Test system for simulating fluid temperature and/or pressure quick change and test method thereof

A test system and temperature change technology, which is applied in the field of test systems with rapid changes in temperature and/or pressure, and in the field of test systems that simulate rapid changes in aeroengine bleed air temperature and/or pressure, and can solve the problem of slow pressure adjustment of the test system, gas temperature Change lag, large amount of cooling water, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

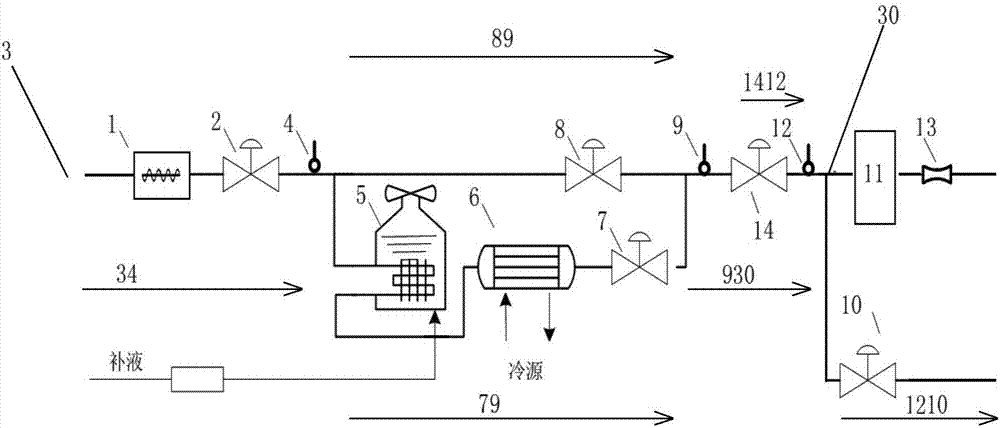

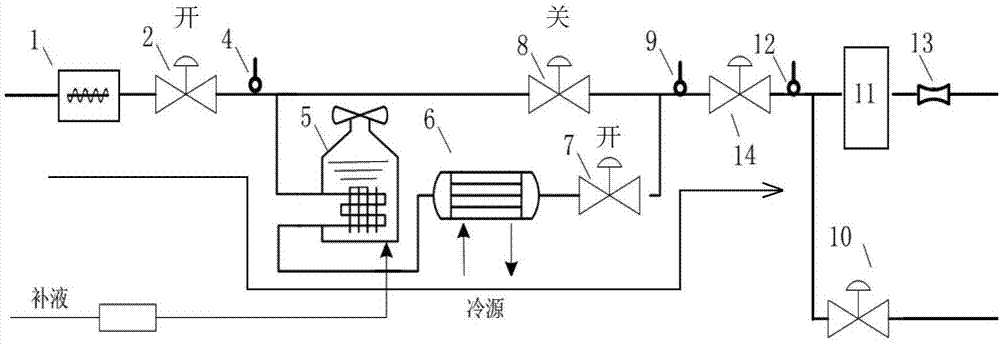

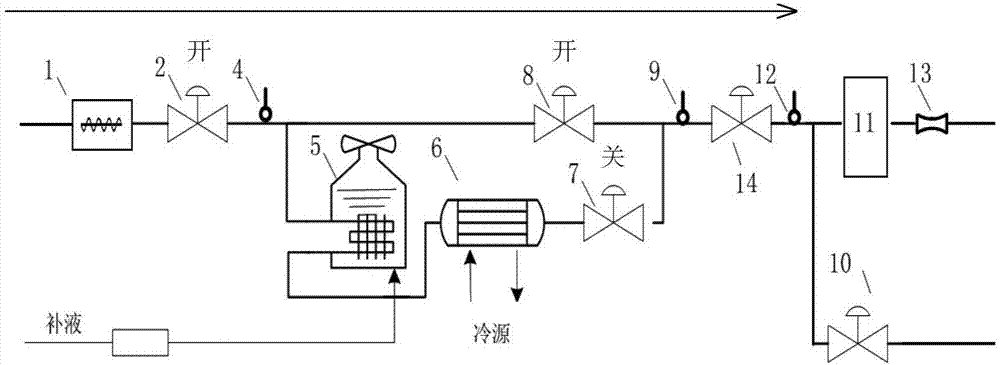

[0032] The present invention will be further described below with reference to the accompanying drawings and embodiments, so as to more clearly understand the inventive principle and beneficial technical effects of the present invention.

[0033] The reference numerals in the drawings of the specification of the present application correspond to the following constitutions in the embodiments:

[0034] 1: heater;

[0035] 2: The first pressure regulator of the high temperature type quick fine adjustment valve;

[0036] 4: the first temperature sensor;

[0037] 5: Evaporator;

[0038] 6: heat exchanger;

[0039] 7: The second pressure regulator of the high temperature type quick fine adjustment valve;

[0040] 8: The third pressure regulator of the high temperature type quick fine adjustment valve;

[0041] 9: the second temperature sensor;

[0042] 10: The fourth pressure regulator of the quick pressure regulating valve;

[0043] 11: Test piece;

[0044] 12: pressure se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com