An efficient bridge facility

A bridge and high-efficiency technology, applied in the field of high-efficiency bridge facilities, can solve the problems of affecting the cleaning effect, low efficiency, easy mixing and unevenness of water and cleaning agents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

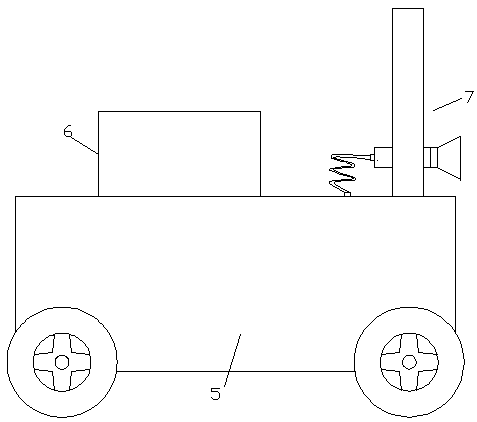

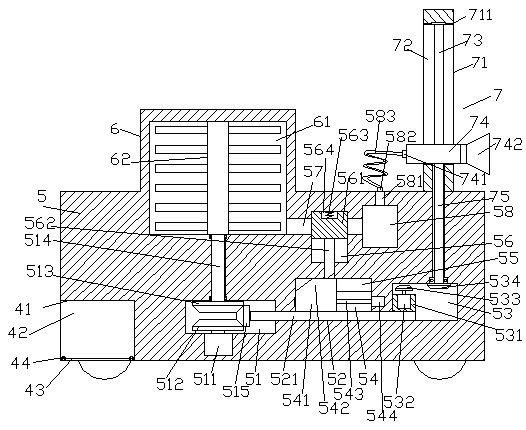

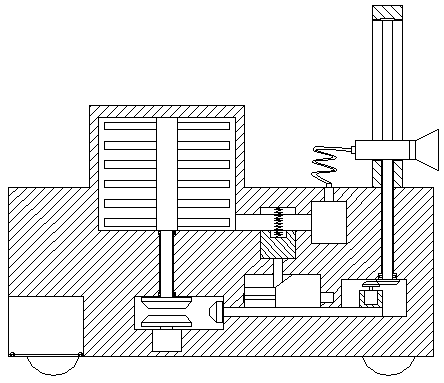

[0021] Such as Figure 1-Figure 4As shown, a high-efficiency bridge facility of the present invention includes a base 5, a liquid storage tank 6 arranged on the top left side of the base 5, and a cleaning device 7 arranged on the top right side of the base 5, the liquid storage The tank 6 is provided with a downwardly extending liquid storage chamber 61, the extended section at the bottom of the liquid storage chamber 61 extends into the base body 5, and a stirrer 62 is connected to the liquid storage chamber 61 in a rotating fit. A first hollow chamber 51 is provided in the base body 5 below the liquid storage chamber 61, and a transmission device is provided in the first hollow chamber 51, and a transmission device is provided in the base body 5 above the right side of the first hollow chamber 51. Guide cavity 54, a second hollow cavity 53 is provided in the base body 5 on the right side of the guide cavity 54, the bottom of the guide cavity 54 is provided with a sliding gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com