Magnetic powder clutch gland shaft concentricity auxiliary module

A technology of magnetic powder clutches and auxiliary modules, applied in clutches, fluid clutches, mechanical equipment, etc., can solve problems such as affecting operation, insufficient concentricity, and loosening of fixing bolts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

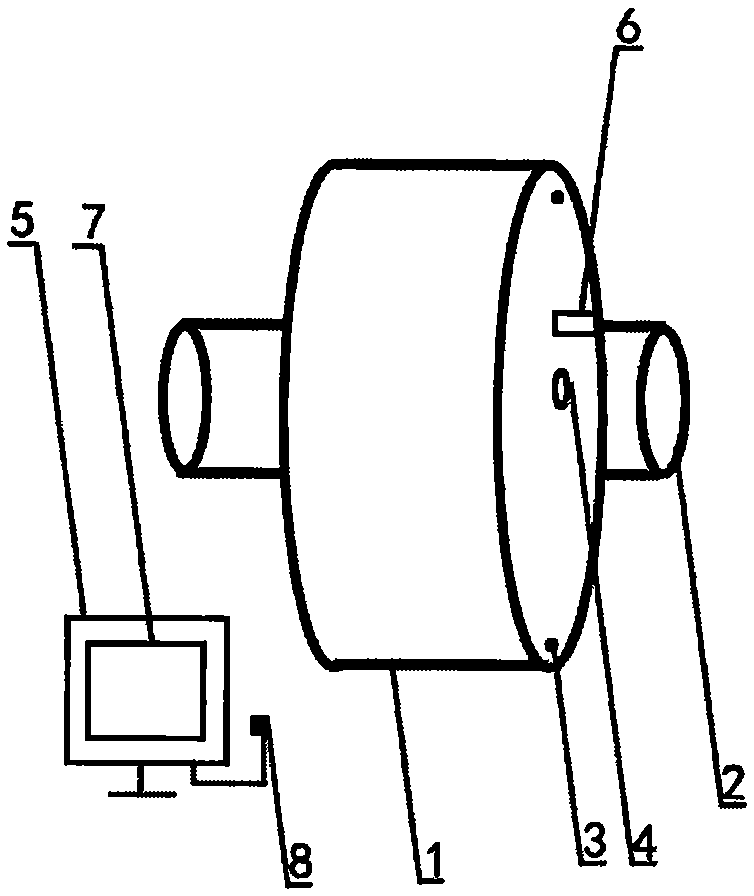

[0012] Embodiment: as shown in the accompanying drawing. The concentricity auxiliary module of the cover shaft of the magnetic powder clutch includes a body (1), on which a rotating shaft module (2), an information generating module (3), an information receiving module (4), and a management module (5) are arranged , during operation, the information generating module (3) is arranged on both sides of the rotating shaft module (2) to form a straight line, the information receiving module (4) receives the distance information of the straight line, and the received information is processed by the management module (5).

[0013] The magnetic powder clutch gland shaft concentricity auxiliary module is provided with an adjustment module (6) on the rotation axis module (2), and when the information generation module (3) and the rotation axis module (2) are not in the same straight line, the rotation axis module is adjusted (2) Location.

[0014] The magnetic powder clutch gland shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com