Wood chipper material blocking prevention device

A chipper and material jam prevention technology, which is applied in wood processing equipment, manufacturing tools, etc., can solve the problems of reducing the use efficiency of chippers and chipper material jams, and achieves the solution of material jams and minor material jams. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

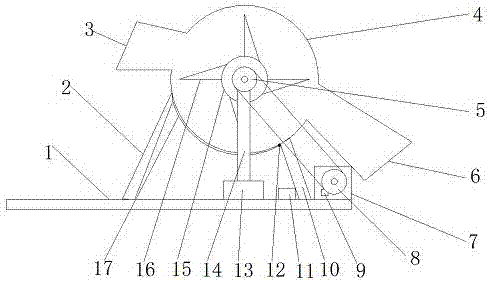

[0014] The technical solution will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments. Apparently, the described embodiments are only some of the embodiments of the technology, but not all of them.

[0015] refer to figure 1 , an anti-jamming device for a wood chipper, comprising a workbench 1, a drive motor 7 connected to the top outer wall of one end of the workbench 1 through bolts, the output shaft of the drive motor 7 is connected to a first pulley 8 through a movable pin, and the drive motor 7 is close to One side of the pulley is connected with a speed sensor 9 by screws, the other end of the workbench 1 is welded with a first support foot 2 on the top outer wall, and the workbench 1 is welded with a second support foot 10 near the top outer wall of the drive motor 7, the first support foot 2 and the second The top of the second support leg 10 is welded with a cutting bin 4, the cutting bin 4 is provided with a fee...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap