High-power circulator and microdischarge-resistant design method thereof

A circulator and high-power technology, which is applied in the field of circulator and its anti-micro-discharge design, can solve the problems of large influence on the electrical performance of microwave components and increased loss, and avoid low-pressure discharge, small structure size, and micro-discharge power. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1: High-power Y-junction circulator and its anti-microdischarge design method

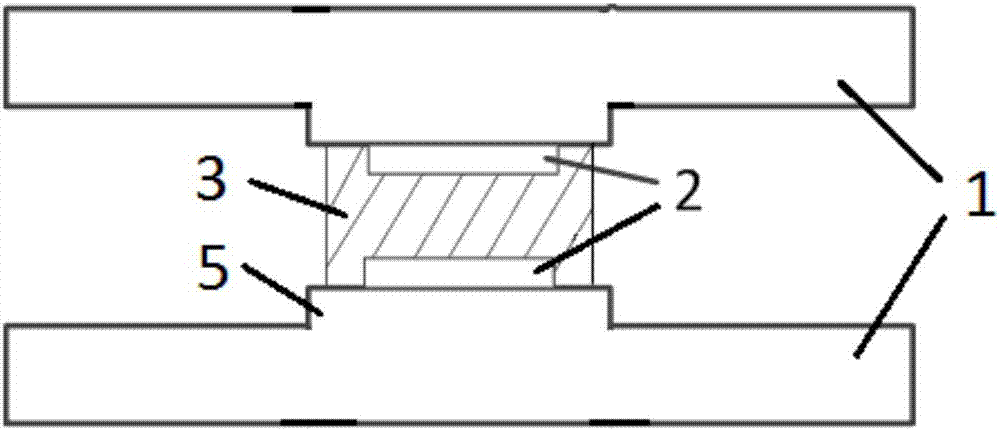

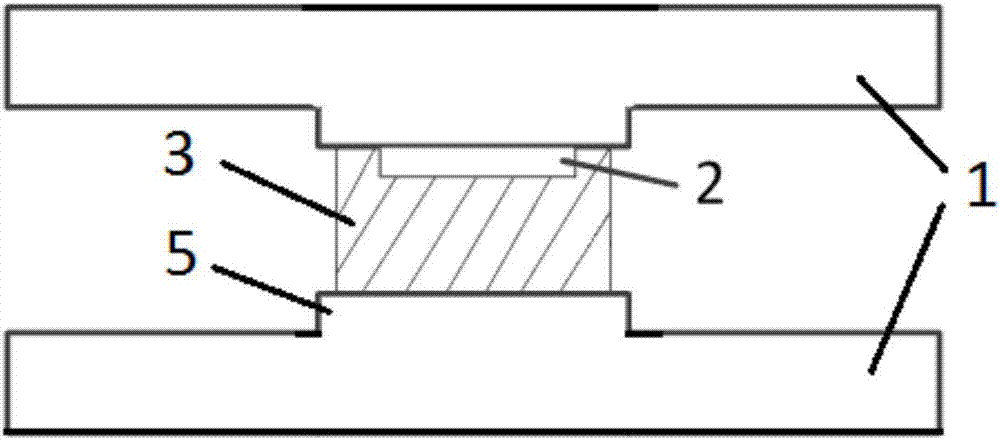

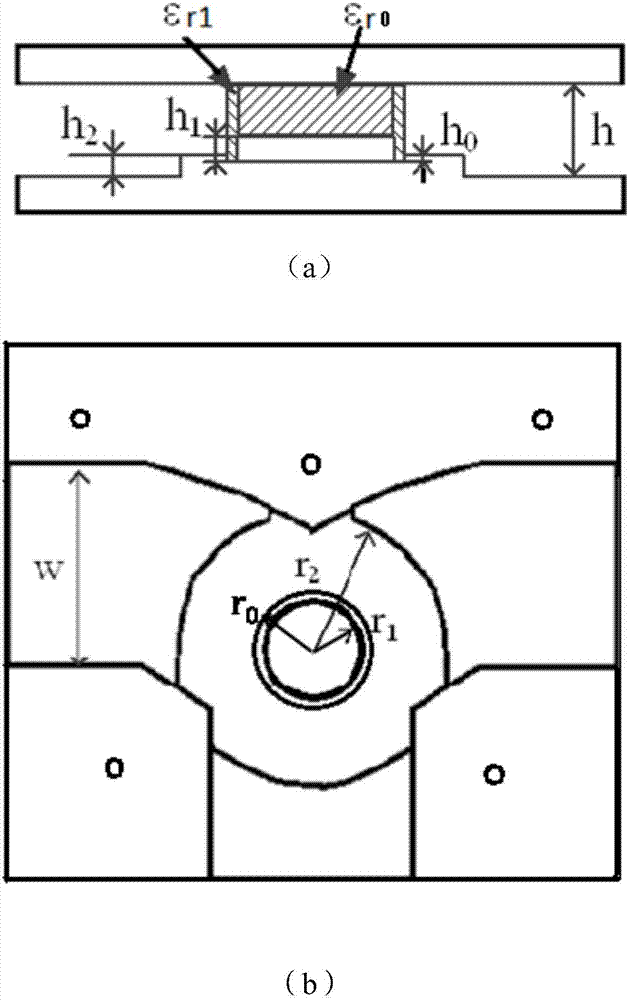

[0047] Such as Figure 5 As shown, the high-power circulator includes a metal cavity 1, a ferrite gyromagnetic substrate 2 and a dielectric slot 3, wherein a metal matching table 5 and a positioning groove 4 are processed on the metal cavity 1, and the ferrite The body gyromagnetic substrate 2 is located in the medium card slot 3, and the medium card slot 3 clamps the 2 ferrite gyromagnetic substrates in the metal cavity 1; the upper cover of the metal cavity 1 is installed on the base, and the upper cover and the A cavity is formed between the bases. The cavity includes a central area loaded with a ferrite gyromagnetic substrate 2 and three ports. The three ports are respectively connected to external lines. When an electromagnetic wave of a certain frequency is incident on a port, the electromagnetic wave It is output by the next port of the ring, and has a certain degree of is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com