Wire coil capable of intelligently and automatically distributing bundling rope by using wire roller for large-scale distribution box

A technology for automatic distribution and power distribution cabinets, applied in the direction of binding objects, binding materials, packaging/binding items, etc., can solve problems such as waste of manpower, affecting cable transportation, and increasing labor load of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

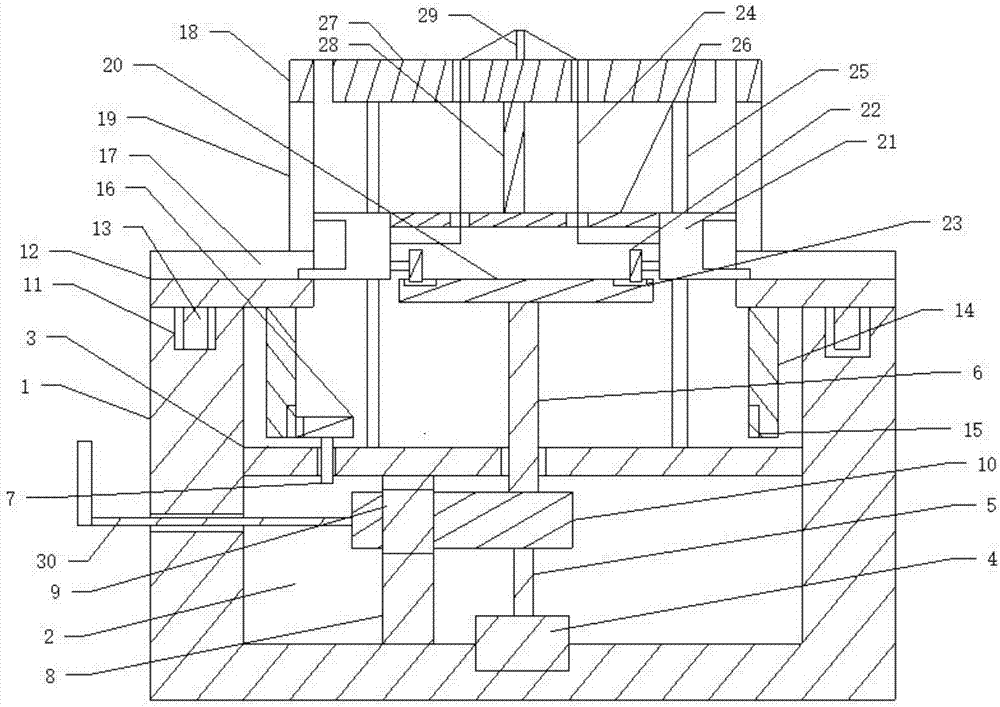

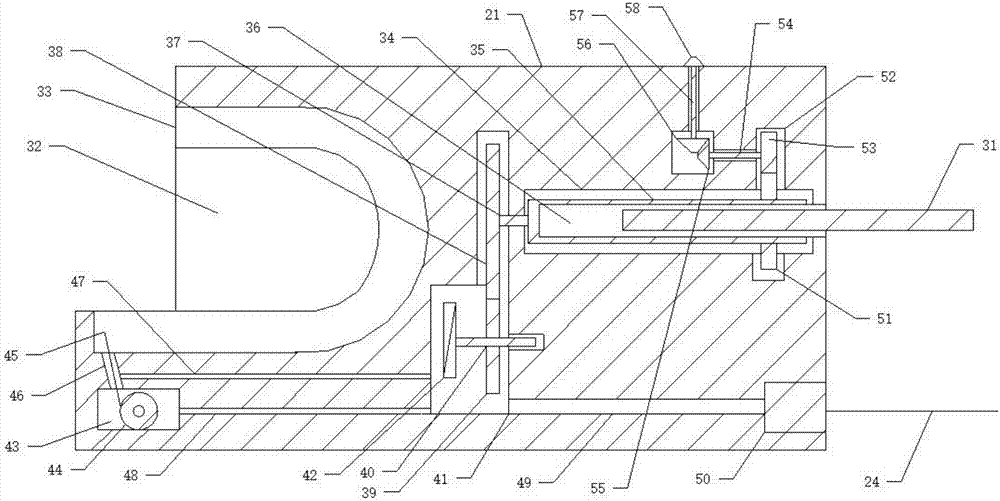

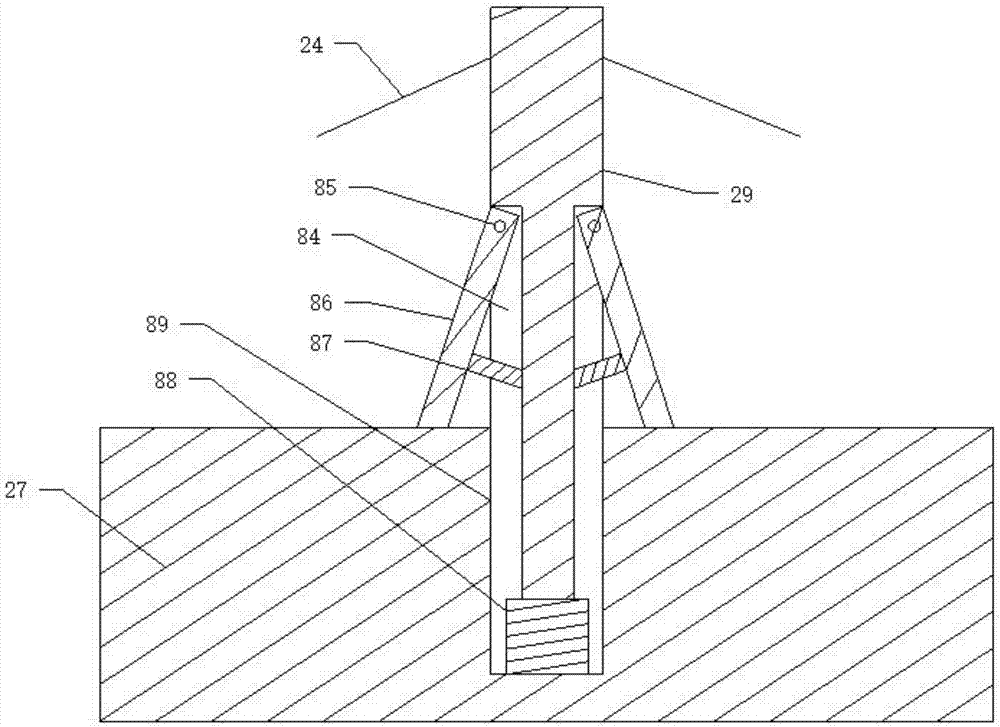

[0038] Such as Figure 1 to Figure 10As shown, a large-scale power distribution cabinet intelligent wire roller automatically distributes the binding rope reel, including a fixed base 1, and a base groove 2 is arranged on the fixed base 1, and a connection is arranged in the base groove 2 The first support plate 3 on the fixed base 1 is provided with a first rotating shaft 5 driven by a motor 4 in the base groove 2, and a rotating second rotating shaft 6 and a third rotating shaft 6 are arranged on the first support plate 3. The rotating shaft 7, the fixed base 1 is provided with a rotating branching turntable 12, the branching turntable 12 is provided with a branching support cylinder 18, and the branching support cylinder 18 is provided with cross-corresponding supporting cylinders. groove 19, the third rotating shaft 7 drives the line dividing turntable 12 to rotate. The fixed base 1 is arranged in a cylindrical shape, and the fixed base 1 is provided with a base groove 2,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com