Blind plate type circulating packing tool

A blind plate and tool technology, applied in the field of sand flushing of coalbed methane wells, can solve the problems of easy occurrence of sand sticking, high supporting costs, discontinuous sand flushing process, etc., and achieve the effect of saving sand flushing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

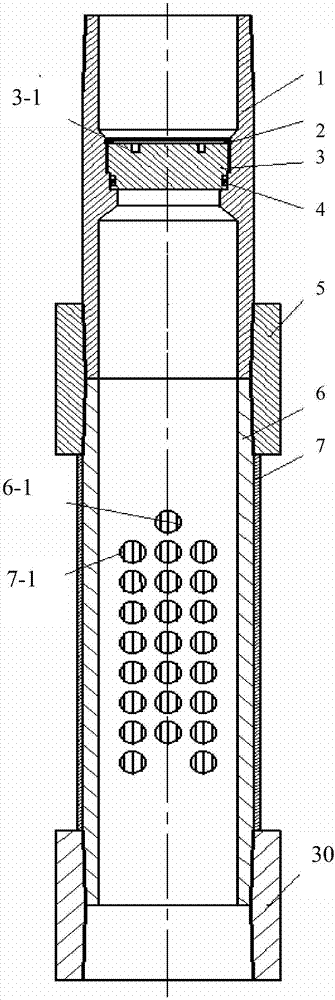

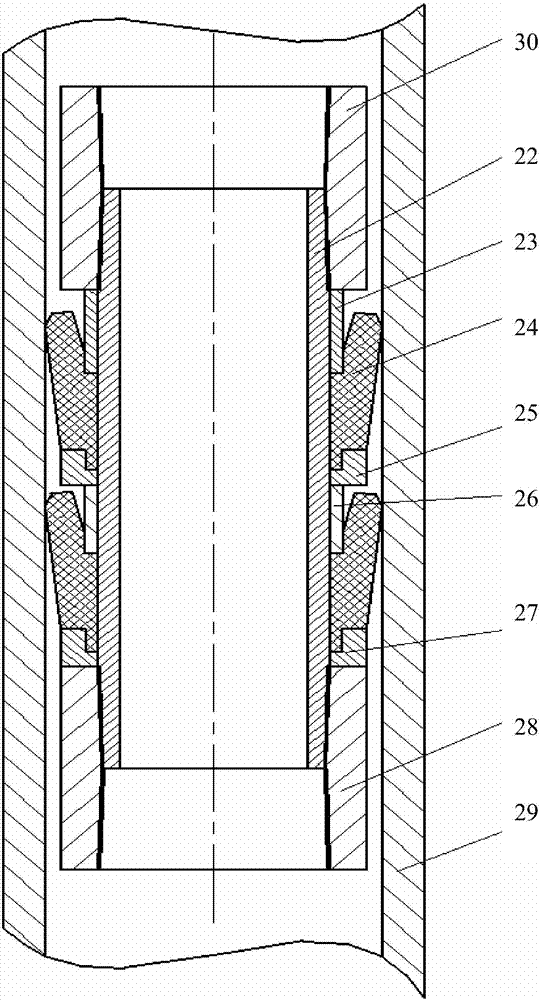

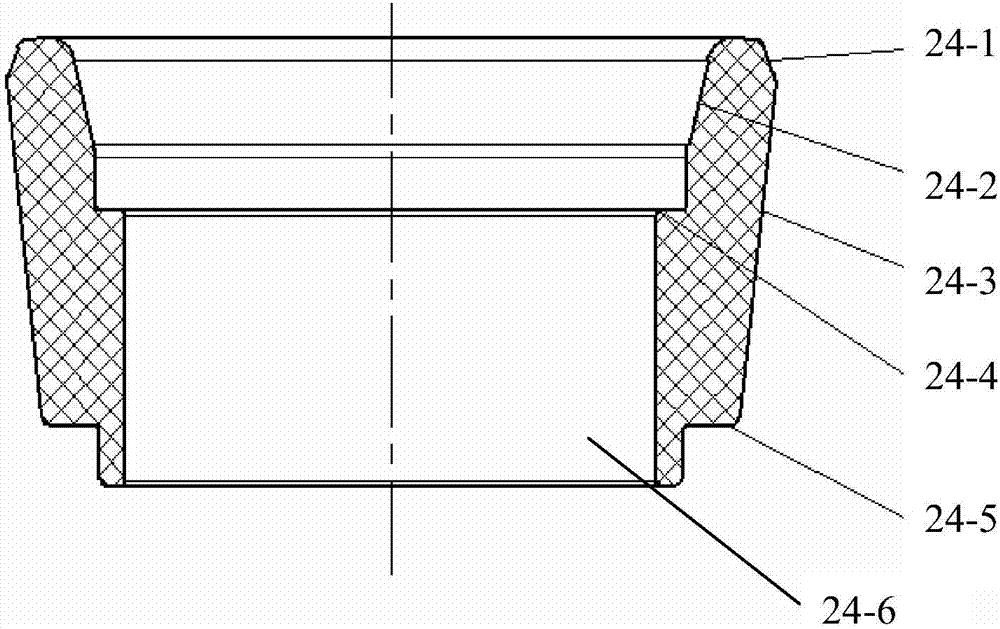

[0021] Such as Figure 1-4 As shown, the blind circulation isolation tool of the present invention includes a blind circulation sub assembly 31 located above and a sealing sub assembly 32 located below. The blind circulation sub assembly 31 and the sealing sub assembly 32 pass through the The connecting pipe 30 of the two outer walls is connected into one;

[0022] Blind plate type circulation nipple assembly 31 includes upper connection pipe 1, retaining spring 2, blind plate 3, sealing ring 4, connector 5, circulation nipple 6, protective sleeve 7, the upper end of upper connection pipe 1 and circulation nipple 6 passes through The connecting head 5 sleeved on the outside of the two is threaded to form a whole. The connecting pipe 30 is connected to the lower end of the circulation nipple 6 through threads. The protective sleeve 7 is designed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com