vacuum cleaner robot

A technology of vacuum cleaners and robots, which is applied in the direction of robot cleaning machines, cleaning equipment, cleaning devices, etc., can solve the problems of low power of motor fan unit, small dust absorption capacity, etc., and achieve the effect of high volume flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

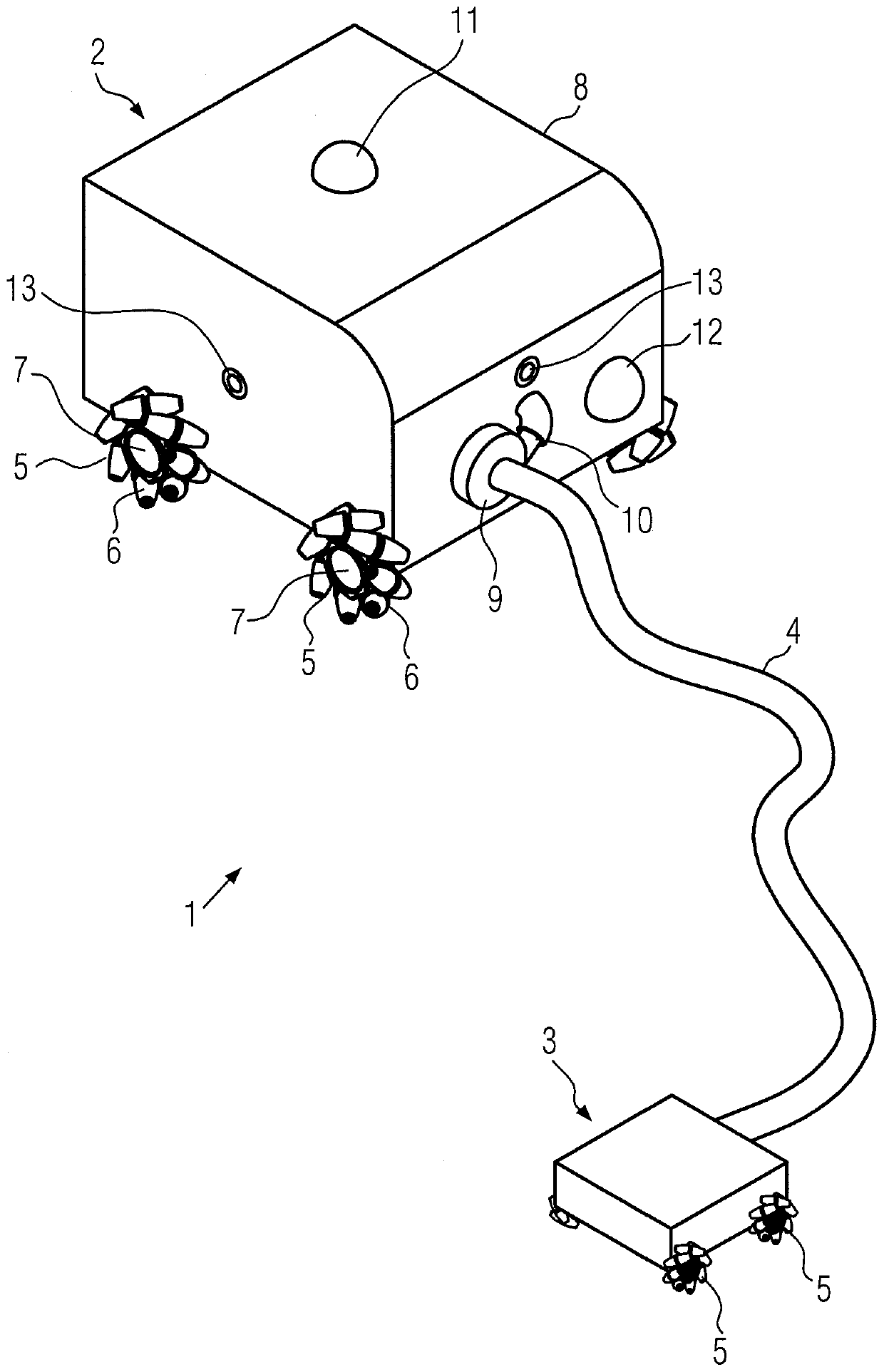

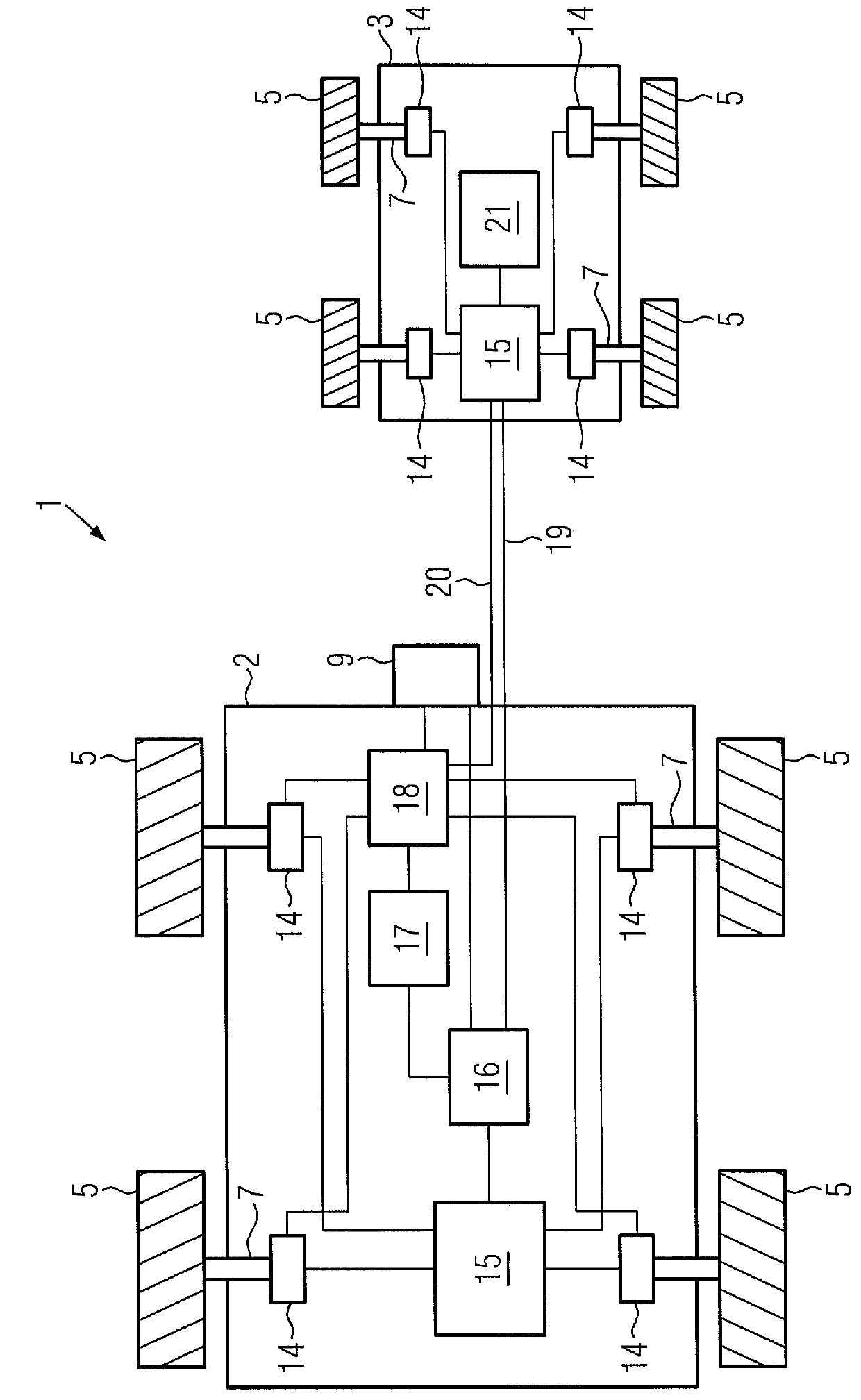

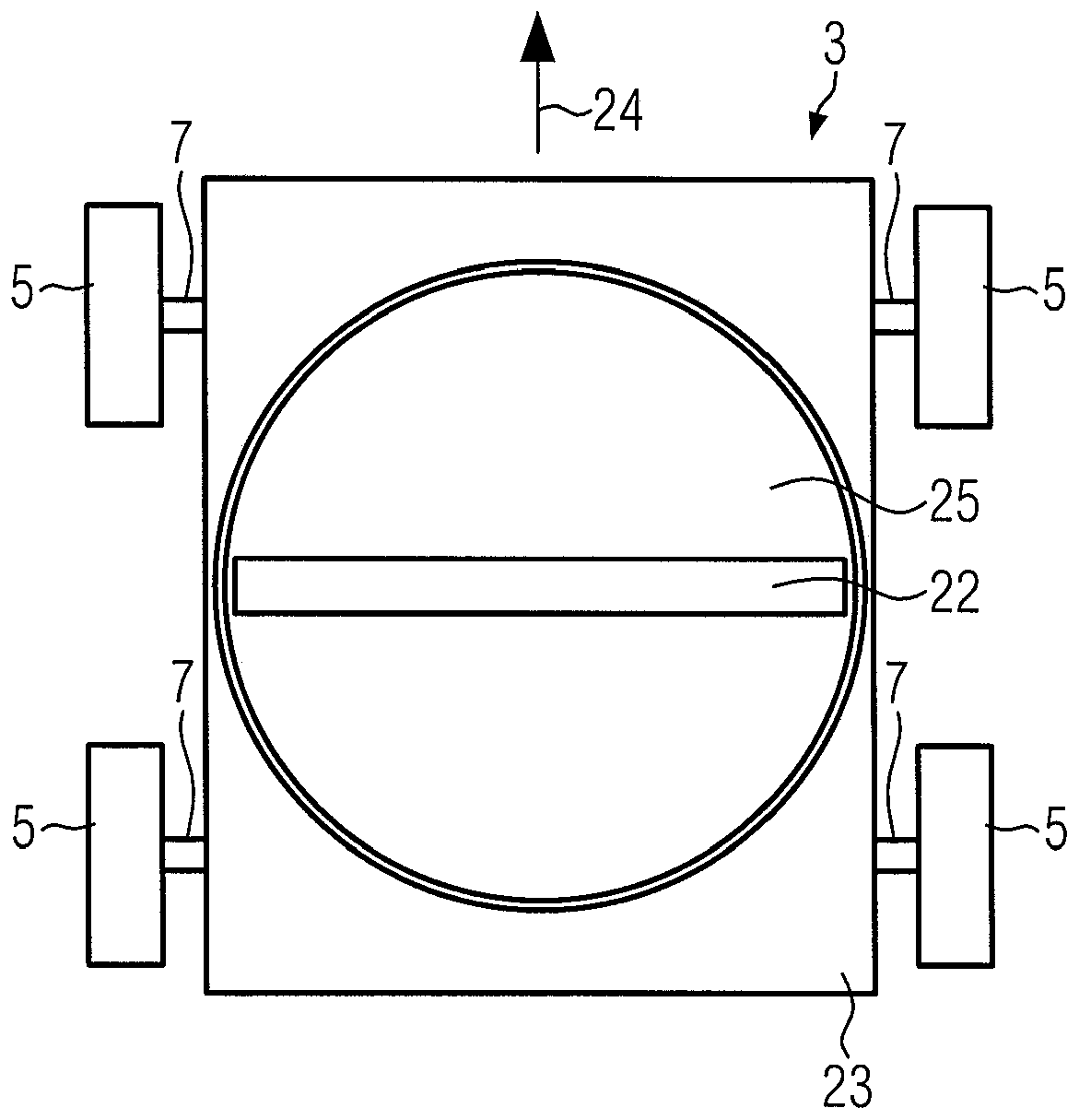

[0089] figure 1 A schematic diagram of a first embodiment of a vacuum cleaner robot 1 is shown. The shown vacuum cleaner robot 1 comprises a dust collection unit 2 and a floor nozzle 3 connected to the dust collection unit 2 via a flexible suction hose 4 . The vacuum cleaner robot 1 thus has a two-part design, i.e. the dust collection unit 2 and the floor nozzle 3 define a single unit, the dust collection unit 2 and the floor nozzle 3 being connected to each other only by means of the suction hose 4 .

[0090] The dust collection unit 2 is supported on four wheels 5, all of which are configured as omnidirectional wheels. Each omni wheel 5 has a plurality of rotatably mounted rollers 6 provided on its circumference. The axes of rotation of said rollers 6 are all non-parallel to the wheel axis 7 of the corresponding omni wheel. For example, the axes of rotation of the rollers may be at an angle of 45° relative to the respective wheel axes. The surface of the roll or roll bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com