Tobacco packet conveying channel of hard box packing machine with online detecting and eliminating functions

A technology of conveying channel and packaging machine, which is applied in the direction of packaging cigarettes and cigars, etc., which can solve the problems of heavy labor, low work efficiency, and inability to open the box cover, and achieve the effect of reducing labor and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will now be described in further detail with reference to the drawings.

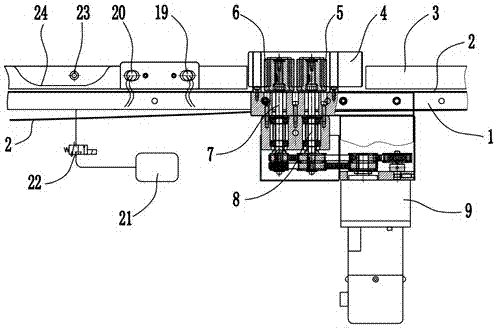

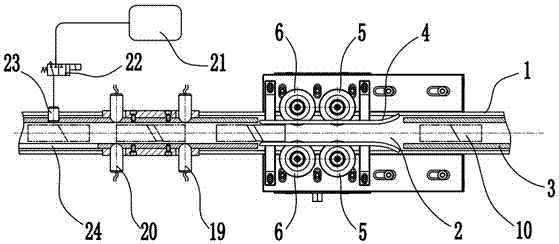

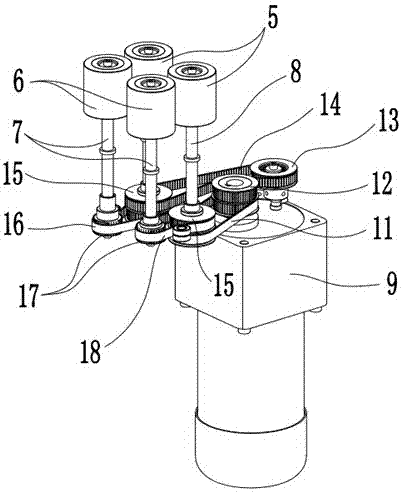

[0027] Such as Figure 1 to Figure 5 As shown, the cigarette packet conveying channel of the hard box packaging machine capable of online box lid separation detection includes a supporting bridge 1 located at the bottom of the cigarette packet conveying channel 1, baffles 3 located on both sides of the supporting bridge 1, and two baffles 3 Between the conveyor belt 2. A box cover separation device, a detection device and a waste cigarette package removal mechanism are sequentially installed on the cigarette packet conveying path along the conveying direction of the conveyor belt 2. The box cover separation device includes two pairs of differential transmission rollers and driving the differential transmission roller to convey along Belt 2 rotating transmission mechanism in the conveying direction. The box cover separating device is installed at a gap of the two baffles 3, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com