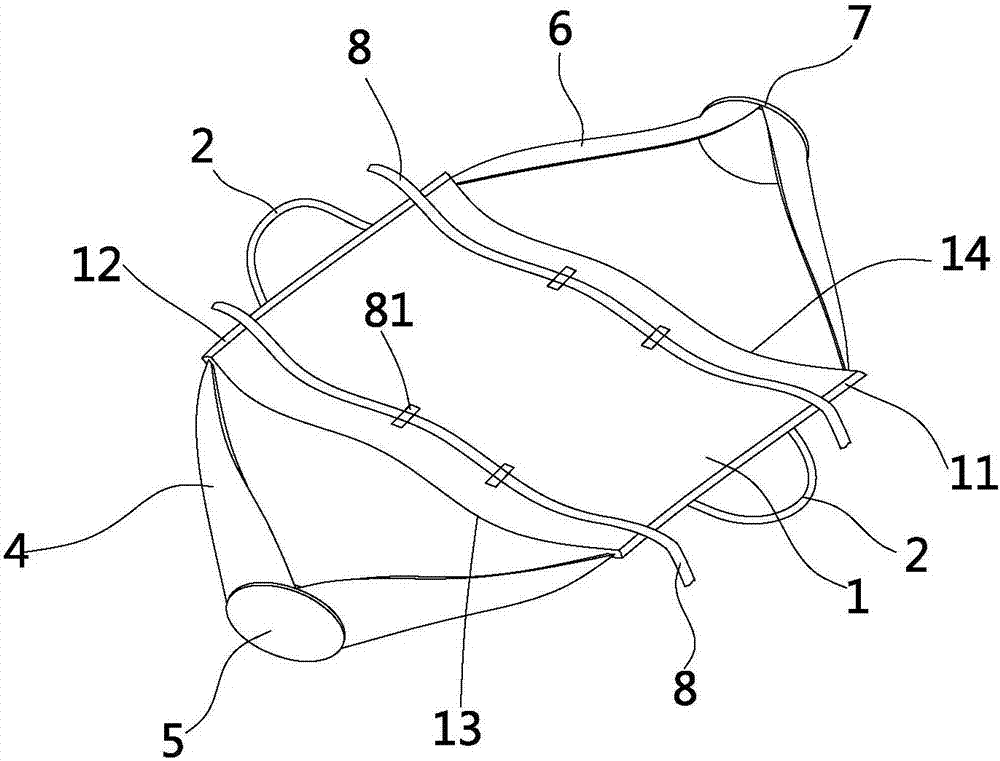

[0040] Such as Figures 3 to 4 As shown, the present embodiment is a further improvement on the first embodiment. On the inner surface of the flexible package body 1, several restraint belts 8 perpendicular to the first side 11 are provided, and on the inner surface, there are a number of restraint belts 8 for fixing restraints. At least two fixed points 81 of the strap 8, the two ends of the strap 8 are connected by Velcro or buckle or snap or buckle, so that between the two fixed points 81, the strap 8 and the flexible package A space is formed between the inner surfaces of 1, which can be used to fix a part of the wire 3, and this part of the wire 3 will not be scattered when the connection between the first side 11 and the second side 12 on the flexible enclosure 1 fails; After the flexible wrapping body 1 is crimped, the wires 3 wrapped by the flexible wrapping body 1 can be further fixed by the restraining band 8, so as to improve the effect of organizing and storing the...

Embodiment 3

[0043] Such as Figure 5 As shown, this embodiment is a further improvement to Embodiment 1 or 2. The flexible package 1 in this embodiment includes two layers of cloth sheets 10, and elastic fillers 101 are filled between the two layers of cloth sheets 10, and the elastic fillers It can be silica gel or sponge, etc. In this way, the elastic filler 101 can play the role of shock absorption and cushioning, and effectively prevent the wire 3 from being bumped by the outside.

[0044] In addition, the inner surface of the flexible package body in this embodiment is provided with a wear-resistant layer 102, the wear-resistant layer 102 is a wear-resistant material such as nylon cloth or canvas, and the wear-resistant layer 102 can ensure that the flexible package body 1 can be curled. Enhancing the anti-friction ability can also effectively prevent the wire material 3 from being worn on the flexible package body 1 and prolong the service life of the wire transfer package. The out...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap