Antitheft lock head with stepped-shaped inner bolt holes

A marble hole and step-shaped technology is applied in the field of anti-theft lock heads, which can solve the problems of poor safety performance of anti-theft lock heads, and achieve the effects of increasing the difficulty of theft lock, excellent anti-theft performance, and improving anti-theft performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

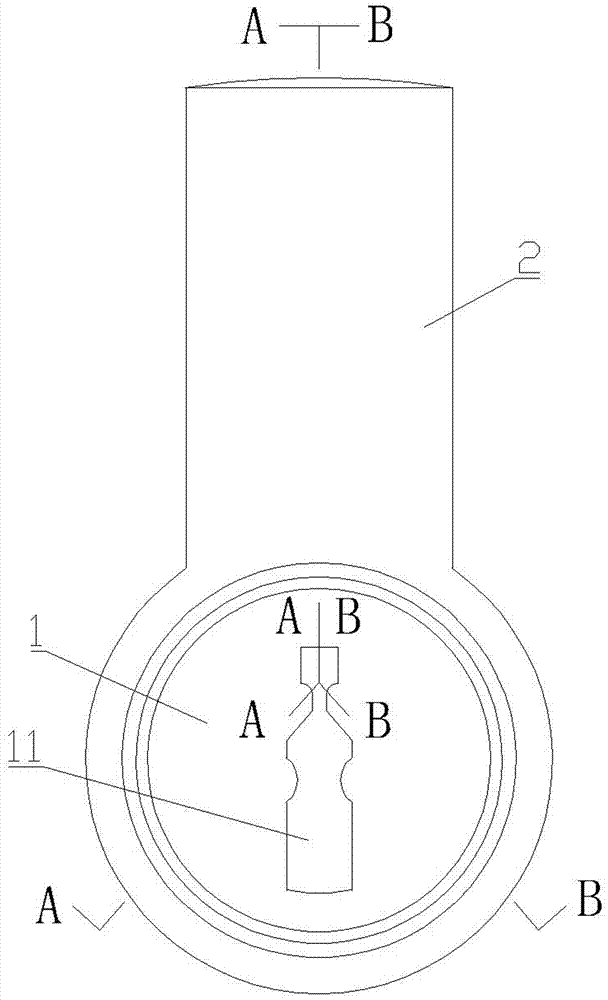

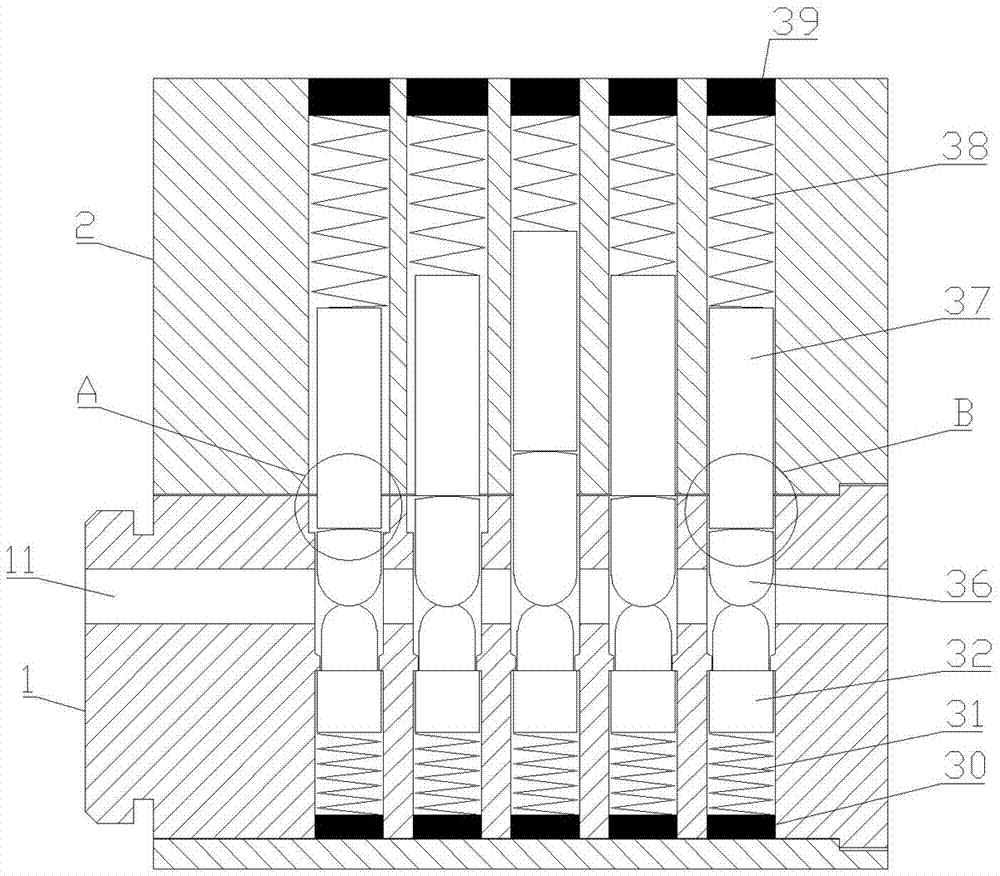

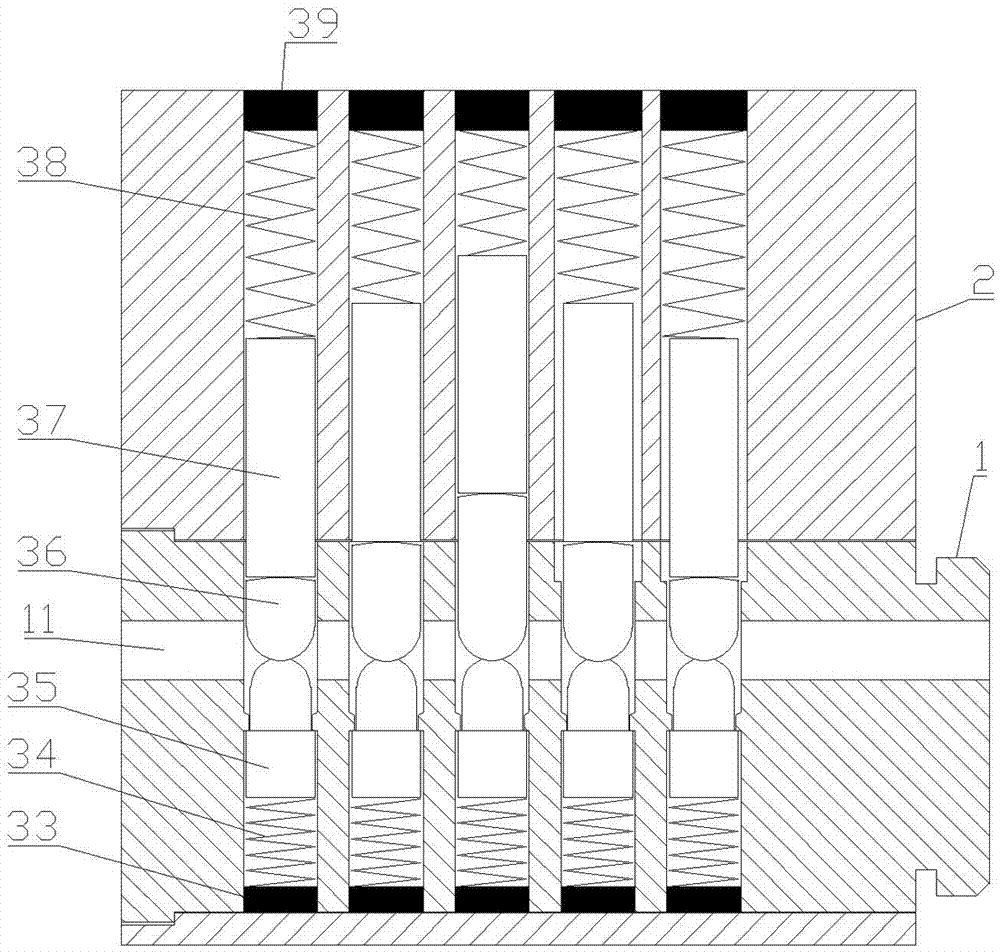

[0035] Such as Figure 1-7 As shown, the anti-theft lock head with a stepped inner pin hole includes a lock cylinder 1, a lock cylinder sleeve 2 and a pin mechanism.

[0036] The lock cylinder sleeve 2 is provided with a lock cylinder hole 21 and an outer pinhole 22, and the outer pinhole holes 22 are distributed along the axial direction of the lock cylinder sleeve 2, and the number is five, which penetrate from the outer surface of the lock cylinder sleeve 2 to the lock cylinder in hole 21.

[0037] Lock cylinder 1 is provided with key hole 11, left inner mounting hole 12, right inner mounting hole 13 and inner marble hole 14, and left inner mounting hole 12 and right inner mounting hole 13 are symmetrically arranged on both sides of key hole 11, both They all penetrate from the outer surface of the lock core 1 to the key hole 11, and the inner pinholes 14 are distributed along the axial direction of the lock core 1, and there are five in number, which penetrate from the ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com