Conveying device for car ceiling production

A transmission device and car roof technology, which is applied in transportation and packaging, metal processing, metal processing equipment, etc., can solve problems such as high labor intensity, scratches on the car roof, and collisions with external objects, and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

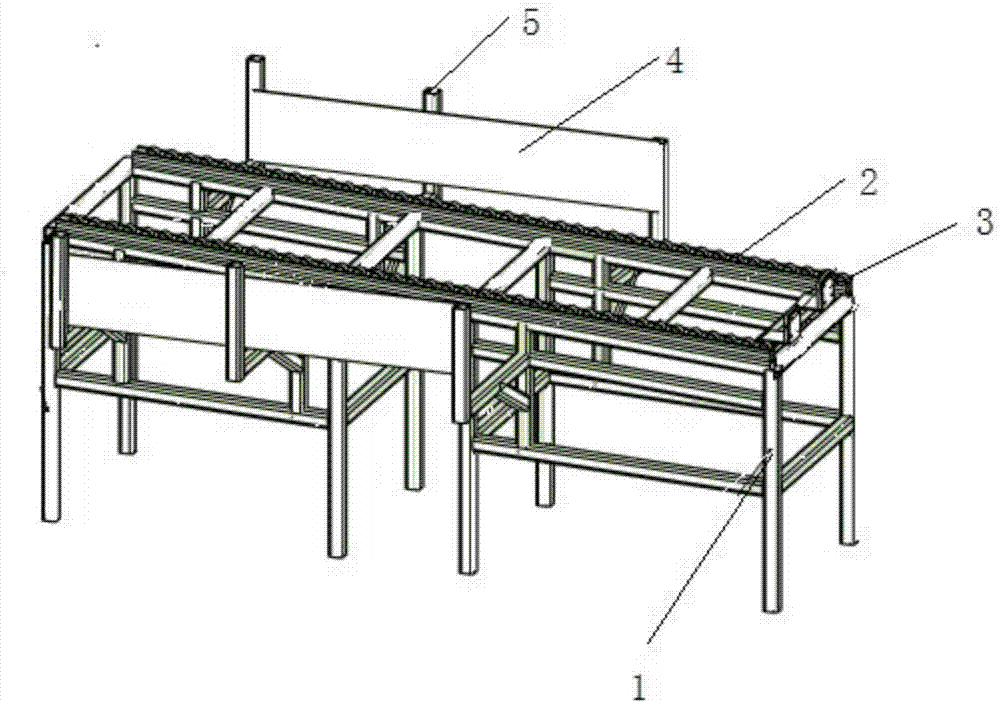

[0016] Please refer to figure 1 , a transmission device used for the production of automobile roofs, comprising a frame 1 with eight pillars, the upper end of the frame 1 is provided with a rectangular frame matching the four sides of the upper surface of the frame 1, and one end of the short side of the rectangular frame is connected to the frame Hinged connection, the two corners of the other end are provided with posts, and the post is provided with two elastic protrusions distributed on different surfaces of the post, the elastic protrusions are arranged symmetrically along the axial direction, and the The elastic protrusions are set in a cylindrical shape, slots matching the posts are provided on the pillars at the two corners of the other end of the frame, and grooves matching the elastic protrusions are provided on the inner wall of the slots. The post is placed in the slot; the upper end of the rectangular frame is provided with fluent strips 2 on both long sides, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com