Rotor axial force measurement device and measurement method

A technology of measuring device and measuring method, which is applied in the direction of measuring device, force/torque/work measuring instrument, instrument, etc., can solve the problem that the axial force of the rotor cannot be measured, and can overcome the inability to measure the axial force and simplify the axial force. Measurement system, the effect of large-scale promotion and application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

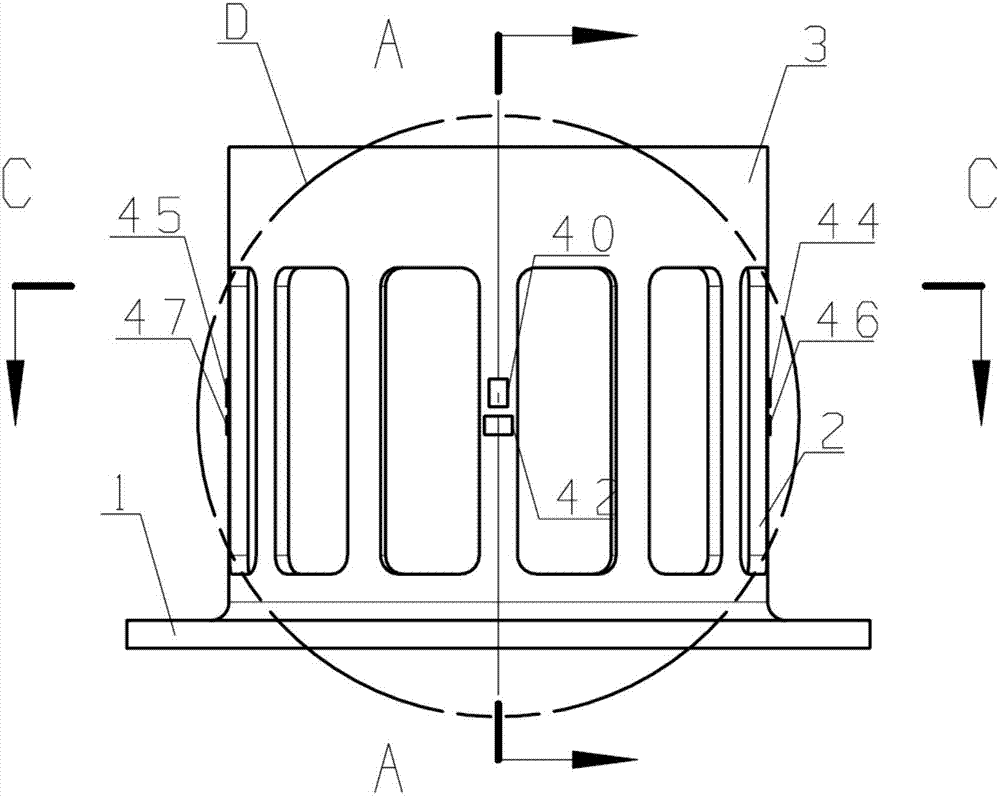

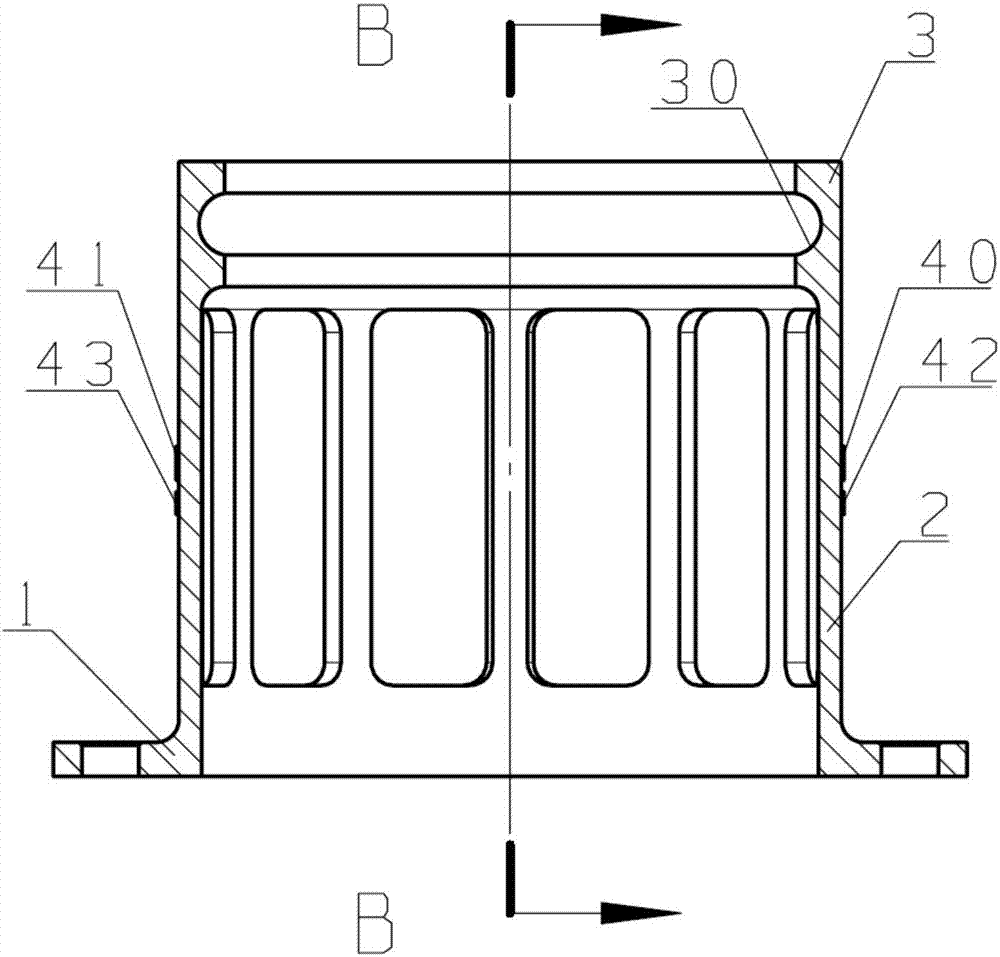

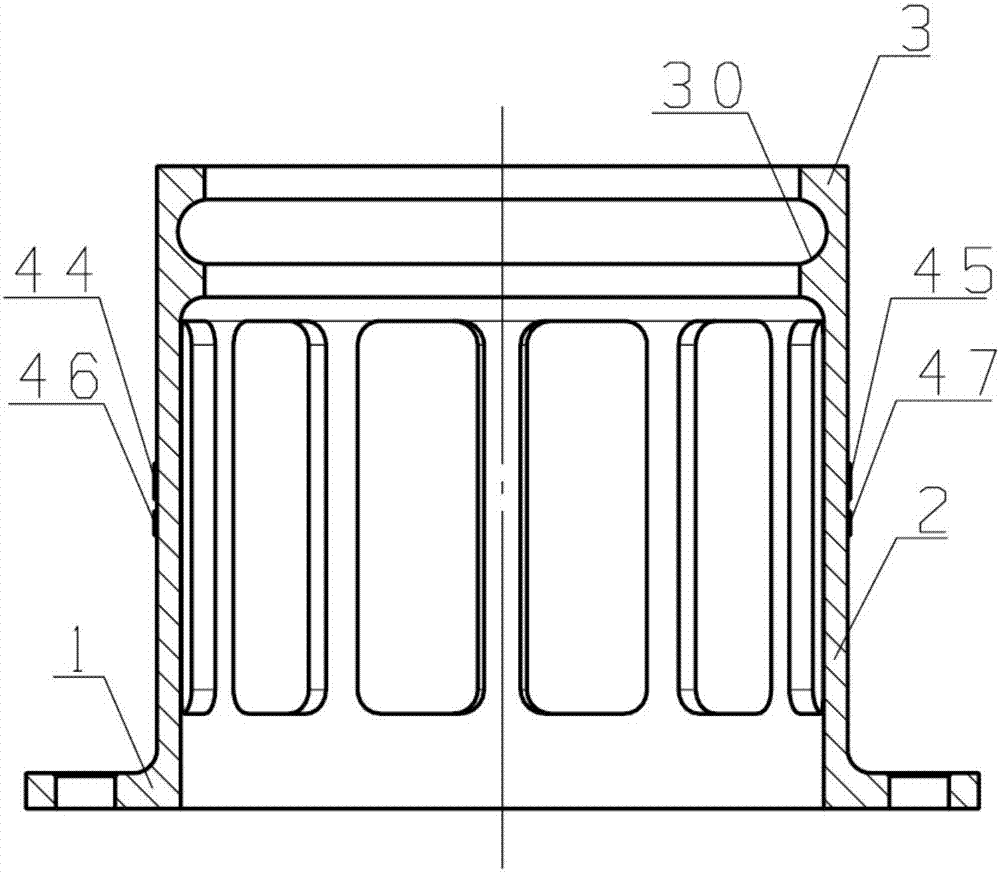

[0035] During the working process of the aero-engine, the compressor rotor compresses the gas to do work, which increases the gas pressure ratio, and the gas in turn has a forward reaction force on the blades, and these reaction forces act on the ball bearings through the rotor. Instead, the gas pushes the turbine blades to do work, and the turbine rotor experiences a backward force. For the rotor of the complete aircraft engine, the axial force of the rotor is the resultant force of the forward axial force acting on the compressor rotor and the backward axial force acting on the turbine rotor. The axial force of the rotor must be controlled within a certain range, neither too large nor too sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com