Pneumatic tire for passenger cars

A technology for pneumatic tires and vehicles, applied to the reinforcement layer of pneumatic tires, vehicle parts, tire parts, etc., can solve problems such as damage to steering stability, difference in steering force, oversteer, etc., to reduce load dependence, reduce The effect of small load dependencies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

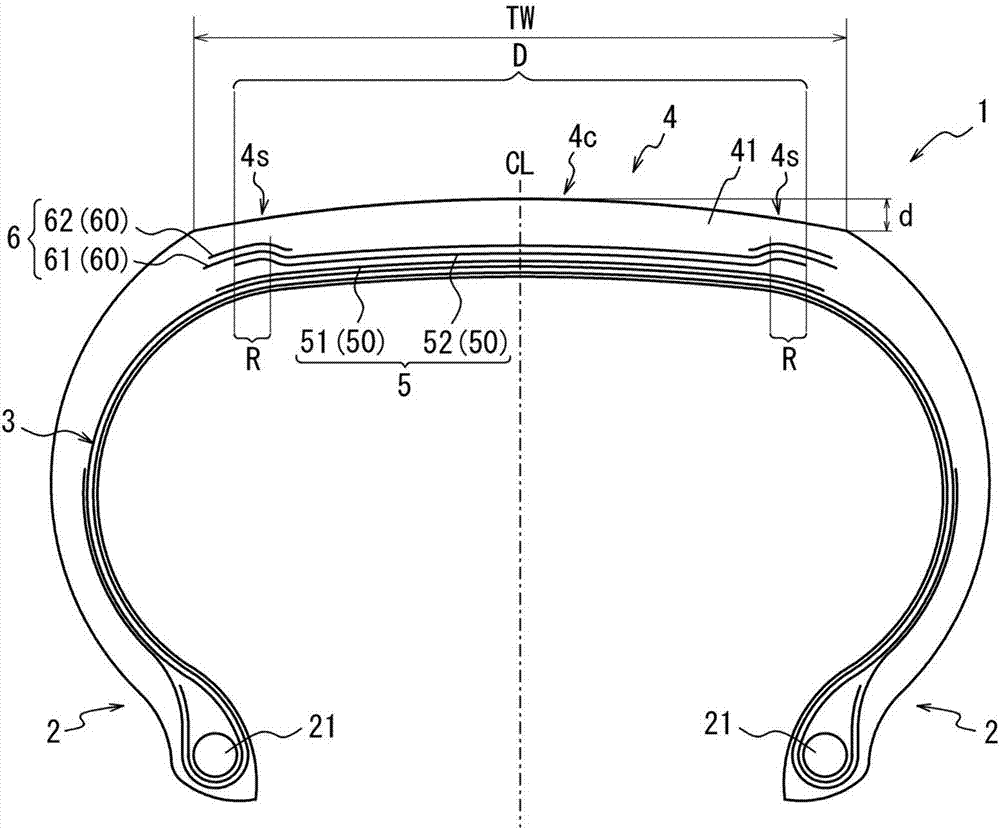

Embodiment 1

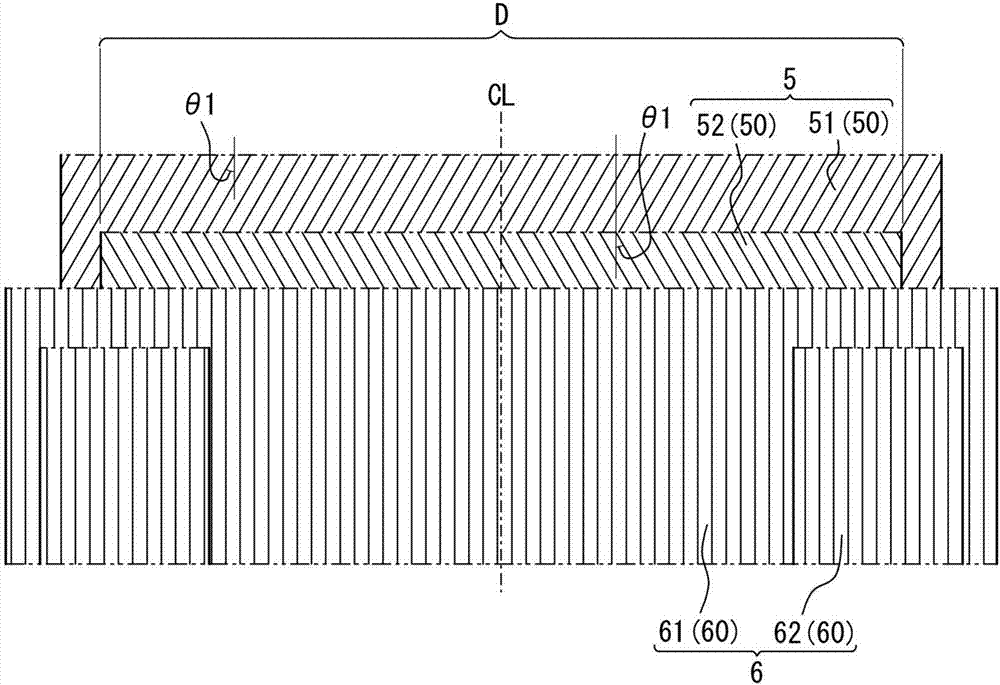

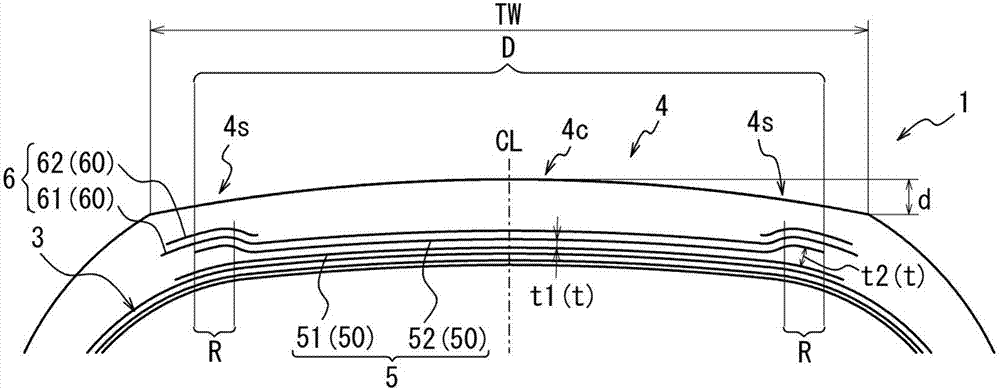

[0065] The tire of Example 1 has a tire size of 225 / 50R17, and includes a main belt formed of two slanted belt layers (first and second slanted belt layers) in which cords cross each other between layers, and sets A reinforcing belt on the outer side in the tire radial direction of the main belt. In addition, the reinforcing belt is formed of a first circumferential belt layer and a pair of second circumferential belt layers, wherein the first circumferential belt layer is provided spanning from the tire equatorial plane of the tread portion to the shoulder side, and a pair of second circumferential belt layers The second circumferential belt layer is provided outside the first circumferential belt layer in the tire radial direction, on shoulders on both sides in the tire width direction of the tread portion, and separated from each other. In addition, the thicknesses, etc., of the shoulder portion and the center portion between the cords of the two inclined belt layers are as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com