Refrigerator

A technology for refrigerators and storage rooms, which is applied in the field of refrigerators and can solve the problems that users cannot recognize the functions of sterilization and deodorization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

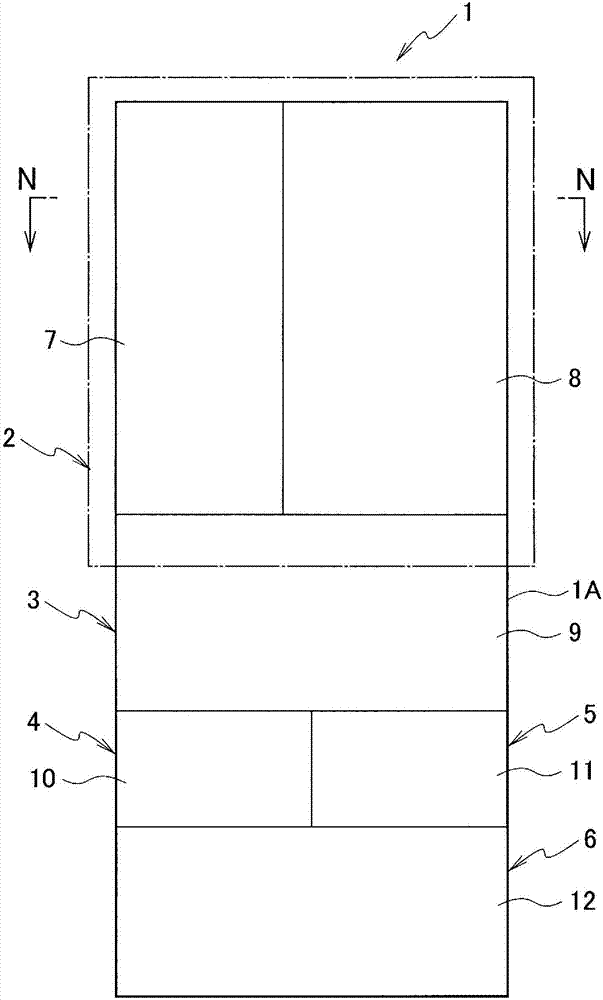

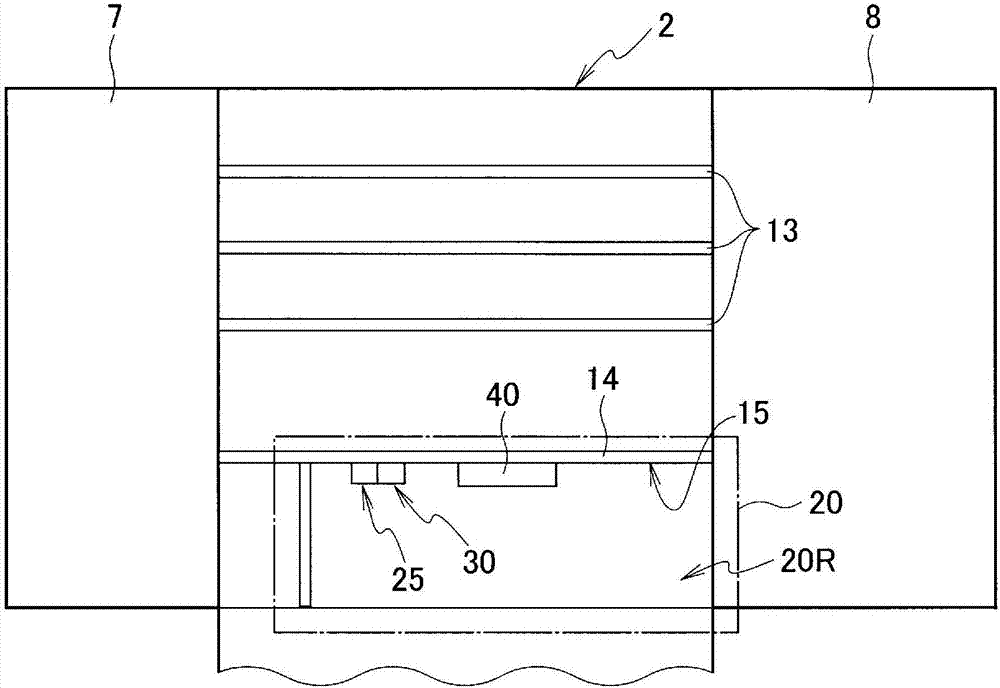

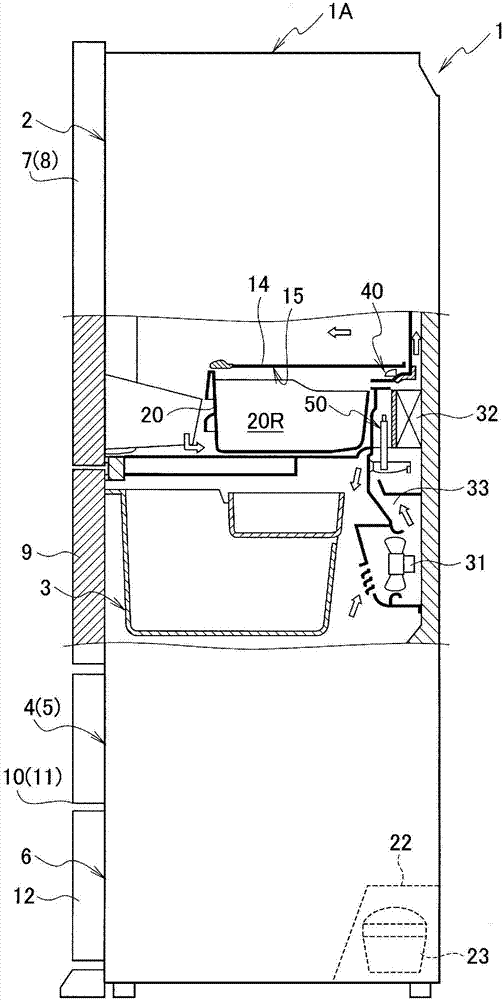

[0036] Hereinafter, modes for implementing the present invention (hereinafter referred to as embodiments) will be described using the drawings.

[0037] figure 1 It is a front view which shows the whole of the refrigerator which concerns on embodiment of this invention. figure 2 is to show the figure 1 It is a front view of a state in which the left door 7 and the right door 8 of the refrigerating compartment 2 of the refrigerator 1 are opened.

[0038] figure 1 and figure 2 The illustrated refrigerator 1 has a main body 1A. The main body 1A of the refrigerator 1 has an outer box made of outer side panels and an inner box made of inner side panels, and a heat-insulating box is arranged between the outer box and the inner box.

[0039] like figure 1 As shown, in the main body 1A, a refrigerating compartment 2 and a vegetable compartment 3 are arranged sequentially from the upper side, and an ice-making compartment 4 and an upper freezer compartment are arranged side by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com