A Calculation Method of Equivalent Thermal Conductivity of Particle Fouling Based on the Characteristics of Porous Media

A technology of equivalent thermal conductivity and porous medium, which is used in calculations, complex mathematical operations, thermal development of materials, etc. It can solve the problems of high measurement cost, unreliable data, and complex methods, and achieve reliable calculation results, simple methods, and effective results. good effect

Active Publication Date: 2020-06-23

NORTHEAST DIANLI UNIVERSITY

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] Aiming at the problems of high cost, complicated method and unreliable data in the existing measurement of thermal resistance of dirt, the present invention is based on image processing technology, considers the porous medium characteristics of granular dirt, obtains the porosity of granular dirt, and proposes a method based on theoretical analysis A calculation method for the equivalent thermal conductivity of granular fouling based on the characteristics of porous media, thereby obtaining its equivalent thermal conductivity, making the research on granular fouling more accurate and standardized, and revealing the mechanism of heat transfer in granular fouling more deeply. established a scientific basis for harm

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment

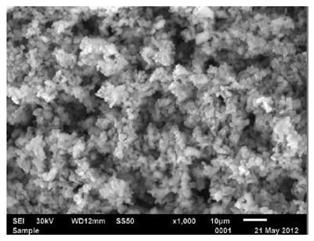

[0071] a. Determine surface porosity of particulate fouling

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the field of the surface particulate fouling coefficient of heat exchange equipment, and discloses a particulate fouling equivalent heat conduction coefficient calculation method based on porous medium characteristics. The method is characterized in that: on the basis of a picture processing method, the porous medium characteristics of the particulate fouling are considered to obtain a particulate fouling porosity, and a particulate fouling equivalent heat conduction coefficient is calculated according to a porous medium particulate fouling equivalent heat conduction coefficient expression obtained through theoretical analysis. By use of the method, the problems of high measurement cost and unreliable data for existing fouling thermal resistance are solved, particulate fouling surface research is more accurate and normative so as to more deeply disclose a transfer mechanism of heat in the particulate fouling, a new approach is opened up for the calculation of the particulate fouling thermal resistance, and a scientific basis is laid for reducing fouling damages.

Description

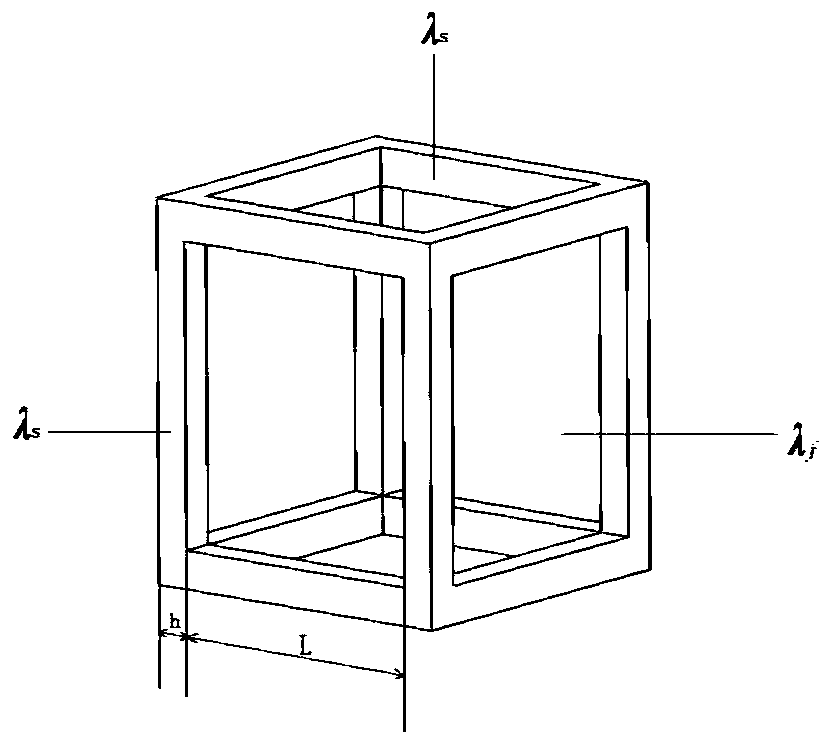

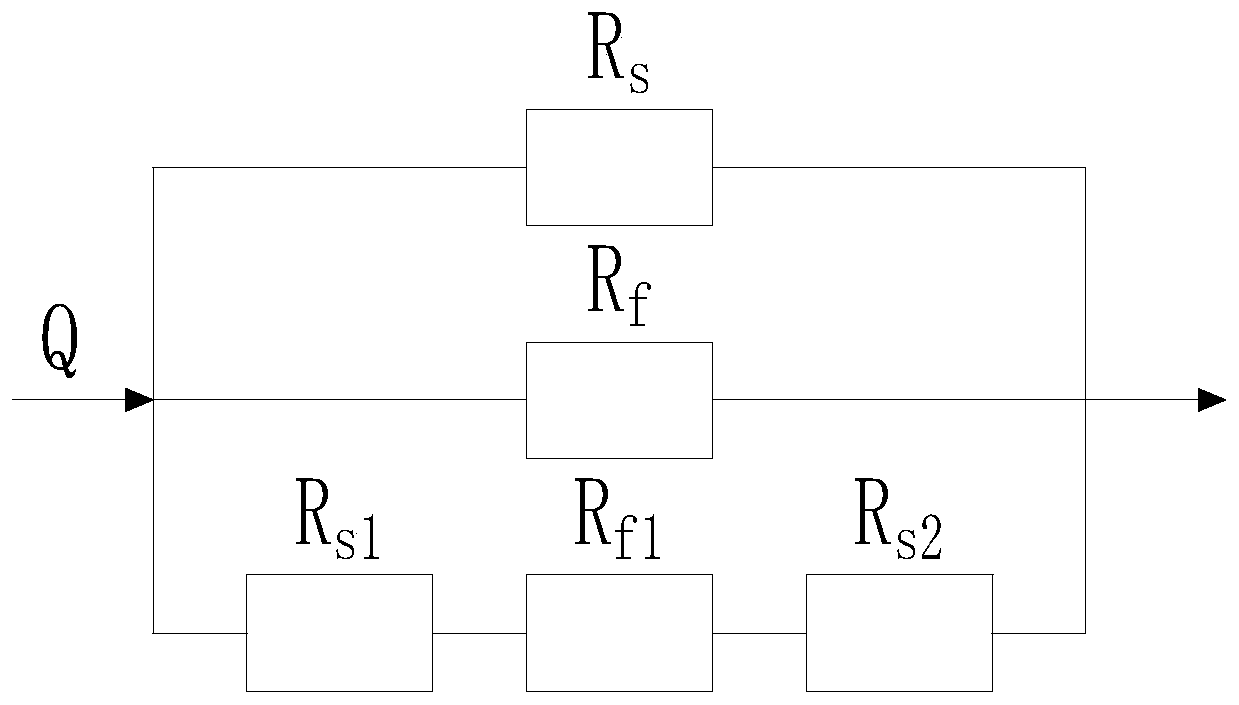

technical field [0001] The invention relates to the field of thermal conductivity of particle dirt on the surface of heat exchange equipment, and relates to a method for calculating the equivalent thermal conductivity of particle dirt based on the characteristics of porous media. Background technique [0002] Heat exchange equipment is one of the equipment frequently used in industrial production and daily life. During operation, due to the deposition of dirt on the surface of the heat exchange equipment, the heat exchange capacity of the equipment will deteriorate. In severe cases, the aging of the heat exchange equipment will be accelerated and the service life of the heat exchange equipment will be shortened. The service life will even affect the safe operation of heat exchange equipment. The economy of the heat exchange equipment is greatly reduced, the operating cost is increased, and a lot of energy is wasted. Therefore, the calculation of the thermal conductivity of ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G06F17/10G06T7/00G01N25/20

CPCG01N25/20G06T7/0004G06T2207/30108G16Z99/00

Inventor 张仲彬曹丽华李勇姜铁骝胡鹏飞王艳红韩为李盼

Owner NORTHEAST DIANLI UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com