Directional rod conveying device for copper rod rolling mill

A copper rod and rolling mill technology, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve the problems of copper rod winding in one body and reduce the working efficiency of copper rod rolling mill, so as to ensure the product appearance and quality, and simple structure , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

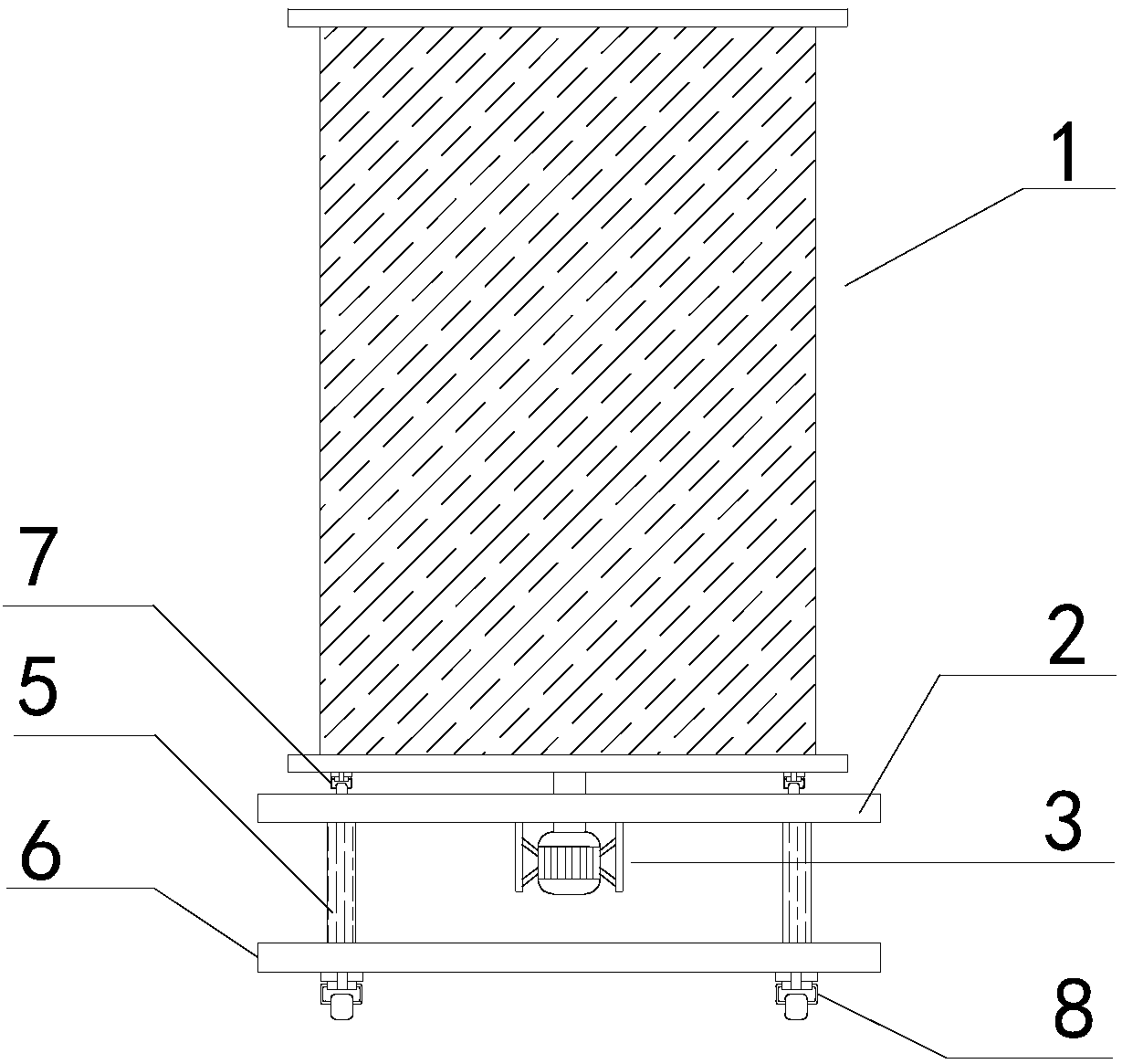

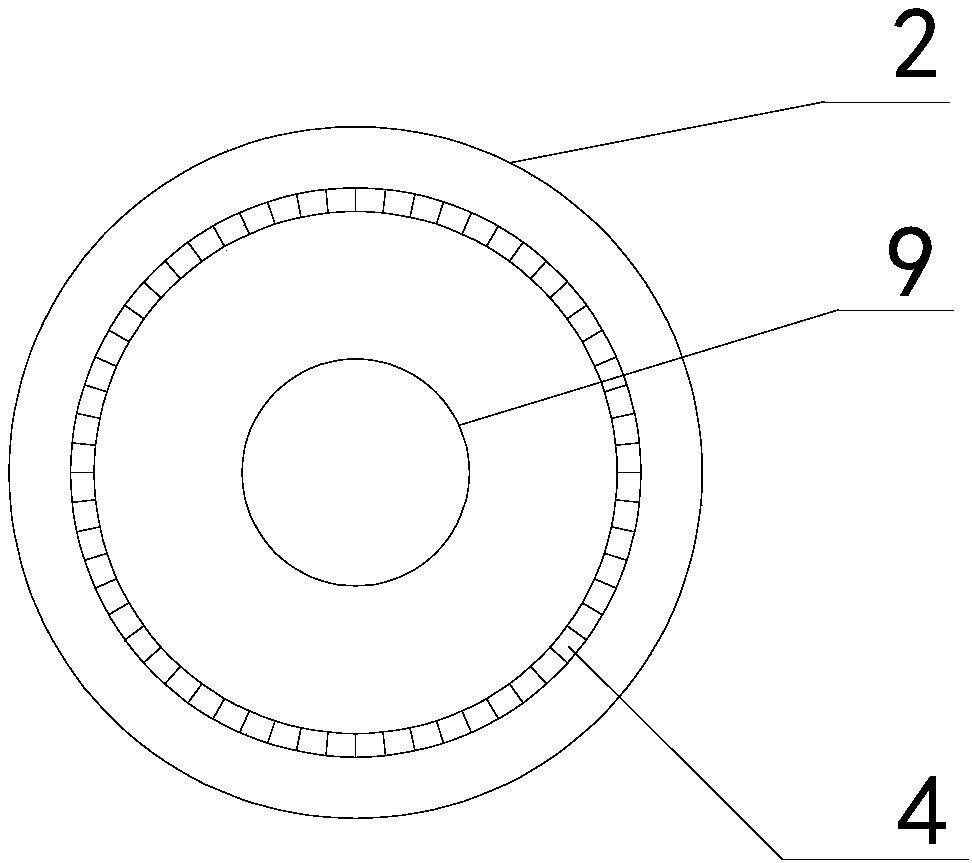

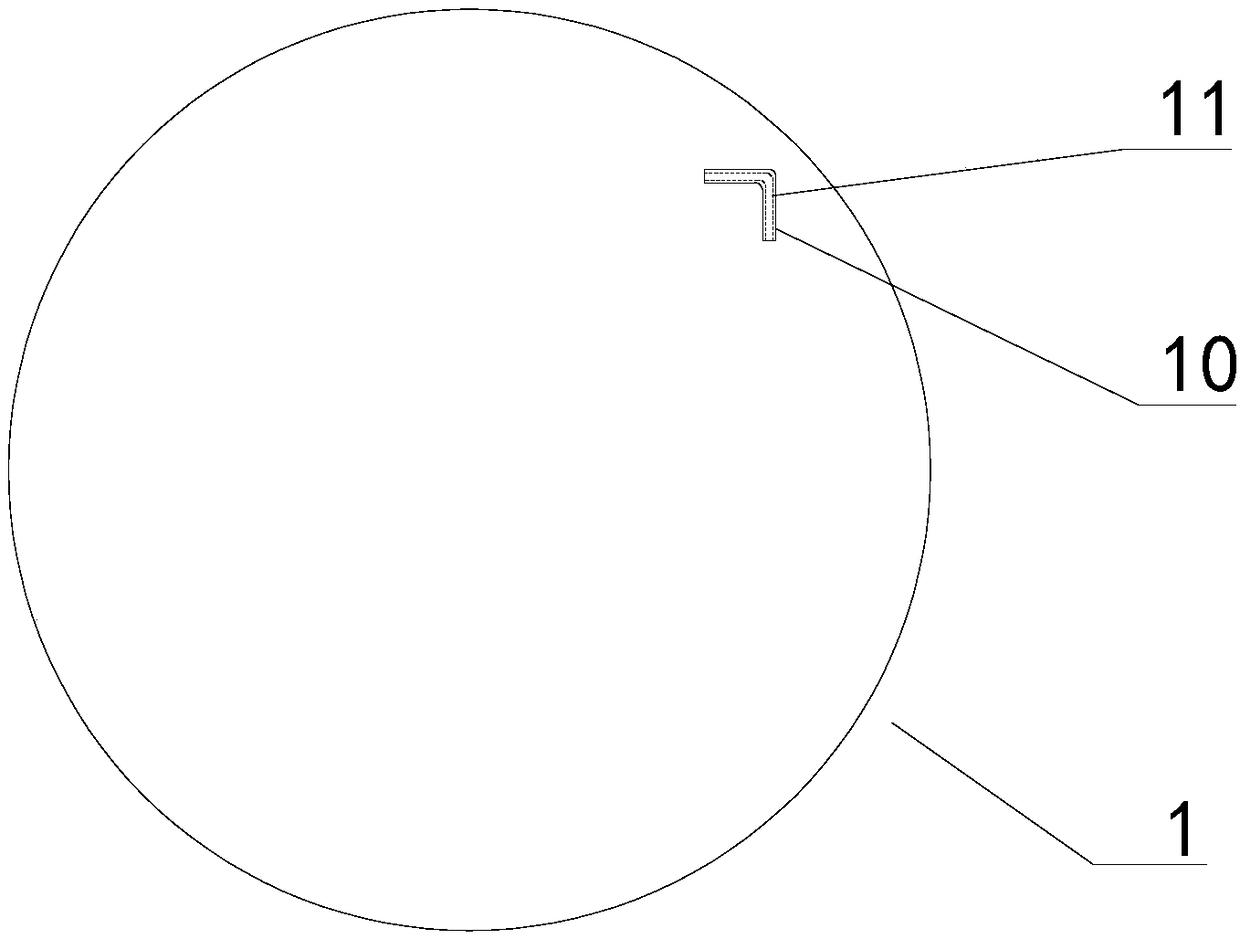

[0024] A directional rod feeding device for a copper rod rolling mill, comprising a bearing base 2, a through hole 9 is opened in the middle of the bearing base 2, a driving motor 3 is fixed on the bottom of the bearing base 2 through a mounting plate, the mounting plate and the bearing base 2 and The drive motors 3 are fixedly connected by screws. The output shaft of the driving motor 3 passes through the through hole 9 and is connected with the barrel 1 for winding the copper rod.

[0025] The working principle is as follows: before starting the copper rod rolling mill, the copper rod is wound on the barrel 1 from bottom to top, and after the winding is completed, the head of the copper rod is brought into the rolling mill. Turn on the copper rod rolling mill, and start the drive motor 3 at the same time, the drive motor 3 rotates, and drives the cylinder 1 connected to it to rotate, so that the copper rod wound on the cylinder 1 is separated from the cylinder 1 . The devic...

Embodiment 2

[0027] On the basis of Embodiment 1, swivel casters 7 are provided at the bottom of the cylinder body 1 , and slide rails 4 matched with the swivel casters 7 are provided on the bearing seat 2 . During the rotation process of the cylinder body 1 driven by the drive motor 3 , the swivel casters 7 at the bottom of the cylinder body 1 move on the slide rail 4 . Through this operation, the driving force required by the driving motor 3 to drive the barrel 1 is reduced, thereby reducing the consumption of material resources and improving the working efficiency of the entire device.

Embodiment 3

[0029] On the basis of any of the above-mentioned embodiments, the lower side of the bearing seat 2 is also provided with a lifting mechanism 10. The lifting mechanism 10 includes a cylinder 5 and a base 6 for carrying the cylinder 5. One end of the cylinder 5 is connected with the bearing seat 2, and the cylinder 5 The other end of the cylinder is connected with the base 6, and the connection modes between the cylinder 5 and the bearing seat 2 and the base 6 are all connected by screws. When the copper rod wound on the upper half of the cylinder 1 is separated from the cylinder 1, the cylinder 5 pushes the internal piston rod to move outward, so that the bearing seat and the components arranged on the bearing seat move upward together. This operation facilitates the delivery of copper rods to the copper rod rolling mill, thereby improving the working efficiency of the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com